Merge branch 'main' into dev/bbl-network-upd

|

|

@ -8,7 +8,7 @@

|

|||

},

|

||||

"options": ["--platform=linux/amd64"]

|

||||

},

|

||||

"runArgs": ["--env-file", "/tmp/devcontainer.env", "--platform=linux/amd64"],

|

||||

"runArgs": ["--platform=linux/amd64"],

|

||||

"features": {

|

||||

"ghcr.io/devcontainers/features/desktop-lite:1": {

|

||||

"password": "orca"

|

||||

|

|

@ -23,9 +23,6 @@

|

|||

"-DBBL_INTERNAL_TESTING=0",

|

||||

"-DSLIC3R_STATIC=1",

|

||||

"-DCMAKE_PREFIX_PATH=${workspaceFolder}/deps/build/destdir/usr/local"

|

||||

],

|

||||

"cmake.buildToolArgs": [

|

||||

"-l${containerEnv:CORES}"

|

||||

]

|

||||

},

|

||||

|

||||

|

|

@ -47,10 +44,6 @@

|

|||

"otherPortsAttributes": {

|

||||

"onAutoForward": "ignore"

|

||||

},

|

||||

|

||||

"initializeCommand": {

|

||||

"Setup Temporary Env File": "echo \"CORES=`nproc --all`\" > /tmp/devcontainer.env"

|

||||

},

|

||||

"onCreateCommand": {

|

||||

"Set postCreate executable flag": "chmod +x .devcontainer/postCreate.sh"

|

||||

},

|

||||

|

|

|

|||

219

README.md

|

|

@ -1,135 +1,130 @@

|

|||

|

||||

<h1> <p "font-size:200px;"><img align="left" src="https://github.com/SoftFever/OrcaSlicer/blob/main/resources/images/OrcaSlicer.ico" width="100"> Orca Slicer</p> </h1>

|

||||

|

||||

[](https://github.com/SoftFever/OrcaSlicer/actions/workflows/build_all.yml)

|

||||

<br>Orca Slicer is an open source slicer for FDM printers.

|

||||

|

||||

## Follow Us

|

||||

Stay connected with us:

|

||||

Orca Slicer is an open source Next-Gen Slicing Software for Precision 3D Prints.

|

||||

Optimize your prints with ultra-fast slicing, intelligent support generation, and seamless printer compatibility—engineered for perfection.

|

||||

|

||||

[](https://twitter.com/real_OrcaSlicer)

|

||||

## Official links and community

|

||||

|

||||

Join our Discord community here:<br>

|

||||

<a href="https://discord.gg/P4VE9UY9gJ"><img src="https://img.shields.io/static/v1?message=Discord&logo=discord&label=&color=7289DA&logoColor=white&labelColor=&style=for-the-badge" height="35" alt="discord logo"/> </a>

|

||||

|

||||

<h3>🚨🚨🚨Important Security Alert🚨🚨🚨</h3>

|

||||

#### Official Website:

|

||||

<a href="https://orcaslicer.com/" style="font-size:2em;"><strong>orcaslicer.com</strong></a>

|

||||

|

||||

The only official platforms for OrcaSlicer are **our GitHub project page**, <a href="https://orcaslicer.com/">**orcaslicer.com**</a>, the <a href="https://discord.gg/P4VE9UY9gJ">**official Discord channel**</a>, and the <a href="https://twitter.com/real_OrcaSlicer">**official Twitter/X account**</a>.

|

||||

#### Github Repository:

|

||||

<a href="https://github.com/SoftFever/OrcaSlicer"><img src="https://img.shields.io/badge/OrcaSlicer-181717?style=flat&logo=github&logoColor=white" width="200" alt="GitHub Logo"/> </a>

|

||||

|

||||

Please be aware that "**orcaslicer.net**", "**orcaslicer.co**" or "**orca-slicer.com**" are NOT an official website for OrcaSlicer and may be potentially malicious. These sites appear to use AI-generated content, lacking genuine context and seems to exist solely to profit from advertisements. Worse, it may redirect download links to harmful sources. For your safety, avoid downloading OrcaSlicer from this site as the links may be compromised.

|

||||

#### Follow us:

|

||||

<a href="https://twitter.com/real_OrcaSlicer"><img src="https://img.shields.io/badge/real__OrcaSlicer-000000?style=flat&logo=x&logoColor=white" width="200" alt="X Logo"/> </a>

|

||||

|

||||

If you see the above sites in your searches, report them as spam or unsafe to the search engine. This small action will assist everyone.

|

||||

#### Join our Discord community:

|

||||

<a href="https://discord.gg/P4VE9UY9gJ"><img src="https://img.shields.io/badge/-Discord-5865F2?style=flat&logo=discord&logoColor=fff" width="200" alt="discord logo"/> </a>

|

||||

|

||||

We deeply value our OrcaSlicer community and appreciate all the social groups that support us. However, it is crucial to address the risk posed by any group that falsely claims to be official or misleads its members. If you encounter such a group or are part of one, please assist by encouraging the group owner to add a clear disclaimer or by alerting its members.

|

||||

|

||||

|

||||

|

||||

Thank you for your vigilance and support in keeping our community safe!

|

||||

> [!CAUTION]

|

||||

> There are multiple unofficial and potentially malicious websites pretending to be related to OrcaSlicer. These sites may redirect you to dangerous downloads or contain misleading information.

|

||||

>

|

||||

> If you come across any of these in search results, please report them as unsafe or spam to help keep the community secure.

|

||||

|

||||

# Main features

|

||||

- Auto-calibration for all printers

|

||||

- Sandwich (inner-outer-inner) mode - An improved version of the `External Perimeters First` mode

|

||||

- [Precise wall](https://github.com/SoftFever/OrcaSlicer/wiki/Precise-wall)

|

||||

- Polyholes conversion support: [SuperSlicer Wiki: Polyholes](https://github.com/supermerill/SuperSlicer/wiki/Polyholes)

|

||||

- Klipper support

|

||||

- More granular controls

|

||||

- Additional features can be found in the [change notes](https://github.com/SoftFever/OrcaSlicer/releases/)

|

||||

|

||||

- **[Advanced Calibration Tools](https://github.com/SoftFever/OrcaSlicer/wiki/Calibration)**

|

||||

Comprehensive suite: temperature towers, flow rate, retraction & more for optimal performance.

|

||||

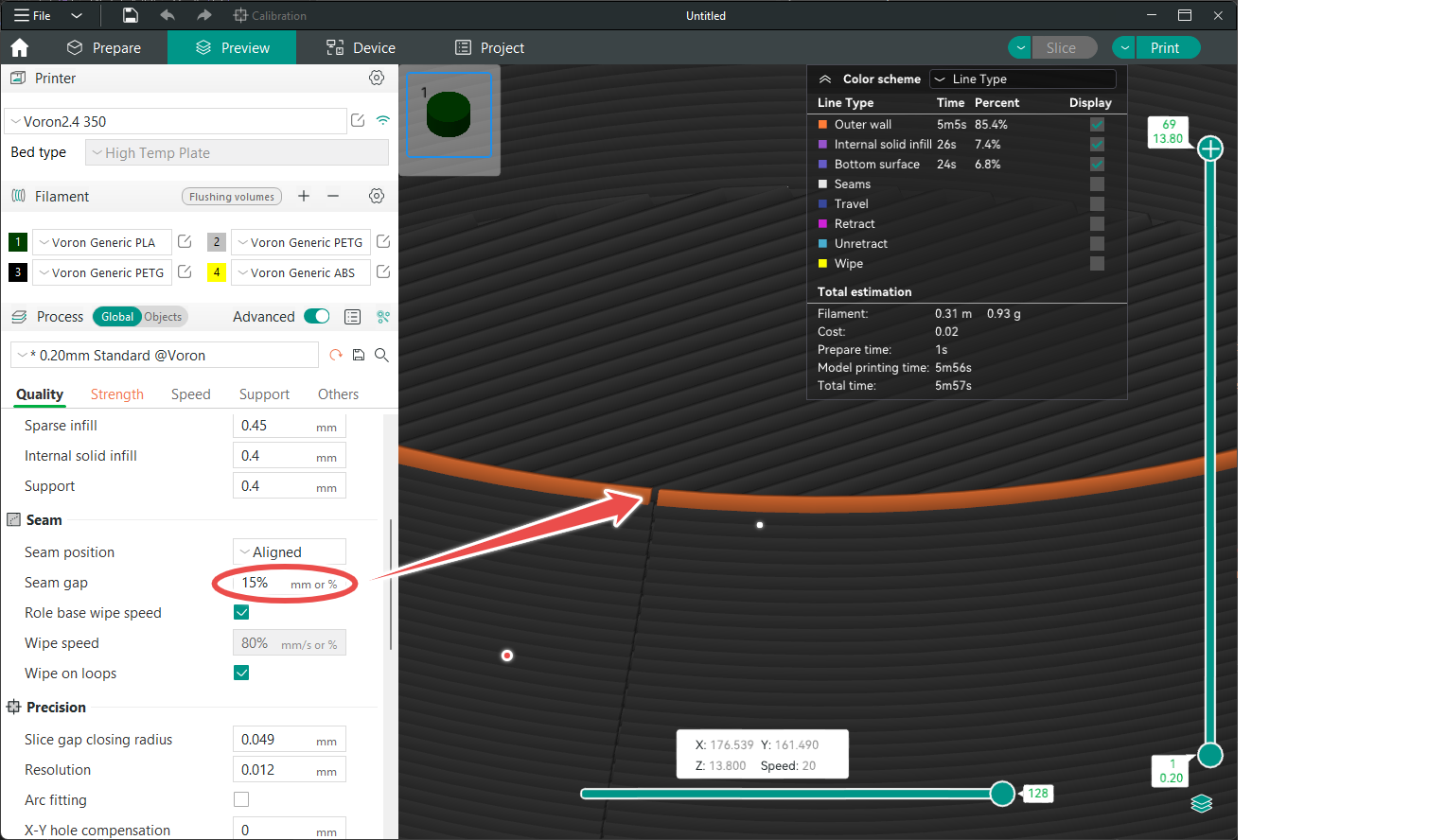

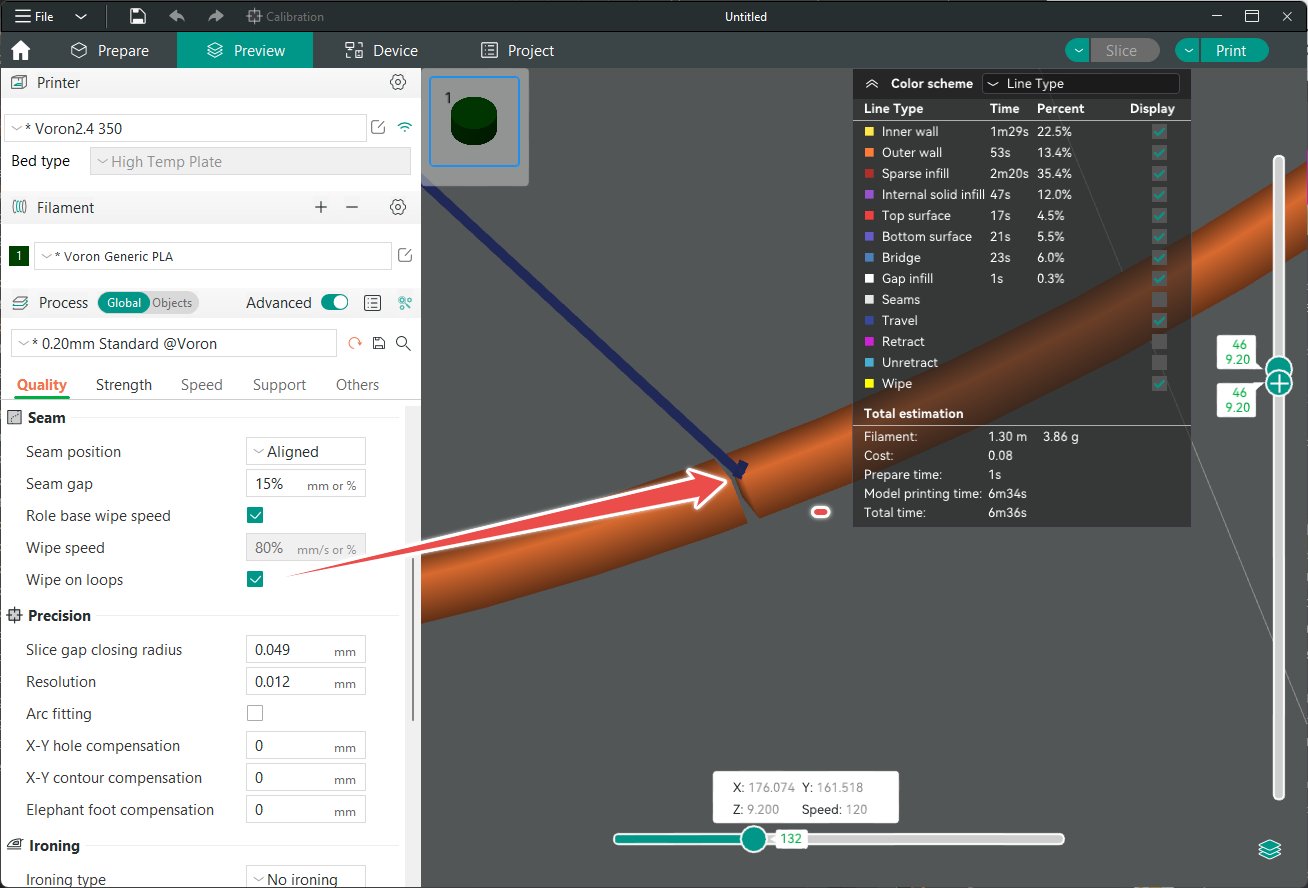

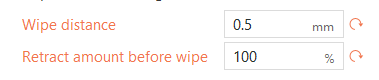

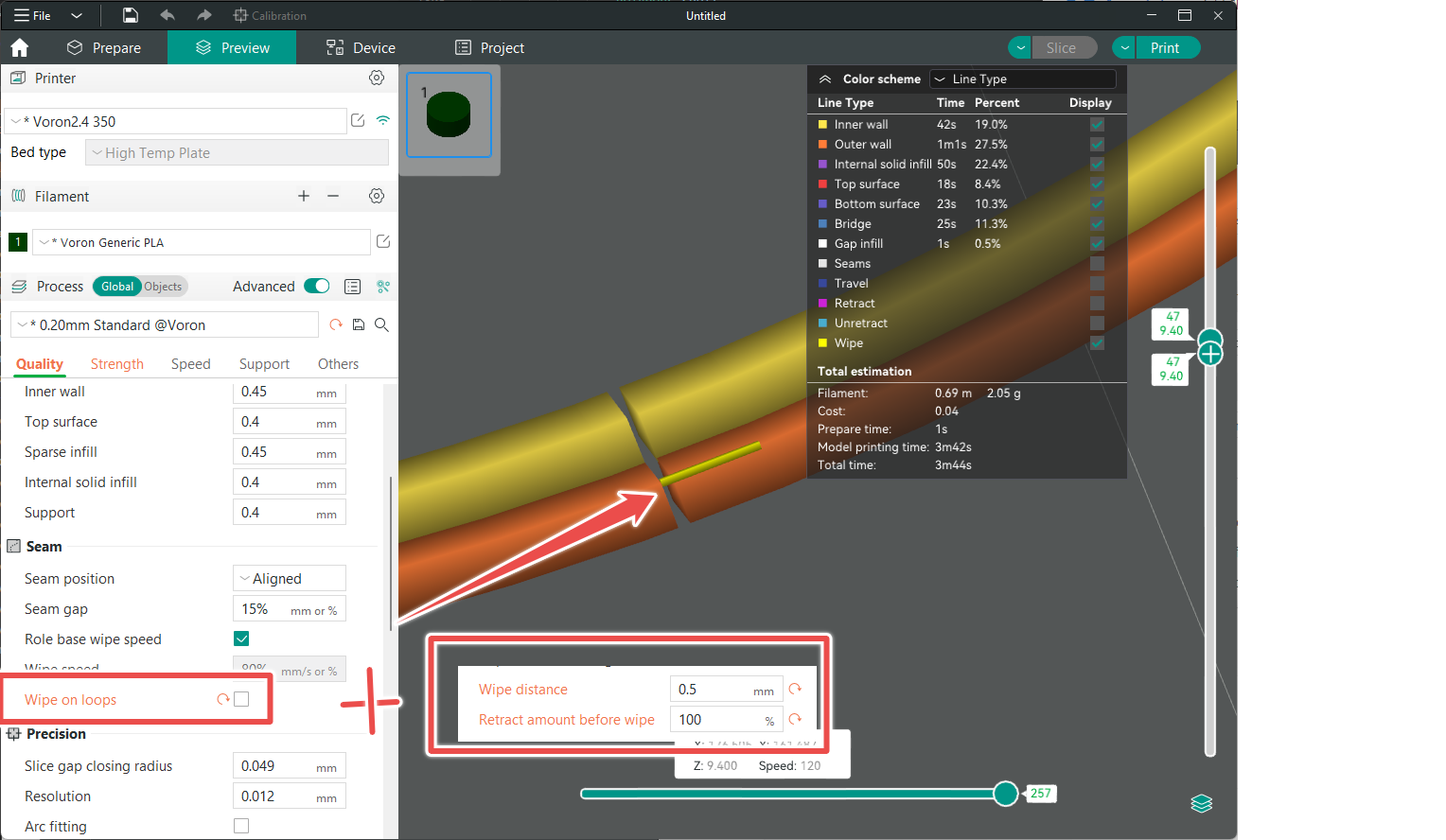

- **[Precise Wall](https://github.com/SoftFever/OrcaSlicer/wiki/Precise-wall) and [Seam Control](https://github.com/SoftFever/OrcaSlicer/wiki/quality_settings_seam)**

|

||||

Adjust outer wall spacing and apply scarf seams to enhance print accuracy.

|

||||

- **Sandwich Mode and [SuperSlicer Polyholes](https://github.com/supermerill/SuperSlicer/wiki/Polyholes) Support**

|

||||

Use varied infill patterns and accurate hole shapes for improved clarity.

|

||||

- **Overhang and Support Optimization**

|

||||

Modify geometry for printable overhangs with precise support placement.

|

||||

- **Granular Controls and Customization**

|

||||

Fine-tune print speed, layer height, pressure, and temperature with precision.

|

||||

- **Network Printer Support**

|

||||

Seamless integration with Klipper, PrusaLink, and OctoPrint for remote control.

|

||||

- **Mouse Ear Brims & Adaptive Bed Mesh**

|

||||

Automatic brims and adaptive mesh calibration ensure consistent adhesion.

|

||||

- **User-Friendly Interface**

|

||||

Intuitive drag-and-drop design with pre-made profiles for popular printers.

|

||||

- **Open-Source & Community Driven**

|

||||

Regular updates fueled by continuous community contributions.

|

||||

- **Wide Printer Compatibility**

|

||||

Supports a broad range of printers: Bambu Lab, Prusa, Creality, Voron, and more.

|

||||

- Additional features can be found in the [change notes](https://github.com/SoftFever/OrcaSlicer/releases/)

|

||||

|

||||

# Wiki

|

||||

|

||||

The wiki below aims to provide a detailed explanation of the slicer settings, including how to maximize their use and how to calibrate and set up your printer.

|

||||

|

||||

Please note that the wiki is a work in progress. We appreciate your patience as we continue to develop and improve it!

|

||||

|

||||

**[Access the wiki here](https://github.com/SoftFever/OrcaSlicer/wiki)**

|

||||

**[Access the wiki here](https://github.com/SoftFever/OrcaSlicer/wiki)**

|

||||

**[Contribute to the wiki](https://github.com/SoftFever/OrcaSlicer/wiki/How-to-wiki)**

|

||||

|

||||

# Download

|

||||

|

||||

### Stable Release

|

||||

## Stable Release

|

||||

📥 **[Download the Latest Stable Release](https://github.com/SoftFever/OrcaSlicer/releases/latest)**

|

||||

Visit our GitHub Releases page for the latest stable version of Orca Slicer, recommended for most users.

|

||||

|

||||

### Nightly Builds

|

||||

## Nightly Builds

|

||||

🌙 **[Download the Latest Nightly Build](https://github.com/SoftFever/OrcaSlicer/releases/tag/nightly-builds)**

|

||||

Explore the latest developments in Orca Slicer with our nightly builds. Feedback on these versions is highly appreciated.

|

||||

|

||||

|

||||

# How to install

|

||||

**Windows**:

|

||||

1. Download the installer for your preferred version from the [releases page](https://github.com/SoftFever/OrcaSlicer/releases).

|

||||

- *For convenience there is also a portable build available.*

|

||||

- *If you have troubles to run the build, you might need to install following runtimes:*

|

||||

- [MicrosoftEdgeWebView2RuntimeInstallerX64](https://github.com/SoftFever/OrcaSlicer/releases/download/v1.0.10-sf2/MicrosoftEdgeWebView2RuntimeInstallerX64.exe)

|

||||

- [Details of this runtime](https://aka.ms/webview2)

|

||||

- [Alternative Download Link Hosted by Microsoft](https://go.microsoft.com/fwlink/p/?LinkId=2124703)

|

||||

- [vcredist2019_x64](https://github.com/SoftFever/OrcaSlicer/releases/download/v1.0.10-sf2/vcredist2019_x64.exe)

|

||||

- [Alternative Download Link Hosted by Microsoft](https://aka.ms/vs/17/release/vc_redist.x64.exe)

|

||||

- This file may already be available on your computer if you've installed visual studio. Check the following location: `%VCINSTALLDIR%Redist\MSVC\v142`

|

||||

## Windows

|

||||

Download the **Windows Installer exe** for your preferred version from the [releases page](https://github.com/SoftFever/OrcaSlicer/releases).

|

||||

|

||||

- *For convenience there is also a portable build available.*

|

||||

<details>

|

||||

<summary>Troubleshooting</summary>

|

||||

|

||||

- *If you have troubles to run the build, you might need to install following runtimes:*

|

||||

- [MicrosoftEdgeWebView2RuntimeInstallerX64](https://github.com/SoftFever/OrcaSlicer/releases/download/v1.0.10-sf2/MicrosoftEdgeWebView2RuntimeInstallerX64.exe)

|

||||

- [Details of this runtime](https://aka.ms/webview2)

|

||||

- [Alternative Download Link Hosted by Microsoft](https://go.microsoft.com/fwlink/p/?LinkId=2124703)

|

||||

- [vcredist2019_x64](https://github.com/SoftFever/OrcaSlicer/releases/download/v1.0.10-sf2/vcredist2019_x64.exe)

|

||||

- [Alternative Download Link Hosted by Microsoft](https://aka.ms/vs/17/release/vc_redist.x64.exe)

|

||||

- This file may already be available on your computer if you've installed visual studio. Check the following location: `%VCINSTALLDIR%Redist\MSVC\v142`

|

||||

</details>

|

||||

|

||||

Windows Package Manager:

|

||||

```shell

|

||||

winget install --id=SoftFever.OrcaSlicer --e

|

||||

```

|

||||

|

||||

## Mac:

|

||||

1. Download the DMG for your computer: `arm64` version for Apple Silicon and `x86_64` for Intel CPU.

|

||||

2. Drag OrcaSlicer.app to Application folder.

|

||||

3. *If you want to run a build from a PR, you also need to follow the instructions below:*

|

||||

<details>

|

||||

<summary>Quarantine</summary>

|

||||

|

||||

**Mac**:

|

||||

1. Download the DMG for your computer: `arm64` version for Apple Silicon and `x86_64` for Intel CPU.

|

||||

2. Drag OrcaSlicer.app to Application folder.

|

||||

3. *If you want to run a build from a PR, you also need to follow the instructions below:*

|

||||

<details quarantine>

|

||||

- Option 1 (You only need to do this once. After that the app can be opened normally.):

|

||||

- Step 1: Hold _cmd_ and right click the app, from the context menu choose **Open**.

|

||||

- Step 2: A warning window will pop up, click _Open_

|

||||

|

||||

- Option 2:

|

||||

Execute this command in terminal: `xattr -dr com.apple.quarantine /Applications/OrcaSlicer.app`

|

||||

```console

|

||||

softfever@mac:~$ xattr -dr com.apple.quarantine /Applications/OrcaSlicer.app

|

||||

- Step 2: A warning window will pop up, click _Open_

|

||||

|

||||

- Option 2:

|

||||

Execute this command in terminal:

|

||||

```shell

|

||||

xattr -dr com.apple.quarantine /Applications/OrcaSlicer.app`

|

||||

```

|

||||

- Option 3:

|

||||

- Option 3:

|

||||

- Step 1: open the app, a warning window will pop up

|

||||

|

||||

- Step 2: in `System Settings` -> `Privacy & Security`, click `Open Anyway`:

|

||||

|

||||

|

||||

- Step 2: in `System Settings` -> `Privacy & Security`, click `Open Anyway`:

|

||||

|

||||

</details>

|

||||

|

||||

**Linux (Ubuntu)**:

|

||||

1. If you run into trouble executing it, try this command in the terminal:

|

||||

|

||||

## Linux (Ubuntu):

|

||||

1. If you run into trouble executing it, try this command in the terminal:

|

||||

`chmod +x /path_to_appimage/OrcaSlicer_Linux.AppImage`

|

||||

|

||||

# How to compile

|

||||

- Windows 64-bit

|

||||

- Tools needed: Visual Studio 2019, Cmake, git, git-lfs, Strawberry Perl.

|

||||

- You will require cmake version 3.14 or later, which is available [on their website](https://cmake.org/download/).

|

||||

- Strawberry Perl is [available on their GitHub repository](https://github.com/StrawberryPerl/Perl-Dist-Strawberry/releases/).

|

||||

- Run `build_release.bat` in `x64 Native Tools Command Prompt for VS 2019`

|

||||

- Note: Don't forget to run `git lfs pull` after cloning the repository to download tools on Windows

|

||||

|

||||

- Mac 64-bit

|

||||

- Tools needed: Xcode, Cmake, git, gettext, libtool, automake, autoconf, texinfo

|

||||

- You can install most of them by running `brew install cmake gettext libtool automake autoconf texinfo`

|

||||

- If you haven't since upgrading Xcode, start Xcode and install macOS build support.

|

||||

- run `build_release_macos.sh`

|

||||

- open `build_arm64/OrcaSlicer/OrcaSlicer.app`

|

||||

- To build and debug in Xcode:

|

||||

- run `Xcode.app`

|

||||

- open ``build_`arch`/OrcaSlicer.Xcodeproj``

|

||||

- menu bar: Product => Scheme => OrcaSlicer

|

||||

- menu bar: Product => Scheme => Edit Scheme...

|

||||

- Run => Info tab => Build Configuration: `RelWithDebInfo`

|

||||

- Run => Options tab => Document Versions: uncheck `Allow debugging when browsing versions`

|

||||

- menu bar: Product => Run

|

||||

# How to Compile

|

||||

All updated build instructions for Windows, macOS, and Linux are now available on the official [OrcaSlicer Wiki - How to build](https://github.com/SoftFever/OrcaSlicer/wiki/How-to-build) page.

|

||||

|

||||

- Linux (All Distros)

|

||||

- Docker

|

||||

- Dependencies: Docker [Installation Instructions](https://www.docker.com/get-started/), git

|

||||

- clone this repository `git clone https://github.com/SoftFever/OrcaSlicer`

|

||||

- run `cd OrcaSlicer`

|

||||

- run `./DockerBuild.sh`

|

||||

- To run OrcaSlicer:

|

||||

- run `./DockerRun.sh`

|

||||

- For most common errors, open `DockerRun.sh` and read the comments.

|

||||

- Ubuntu

|

||||

- Dependencies **Will be auto installed with the shell script**: `libmspack-dev libgstreamerd-3-dev libsecret-1-dev libwebkit2gtk-4.0-dev libosmesa6-dev libssl-dev libcurl4-openssl-dev eglexternalplatform-dev libudev-dev libdbus-1-dev extra-cmake-modules libgtk2.0-dev libglew-dev libudev-dev libdbus-1-dev cmake git texinfo`

|

||||

- run 'sudo ./BuildLinux.sh -u'

|

||||

- run './BuildLinux.sh -dsi'

|

||||

Please refer to the wiki to ensure you're following the latest and most accurate steps for your platform.

|

||||

|

||||

# Note:

|

||||

# Klipper Note:

|

||||

If you're running Klipper, it's recommended to add the following configuration to your `printer.cfg` file.

|

||||

```

|

||||

```gcode

|

||||

# Enable object exclusion

|

||||

[exclude_object]

|

||||

|

||||

|

|

@ -139,53 +134,49 @@ resolution: 0.1

|

|||

```

|

||||

|

||||

# Supports

|

||||

**Orca Slicer** is an open-source project and I'm deeply grateful to all my sponsors and backers.

|

||||

Their generous support enables me to purchase filaments and other essential 3D printing materials for the project.

|

||||

**Orca Slicer** is an open-source project and I'm deeply grateful to all my sponsors and backers.

|

||||

Their generous support enables me to purchase filaments and other essential 3D printing materials for the project.

|

||||

Thank you! :)

|

||||

|

||||

### Sponsors:

|

||||

## Sponsors:

|

||||

<table>

|

||||

<tr>

|

||||

<td>

|

||||

<a href="https://qidi3d.com/">

|

||||

<img src="SoftFever_doc\sponsor_logos\QIDI.png" alt="QIDI" width="96" height="">

|

||||

<a href="https://qidi3d.com/" style="display:inline-block; border-radius:8px; background:#fff;">

|

||||

<img src="SoftFever_doc\sponsor_logos\QIDI.png" alt="QIDI" width="100" height="100">

|

||||

</a>

|

||||

</td>

|

||||

<td>

|

||||

<a href="https://bigtree-tech.com/">

|

||||

<img src="SoftFever_doc\sponsor_logos\BigTreeTech.png" alt="BIGTREE TECH" width="96" height="">

|

||||

<a href="https://bigtree-tech.com/" style="display:inline-block; border-radius:8px; background:#222;">

|

||||

<img src="SoftFever_doc\sponsor_logos\BigTreeTech.png" alt="BIGTREE TECH" width="100" height="100">

|

||||

</a>

|

||||

</td>

|

||||

</tr>

|

||||

</table>

|

||||

|

||||

### Backers:

|

||||

**Ko-fi supporters**: [Backers list](https://github.com/user-attachments/files/16147016/Supporters_638561417699952499.csv)

|

||||

|

||||

## Support me

|

||||

<a href="https://github.com/sponsors/SoftFever"><img src="https://img.shields.io/static/v1?label=Sponsor&message=%E2%9D%A4&logo=GitHub&color=%23fe8e86" width="130"></a>

|

||||

|

||||

<a href="https://ko-fi.com/G2G5IP3CP"><img src="https://ko-fi.com/img/githubbutton_sm.svg" width="200"></a>

|

||||

|

||||

[](https://paypal.me/softfever3d)

|

||||

## Backers:

|

||||

**Ko-fi supporters** ☕: [Backers list](https://github.com/user-attachments/files/16147016/Supporters_638561417699952499.csv)

|

||||

|

||||

## Support me

|

||||

<a href="https://github.com/sponsors/SoftFever"><img src="https://img.shields.io/badge/GitHub%20Sponsors-30363D?style=flat&logo=GitHub-Sponsors&logoColor=EA4AAA" height="50"></a>

|

||||

<a href="https://ko-fi.com/G2G5IP3CP"><img src="https://img.shields.io/badge/Support_me_on_Ko--fi-FF5E5B?style=flat&logo=ko-fi&logoColor=white" height="50"></a>

|

||||

<a href="https://paypal.me/softfever3d"><img src="https://img.shields.io/badge/PayPal-003087?style=flat&logo=paypal&logoColor=fff" height="50"></a>

|

||||

|

||||

## Some background

|

||||

OrcaSlicer was originally forked from Bambu Studio, it was previously known as BambuStudio-SoftFever.

|

||||

|

||||

[Bambu Studio](https://github.com/bambulab/BambuStudio) is forked from [PrusaSlicer](https://github.com/prusa3d/PrusaSlicer) by Prusa Research, which is from [Slic3r](https://github.com/Slic3r/Slic3r) by Alessandro Ranellucci and the RepRap community.

|

||||

Orca Slicer incorporates a lot of features from [SuperSlicer](https://github.com/supermerill/SuperSlicer) by @supermerill

|

||||

Orca Slicer's logo is designed by community member Justin Levine(@freejstnalxndr)

|

||||

|

||||

Orca Slicer's logo is designed by community member Justin Levine(@freejstnalxndr).

|

||||

|

||||

# License

|

||||

Orca Slicer is licensed under the GNU Affero General Public License, version 3. Orca Slicer is based on Bambu Studio by BambuLab.

|

||||

**Orca Slicer** is licensed under the GNU Affero General Public License, version 3. Orca Slicer is based on Bambu Studio by BambuLab.

|

||||

|

||||

Bambu Studio is licensed under the GNU Affero General Public License, version 3. Bambu Studio is based on PrusaSlicer by PrusaResearch.

|

||||

**Bambu Studio** is licensed under the GNU Affero General Public License, version 3. Bambu Studio is based on PrusaSlicer by PrusaResearch.

|

||||

|

||||

PrusaSlicer is licensed under the GNU Affero General Public License, version 3. PrusaSlicer is owned by Prusa Research. PrusaSlicer is originally based on Slic3r by Alessandro Ranellucci.

|

||||

**PrusaSlicer** is licensed under the GNU Affero General Public License, version 3. PrusaSlicer is owned by Prusa Research. PrusaSlicer is originally based on Slic3r by Alessandro Ranellucci.

|

||||

|

||||

Slic3r is licensed under the GNU Affero General Public License, version 3. Slic3r was created by Alessandro Ranellucci with the help of many other contributors.

|

||||

**Slic3r** is licensed under the GNU Affero General Public License, version 3. Slic3r was created by Alessandro Ranellucci with the help of many other contributors.

|

||||

|

||||

The GNU Affero General Public License, version 3 ensures that if you use any part of this software in any way (even behind a web server), your software must be released under the same license.

|

||||

|

||||

|

|

|

|||

|

|

@ -37,14 +37,6 @@

|

|||

<array>

|

||||

<string>orcaslicer</string>

|

||||

</array>

|

||||

</dict>

|

||||

<dict>

|

||||

<key>CFBundleURLName</key>

|

||||

<string>BambuStudio Downloads</string>

|

||||

<key>CFBundleURLSchemes</key>

|

||||

<array>

|

||||

<string>bambustudioopen</string>

|

||||

</array>

|

||||

</dict>

|

||||

</array>

|

||||

<key>CFBundleDocumentTypes</key>

|

||||

|

|

|

|||

|

|

@ -1,10 +1,14 @@

|

|||

# Auxiliary Fan

|

||||

|

||||

OrcaSlicer use `M106 P2` command to control auxiliary cooling fan.

|

||||

|

||||

If you are using Klipper, you can define a `M106` macro to control the both normal part cooling fan and auxiliary fan and exhaust fan.

|

||||

Below is a reference configuration for Klipper.

|

||||

*Note: Don't forget to change the pin name to the actual pin name you are using in the configuration*

|

||||

If you are using Klipper, you can define a `M106` macro to control the both normal part cooling fan and auxiliary fan and exhaust fan.

|

||||

Below is a reference configuration for Klipper.

|

||||

|

||||

```

|

||||

> [!NOTE]

|

||||

> Don't forget to change the pin name to the actual pin name you are using in the configuration

|

||||

|

||||

```ini

|

||||

# instead of using [fan], we define the default part cooling fan with [fan_generic] here

|

||||

# this is the default part cooling fan

|

||||

[fan_generic fan0]

|

||||

|

|

@ -31,5 +35,4 @@ gcode:

|

|||

{% set fan = 'fan' + (params.P|int if params.P is defined else 0)|string %}

|

||||

{% set speed = (params.S|float / 255 if params.S is defined else 1.0) %}

|

||||

SET_FAN_SPEED FAN={fan} SPEED={speed}

|

||||

|

||||

```

|

||||

|

|

|

|||

|

|

@ -1,343 +0,0 @@

|

|||

- [Flow rate](#flow-rate)

|

||||

- [Pressure Advance](#pressure-advance)

|

||||

- [Line method](#line-method)

|

||||

- [Pattern method](#pattern-method)

|

||||

- [Tower method](#tower-method)

|

||||

- [Temp tower](#temp-tower)

|

||||

- [Retraction test](#retraction-test)

|

||||

- [Orca Tolerance Test](#orca-tolerance-test)

|

||||

- [Advanced Calibration](#advanced-calibration)

|

||||

- [Max Volumetric speed](#max-volumetric-speed)

|

||||

- [Input Shaping](#input-shaping)

|

||||

- [Klipper](#klipper)

|

||||

- [Resonance Compensation](#resonance-compensation)

|

||||

- [Marlin](#marlin)

|

||||

- [ZV Input Shaping](#zv-input-shaping)

|

||||

- [Fixed-Time Motion](#fixed-time-motion)

|

||||

- [Junction Deviation](#junction-deviation)

|

||||

- [VFA](#vfa)

|

||||

|

||||

> [!IMPORTANT]

|

||||

> After completing the calibration process, remember to create a new project in order to exit the calibration mode.

|

||||

|

||||

# Flow rate

|

||||

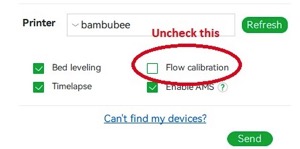

> [!WARNING]

|

||||

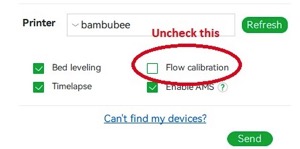

> For Bambulab X1/X1C users, make sure you do not select the 'Flow calibration' option.

|

||||

>

|

||||

>

|

||||

|

||||

> [!IMPORTANT]

|

||||

> PASS 1 and PASS 2 follow the older flow ratio formula `FlowRatio_old*(100 + modifier)/100`. YOLO (Recommended) and YOLO (perfectist version) use a new system that is very simple `FlowRatio_old±modifier`.

|

||||

|

||||

|

||||

|

||||

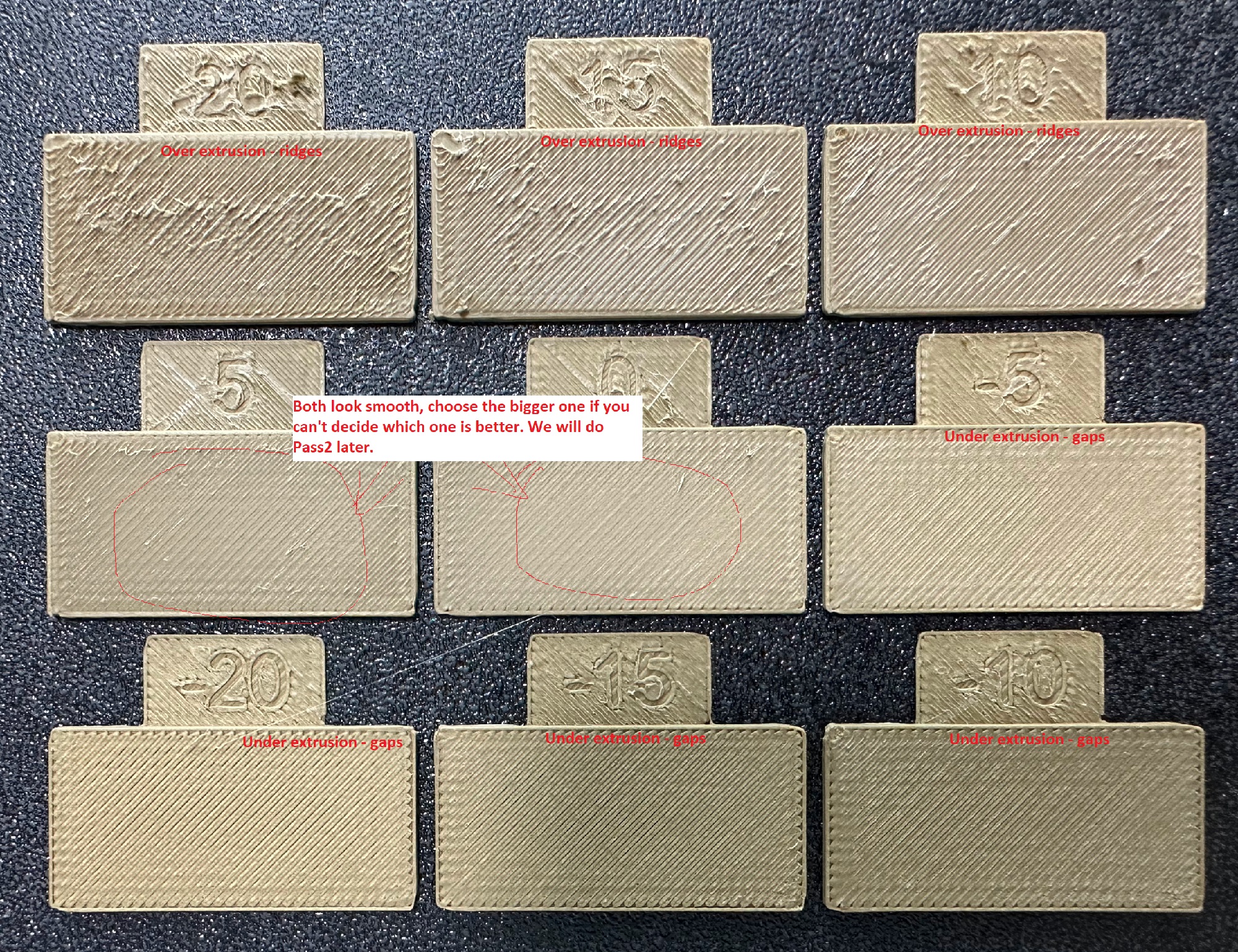

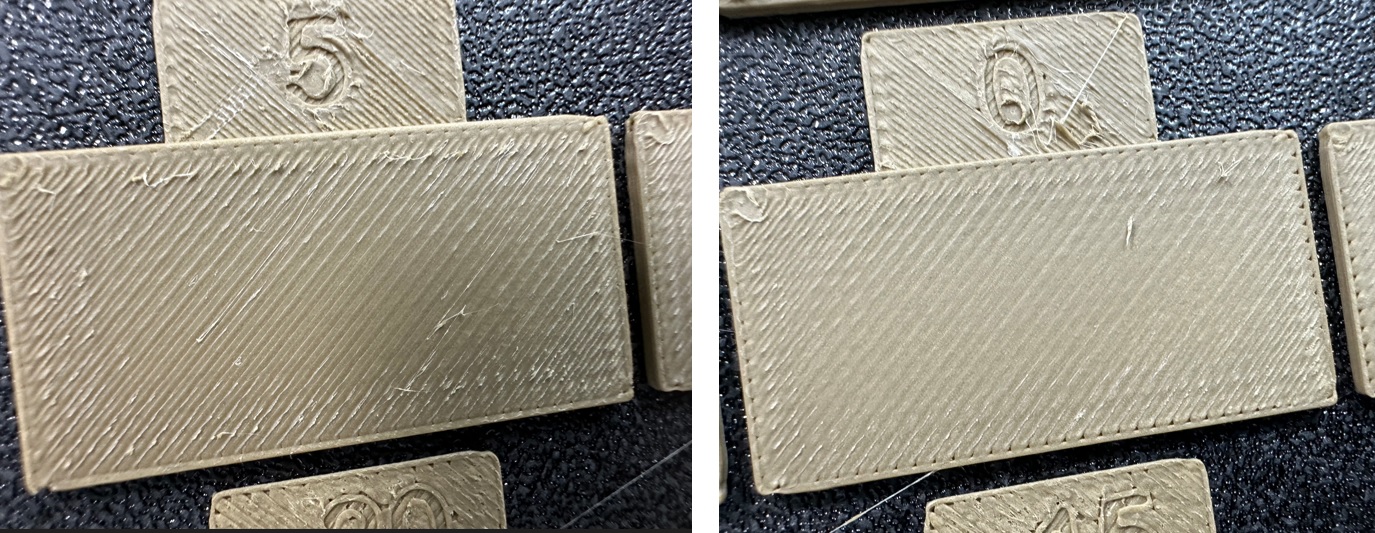

Calibrating the flow rate involves a two-step process.

|

||||

Steps

|

||||

1. Select the printer, filament, and process you would like to use for the test.

|

||||

2. Select `Pass 1` in the `Calibration` menu

|

||||

3. A new project consisting of nine blocks will be created, each with a different flow rate modifier. Slice and print the project.

|

||||

4. Examine the blocks and determine which one has the smoothest top surface.

|

||||

|

||||

|

||||

|

||||

5. Update the flow ratio in the filament settings using the following equation: `FlowRatio_old*(100 + modifier)/100`. If your previous flow ratio was `0.98` and you selected the block with a flow rate modifier of `+5`, the new value should be calculated as follows: `0.98x(100+5)/100 = 1.029`.** Remember** to save the filament profile.

|

||||

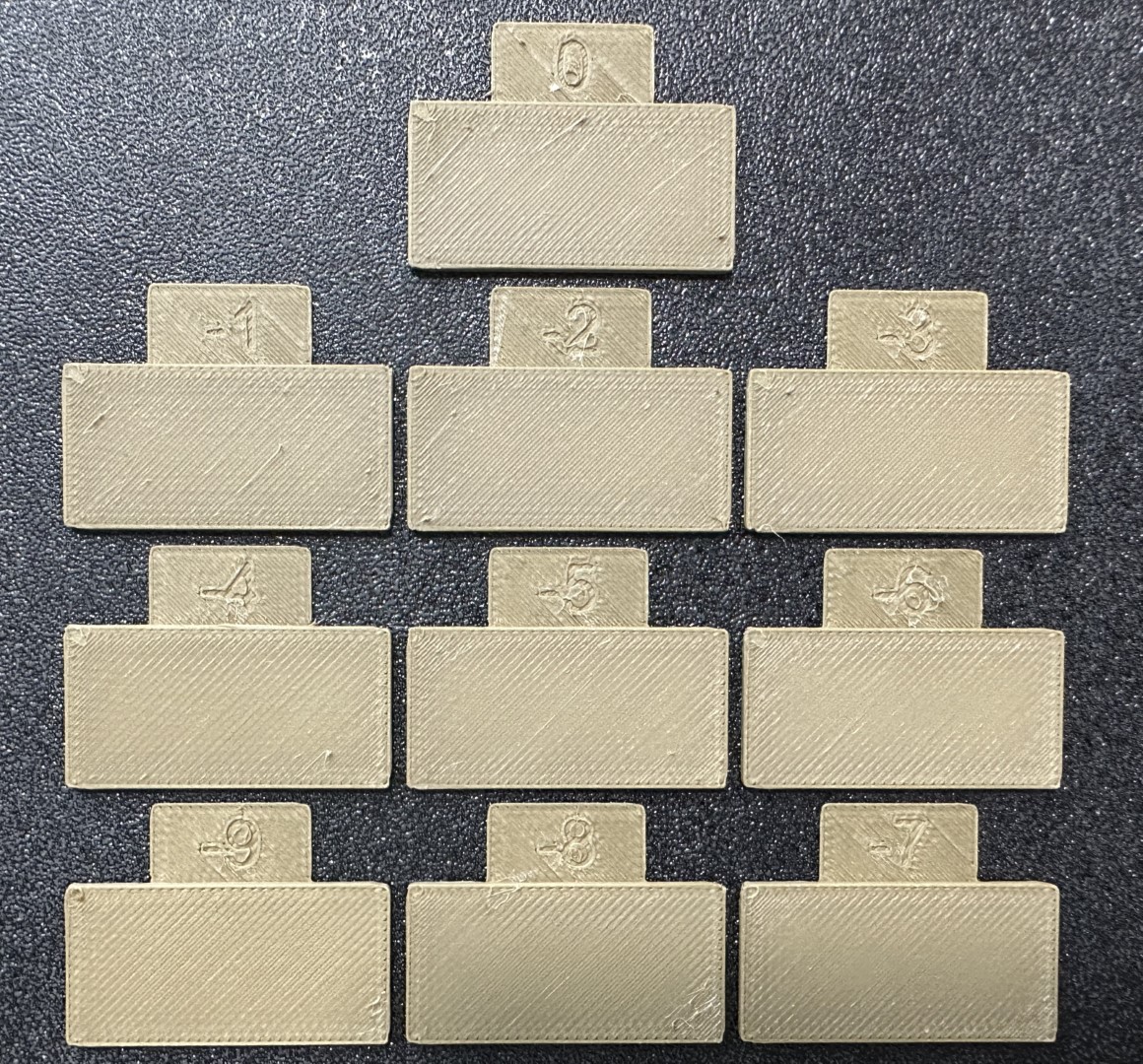

6. Perform the `Pass 2` calibration. This process is similar to `Pass 1`, but a new project with ten blocks will be generated. The flow rate modifiers for this project will range from `-9 to 0`.

|

||||

7. Repeat steps 4. and 5. In this case, if your previous flow ratio was 1.029 and you selected the block with a flow rate modifier of -6, the new value should be calculated as follows: `1.029x(100-6)/100 = 0.96726`. **Remember** to save the filament profile.

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

# Pressure Advance

|

||||

|

||||

Orca Slicer includes three approaches for calibrating the pressure advance value. Each method has its own advantages and disadvantages. It is important to note that each method has two versions: one for a direct drive extruder and one for a Bowden extruder. Make sure to select the appropriate version for your test.

|

||||

|

||||

> [!WARNING]

|

||||

> For Marlin: Linear advance must be enabled in firmware (M900). **Not all printers have it enabled by default.**

|

||||

|

||||

> [!WARNING]

|

||||

> For Bambulab X1/X1C users, make sure you do not select the 'Flow calibration' option when printings.

|

||||

>

|

||||

>

|

||||

|

||||

### Line method

|

||||

|

||||

The line method is quick and straightforward to test. However, its accuracy highly depends on your first layer quality. It is suggested to turn on the bed mesh leveling for this test.

|

||||

Steps:

|

||||

1. Select the printer, filament, and process you would like to use for the test.

|

||||

2. Print the project and check the result. You can select the value of the most even line and update your PA value in the filament settings.

|

||||

3. In this test, a PA value of `0.016` appears to be optimal.

|

||||

|

||||

|

||||

<img width="1003" alt="Screenshot 2022-12-31 at 12 11 10 PM" src="https://user-images.githubusercontent.com/103989404/210124449-dd828da8-a7e4-46b8-9fa2-8bed5605d9f6.png">

|

||||

|

||||

|

||||

|

||||

|

||||

### Pattern method

|

||||

|

||||

The pattern method is adapted from [Andrew Ellis' pattern method generator](https://ellis3dp.com/Pressure_Linear_Advance_Tool/), which was itself derived from the [Marlin pattern method](https://marlinfw.org/tools/lin_advance/k-factor.html) developed by [Sineos](https://github.com/Sineos/k-factorjs).

|

||||

|

||||

[Instructions for using and reading the pattern method](https://ellis3dp.com/Print-Tuning-Guide/articles/pressure_linear_advance/pattern_method.html) are provided in [Ellis' Print Tuning Guide](https://ellis3dp.com/Print-Tuning-Guide/), with only a few Orca Slicer differences to note.

|

||||

|

||||

Test configuration window allow user to generate one or more tests in a single projects. Multiple tests will be placed on each plate with extra plates added if needed.

|

||||

|

||||

1. Single test \

|

||||

|

||||

2. Batch mode testing (multiple tests on a sinle plate) \

|

||||

|

||||

|

||||

Once test generated, one or more small rectangular prisms could be found on the plate, one for each test case. This object serves a few purposes:

|

||||

|

||||

1. The test pattern itself is added in as custom G-Code at each layer, same as you could do by hand actually. The rectangular prism gives us the layers in which to insert that G-Code. This also means that **you'll see the full test pattern when you move to the Preview pane**:

|

||||

|

||||

2. The prism acts as a handle, enabling you to move the test pattern wherever you'd like on the plate by moving the prism

|

||||

3. Each test object is pre-configured with target parameters which are reflected in the objects name. However, test parameters may be adjusted for each prism individually by referring to the object list pane:

|

||||

|

||||

|

||||

Next, Ellis' generator provided the ability to adjust specific printer, filament, and print profile settings. You can make these same changes in Orca Slicer by adjusting the settings in the Prepare pane as you would with any other print. When you initiate the calibration test, Ellis' default settings are applied. A few things to note about these settings:

|

||||

|

||||

1. Ellis specified line widths as a percent of filament diameter. The Orca pattern method does the same to provide its suggested defaults, making use of Ellis' percentages in combination with your specified nozzle diameter

|

||||

2. In terms of line width, the pattern only makes use of the `Default` and `First layer` widths

|

||||

3. In terms of speed, the pattern only uses the `First layer speed -> First layer` and `Other layers speed -> Outer wall` speeds

|

||||

4. The infill pattern beneath the numbers cannot be changed becuase it's not actually an infill pattern pulled from the settings. All of the pattern G-Code is custom written, so that "infill" is, effectively, hand-drawn and so not processed through the usual channels that would enable Orca to recognize it as infill

|

||||

|

||||

### Tower method

|

||||

|

||||

The tower method may take a bit more time to complete, but it does not rely on the quality of the first layer.

|

||||

The PA value for this test will be increased by 0.002 for every 1 mm increase in height. (**NOTE** 0.02 for Bowden)

|

||||

Steps:

|

||||

1. Select the printer, filament, and process you would like to use for the test.

|

||||

2. Examine each corner of the print and mark the height that yields the best overall result.

|

||||

3. I selected a height of 8 mm for this case, so the pressure advance value should be calculated as `PressureAdvanceStart+(PressureAdvanceStep x measured)` example: `0+(0.002 x 8) = 0.016`.

|

||||

|

||||

|

||||

|

||||

|

||||

# Temp tower

|

||||

|

||||

Temp tower is a straightforward test. The temp tower is a vertical tower with multiple blocks, each printed at a different temperature. Once the print is complete, we can examine each block of the tower and determine the optimal temperature for the filament. The optimal temperature is the one that produces the highest quality print with the least amount of issues, such as stringing, layer adhesion, warping (overhang), and bridging.

|

||||

|

||||

|

||||

# Retraction test

|

||||

|

||||

This test generates a retraction tower automatically. The retraction tower is a vertical structure with multiple notches, each printed at a different retraction length. After the print is complete, we can examine each section of the tower to determine the optimal retraction length for the filament. The optimal retraction length is the shortest one that produces the cleanest tower.

|

||||

|

||||

In the dialog, you can select the start and end retraction length, as well as the retraction length increment step. The default values are 0mm for the start retraction length, 2mm for the end retraction length, and 0.1mm for the step. These values are suitable for most direct drive extruders. However, for Bowden extruders, you may want to increase the start and end retraction lengths to 1mm and 6mm, respectively, and set the step to 0.2mm.

|

||||

|

||||

**Note**: When testing filaments such as PLA or ABS that have minimal oozing, the retraction settings can be highly effective. You may find that the retraction tower appears clean right from the start. In such situations, setting the retraction length to 0.2mm - 0.4mm using Orca Slicer should suffice.

|

||||

On the other hand, if there is still a lot of stringing at the top of the tower, it is recommended to dry your filament and ensure that your nozzle is properly installed without any leaks.

|

||||

|

||||

|

||||

# Orca Tolerance Test

|

||||

This tolerance test is specifically designed to assess the dimensional accuracy of your printer and filament. The model comprises a base and a hexagon tester. The base contains six hexagon hole, each with a different tolerance: 0.0mm, 0.05mm, 0.1mm, 0.2mm, 0.3mm, and 0.4mm. The dimensions of the hexagon tester are illustrated in the image.

|

||||

|

||||

|

||||

You can assess the tolerance using either an M6 Allen key or the printed hexagon tester.

|

||||

|

||||

|

||||

|

||||

# Advanced Calibration

|

||||

|

||||

## Max Volumetric speed

|

||||

This is a test designed to calibrate the maximum volumetric speed of the specific filament. The generic or 3rd party filament types may not have the correct volumetric flow rate set in the filament. This test will help you to find the maximum volumetric speed of the filament.

|

||||

|

||||

You will be promted to enter the settings for the test: start volumetric speed, end volumentric speed, and step. It is recommended to use the default values (5mm³/s start, 20mm³/s end, with a step of 0.5), unless you already have an idea of the lower or upper limit for your filament. Select "OK", slice the plate, and send it to the printer.

|

||||

|

||||

Once printed, take note of where the layers begin to fail and where the quality begins to suffer. Pay attention to changes from matte to shiny as well.

|

||||

|

||||

|

||||

|

||||

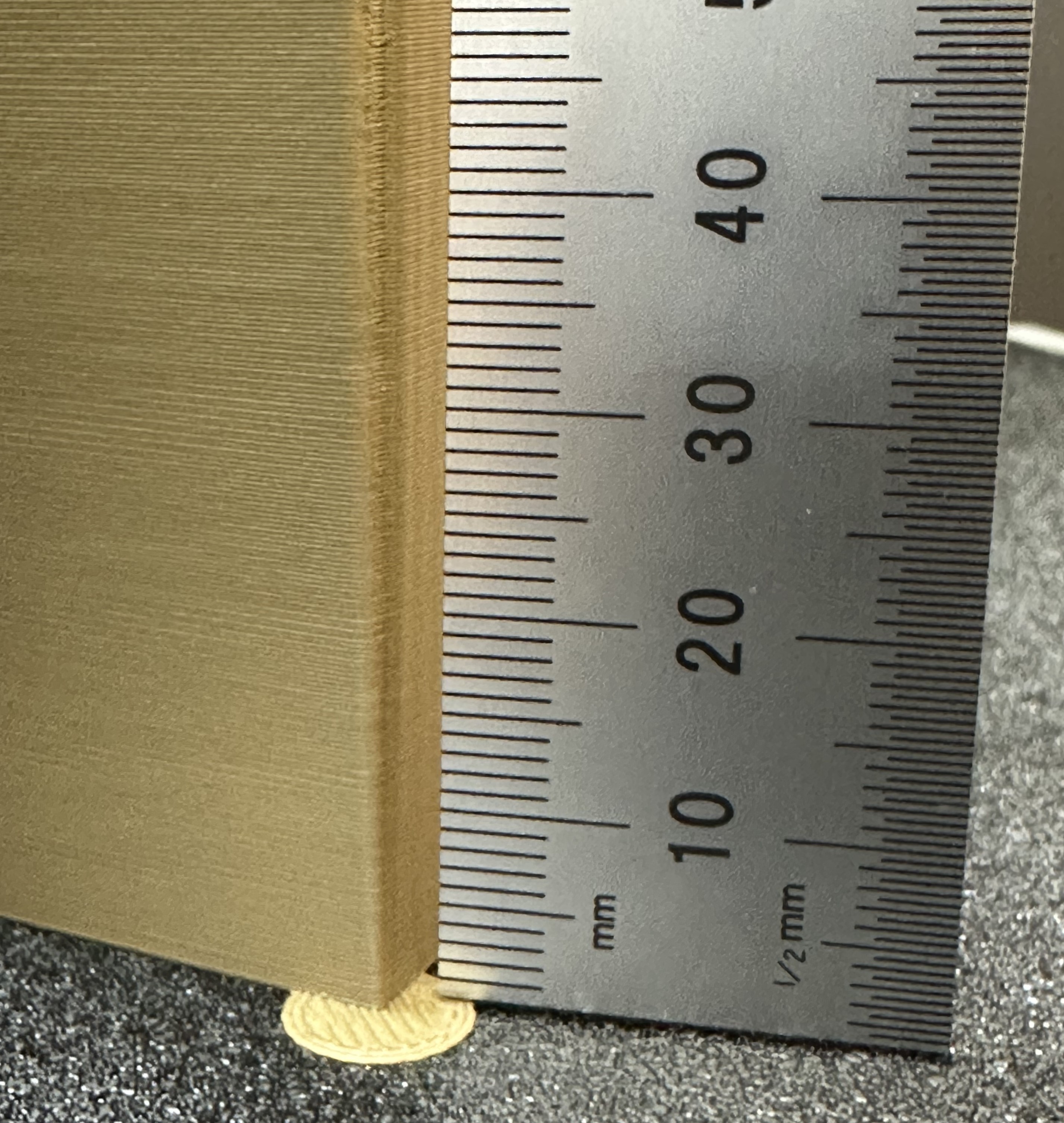

Using calipers or a ruler, measure the height of the print at that point. Use the following calculation to determine the correct max flow value: `start + (height-measured * step)` . For example in the photo below, and using the default setting values, the print quality began to suffer at 19mm measured, so the calculation would be: `5 + (19 * 0.5)` , or `13mm³/s` using the default values. Enter your number into the "Max volumetric speed" value in the filament settings.

|

||||

|

||||

|

||||

|

||||

You can also return to OrcaSlicer in the "Preview" tab, make sure the color scheme "flow" is selected. Scroll down to the layer height that you measured, and click on the toolhead slider. This will indicate the max flow level for your filmanet.

|

||||

|

||||

|

||||

|

||||

> [!NOTE]

|

||||

> You may also choose to conservatively reduce the flow by 5-10% to ensure print quality.

|

||||

|

||||

## Input Shaping

|

||||

|

||||

During high-speed movements, vibrations can cause a phenomenon called "ringing," where periodic ripples appear on the print surface. Input Shaping provides an effective solution by counteracting these vibrations, improving print quality and reducing wear on components without needing to significantly lower print speeds.

|

||||

|

||||

### Klipper

|

||||

|

||||

### Resonance Compensation

|

||||

|

||||

The Klipper Resonance Compensation is a set of Input Shaping modes that can be used to reduce ringing and improve print quality.

|

||||

Ussualy the recommended values modes are ``MZV`` or ``EI`` for Delta printers.

|

||||

|

||||

1. Pre-requisites:

|

||||

1. In OrcaSlicer, set:

|

||||

1. Acceleration high enough to trigger ringing (e.g., 2000 mm/s²).

|

||||

2. Speed high enough to trigger ringing (e.g., 200 mm/s).

|

||||

> [!NOTE]

|

||||

> These settings depend on your printer's motion ability and the filament's max volumetric speed. If you can't reach speeds that cause ringing, try increasing the filament's max volumetric speed (avoid materials below 10 mm³/s).

|

||||

3. Jerk [Klipper Square Corner Velocity](https://www.klipper3d.org/Kinematics.html?h=square+corner+velocity#look-ahead) to 5 or a high value (e.g., 20).

|

||||

2. In printer settigs:

|

||||

1. Set the Shaper Type to ``MZV`` or ``EI``.

|

||||

```

|

||||

SET_INPUT_SHAPER SHAPER_TYPE=MZV

|

||||

```

|

||||

2. Disable [Minimun Cruise Ratio](https://www.klipper3d.org/Kinematics.html#minimum-cruise-ratio) with:

|

||||

```

|

||||

SET_VELOCITY_LIMIT MINIMUM_CRUISE_RATIO=0

|

||||

```

|

||||

3. Use an opaque, high-gloss filament to make the ringing more visible.

|

||||

2. Print the Input Shaping Frequency test with a range of frequencies.

|

||||

|

||||

|

||||

|

||||

1. Measure the X and Y heights and read the frequency set at that point in Orca Slicer.

|

||||

|

||||

|

||||

|

||||

|

||||

2. If not a clear result, you can measure a X and Y min and max acceptable heights and repeat the test with that min and max value.

|

||||

|

||||

**Note**: There is a chance you will need to set higher than 60Hz frequencies. Some printers with very rigid frames and excellent mechanics may exhibit frequencies exceeding 100Hz.

|

||||

3. Print the Damping test setting your X and Y frequency to the value you found in the previous step.

|

||||

|

||||

|

||||

|

||||

1. Measure the X and Y heights and read the damping set at that point in Orca Slicer.

|

||||

|

||||

|

||||

|

||||

|

||||

**Note**: Not all Resonance Compensation modes support damping

|

||||

4. Restore your 3D Printer settings to avoid keep using high acceleration and jerk values.

|

||||

5. Save the settings

|

||||

1. You need to go to the printer settings and set the X and Y frequency and damp to the value you found in the previous step.

|

||||

|

||||

### Marlin

|

||||

|

||||

#### ZV Input Shaping

|

||||

|

||||

ZV Input Shaping introduces an anti-vibration signal into the stepper motion for the X and Y axes. It works by splitting the step count into two halves: the first at half the frequency and the second as an "echo," delayed by half the ringing interval. This simple approach effectively reduces vibrations, improving print quality and allowing for higher speeds.

|

||||

|

||||

1. Pre-requisites:

|

||||

1. In OrcaSlicer, set:

|

||||

1. Acceleration high enough to trigger ringing (e.g., 2000 mm/s²).

|

||||

2. Speed high enough to trigger ringing (e.g., 200 mm/s).

|

||||

> [!NOTE]

|

||||

> These settings depend on your printer's motion ability and the filament's max volumetric speed. If you can't reach speeds that cause ringing, try increasing the filament's max volumetric speed (avoid materials below 10 mm³/s).

|

||||

4. Jerk

|

||||

1. If using [Classic Jerk](https://marlinfw.org/docs/configuration/configuration.html#jerk-) use a high value (e.g., 20).

|

||||

2. If using [Junction Deviation](https://marlinfw.org/docs/features/junction_deviation.html) (new Marlin default mode) this test will use 0.25 (high enough to most printers).

|

||||

2. Use an opaque, high-gloss filament to make the ringing more visible.

|

||||

2. Print the Input Shaping Frequency test with a range of frequencies.

|

||||

|

||||

|

||||

|

||||

1. Measure the X and Y heights and read the frequency set at that point in Orca Slicer.

|

||||

|

||||

|

||||

|

||||

|

||||

2. If not a clear result, you can measure a X and Y min and max acceptable heights and repeat the test with that min and max value.

|

||||

|

||||

**Note**: There is a chance you will need to set higher than 60Hz frequencies. Some printers with very rigid frames and excellent mechanics may exhibit frequencies exceeding 100Hz.

|

||||

3. Print the Damping test setting your X and Y frequency to the value you found in the previous step.

|

||||

|

||||

|

||||

|

||||

1. Measure the X and Y heights and read the damping set at that point in Orca Slicer.

|

||||

|

||||

|

||||

|

||||

|

||||

4. Restore your 3D Printer settings to avoid keep using high acceleration and jerk values.

|

||||

1. Reboot your printer.

|

||||

2. Use the following G-code to restore your printer settings:

|

||||

```gcode

|

||||

M501

|

||||

```

|

||||

5. Save the settings

|

||||

1. You need to go to the printer settings and set the X and Y frequency and damp to the value you found in the previous step.

|

||||

2. Use the following G-code to set the frequency:

|

||||

```gcode

|

||||

M593 X F#Xfrequency D#XDamping

|

||||

M593 Y F#Yfrequency D#YDamping

|

||||

M500

|

||||

```

|

||||

Example

|

||||

```gcode

|

||||

M593 X F37.25 D0.16

|

||||

M593 Y F37.5 D0.06

|

||||

M500

|

||||

```

|

||||

|

||||

#### Fixed-Time Motion

|

||||

|

||||

TODO This calibration test is currently under development. See the [Marlin documentation](https://marlinfw.org/docs/gcode/M493.html) for more information.

|

||||

|

||||

### Junction Deviation

|

||||

|

||||

Junction Deviation is the default method for controlling cornering speed in MarlinFW printers.

|

||||

Higher values result in more aggressive cornering speeds, while lower values produce smoother, more controlled cornering.

|

||||

The default value in Marlin is typically set to 0.08mm, which may be too high for some printers, potentially causing ringing. Consider lowering this value to reduce ringing, but avoid setting it too low, as this could lead to excessively slow cornering speeds.

|

||||

|

||||

1. Pre-requisites:

|

||||

1. Check if your printer has Junction Deviation enabled. You can do this by sending the command `M503` to your printer and looking for the line `Junction deviation: 0.25`.

|

||||

2. In OrcaSlicer, set:

|

||||

1. Acceleration high enough to trigger ringing (e.g., 2000 mm/s²).

|

||||

2. Speed high enough to trigger ringing (e.g., 100 mm/s).

|

||||

3. Use an opaque, high-gloss filament to make the ringing more visible.

|

||||

2. You need to print the Junction Deviation test.

|

||||

|

||||

|

||||

|

||||

1. Measure the X and Y heights and read the frequency set at that point in Orca Slicer.

|

||||

|

||||

|

||||

|

||||

|

||||

2. It’s very likely that you’ll need to set values lower than 0.08 mm, as shown in the previous example. To determine a more accurate maximum JD value, you can print a new calibration tower with a maximum value set at the point where the corners start losing sharpness.

|

||||

3.

|

||||

|

||||

|

||||

4. Measure the X and Y heights and read the frequency set at that point in Orca Slicer.

|

||||

|

||||

|

||||

|

||||

3. Save the settings

|

||||

1. Set your Maximun Junction Deviation value in [Printer settings/Motion ability/Jerk limitation].

|

||||

2. Use the following G-code to set the mm:

|

||||

```gcode

|

||||

M205 J#JunctionDeviationValue

|

||||

M500

|

||||

```

|

||||

Example

|

||||

```gcode

|

||||

M205 J0.012

|

||||

M500

|

||||

```

|

||||

3. Recompile your MarlinFW

|

||||

1. In Configuration.h uncomment and set:

|

||||

```cpp

|

||||

#define JUNCTION_DEVIATION_MM 0.012 // (mm) Distance from real junction edge

|

||||

```

|

||||

2. Check Classic Jerk is disabled (commented).

|

||||

```cpp

|

||||

//#define CLASSIC_JERK

|

||||

```

|

||||

|

||||

## VFA

|

||||

|

||||

Vertical Fine Artifacts (VFA) are small artifacts that can occur on the surface of a 3D print, particularly in areas where there are sharp corners or changes in direction. These artifacts can be caused by a variety of factors, including mechanical vibrations, resonance, and other factors that can affect the quality of the print.

|

||||

Because of the nature of these artifacts the methods to reduce them can be mechanical such as changing motors, belts and pulleys or with advanced calibrations such as Jerk/[Juction Deviation](#junction-deviation) corrections or [Input Shaping](#input-shaping).

|

||||

|

||||

|

||||

***

|

||||

*Credits:*

|

||||

- *The Flowrate test and retraction test is inspired by [SuperSlicer](https://github.com/supermerill/SuperSlicer).*

|

||||

- *The PA Line method is inspired by [K-factor Calibration Pattern](https://marlinfw.org/tools/lin_advance/k-factor.html).*

|

||||

- *The PA Tower method is inspired by [Klipper](https://www.klipper3d.org/Pressure_Advance.html).*

|

||||

- *The temp tower model is remixed from [Smart compact temperature calibration tower](https://www.thingiverse.com/thing:2729076).*

|

||||

- *The max flowrate test was inspired by Stefan (CNC Kitchen), and the model used in the test is a remix of his [Extrusion Test Structure](https://www.printables.com/model/342075-extrusion-test-structure).*

|

||||

- *ZV Input Shaping is inspired by [Marlin Input Shaping](https://marlinfw.org/docs/features/input_shaping.html) and [Ringing Tower 3D STL](https://marlinfw.org/assets/stl/ringing_tower.stl).*

|

||||

- *ChatGPT* ;)

|

||||

|

|

@ -1,23 +1,38 @@

|

|||

OrcaSlicer use `M141/M191` command to control active chamber heater.

|

||||

# Chamber Temperature Control

|

||||

|

||||

If `Activate temperature control` is checked, OrcaSlicer will insert `M191` command at the beginning of the gcode(before `Machine G-code`).

|

||||

|

||||

*Note: If the machine is equipped with an auxiliary fan, OrcaSlicer will automatically activate the fan during the heating period to help circulate air in the chamber.*

|

||||

OrcaSlicer use `M141/M191` command to control active chamber heater.

|

||||

|

||||

If your Filament's `Activate temperature control` and your printer `Support control chamber temperature` option are checked , OrcaSlicer will insert `M191` command at the beginning of the gcode (before `Machine G-code`).

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

There are two chamber temperature variables available that we can use in `Machine G-code` to control the chamber temperature, if you prefer:

|

||||

To access the chamber temperature set in the first filament, use:

|

||||

`M191 S{chamber_temperature[0]}`

|

||||

To use the overall chamber temperature, which is the highest chamber temperature set across all filaments, use:

|

||||

`M191 S{overall_chamber_temperature}`

|

||||

> [!NOTE]

|

||||

> If the machine is equipped with an auxiliary fan, OrcaSlicer will automatically activate the fan during the heating period to help circulate air in the chamber.

|

||||

|

||||

## Using Chamber Temperature Variables in Machine G-code

|

||||

|

||||

--------------------------Klipper--------------------------

|

||||

If you are using Klipper, you can define these macros to control the active chamber heater.

|

||||

Bellow is a reference configuration for Klipper.

|

||||

*Note: Don't forget to change the pin name/values to the actual values you are using in the configuration*

|

||||

You can use chamber temperature variables in your `Machine G-code` to control the chamber temperature manually, if desired:

|

||||

|

||||

```

|

||||

- To set the chamber temperature to the value specified for the first filament:

|

||||

```gcode

|

||||

M191 S{chamber_temperature[0]}

|

||||

```

|

||||

- To set the chamber temperature to the highest value specified across all filaments:

|

||||

```gcode

|

||||

M191 S{overall_chamber_temperature}

|

||||

```

|

||||

|

||||

## Klipper

|

||||

|

||||

If you are using Klipper, you can define these macros to control the active chamber heater.

|

||||

Bellow is a reference configuration for Klipper.

|

||||

|

||||

> [!IMPORTANT]

|

||||

> Don't forget to change the pin name/values to the actual values you are using in the configuration.

|

||||

|

||||

```gcode

|

||||

[heater_generic chamber_heater]

|

||||

heater_pin:PB10

|

||||

max_power:1.0

|

||||

|

|

@ -25,7 +40,7 @@ max_power:1.0

|

|||

sensor_type:NTC 100K MGB18-104F39050L32

|

||||

sensor_pin:PA1

|

||||

control = pid

|

||||

pid_Kp = 63.418

|

||||

pid_Kp = 63.418

|

||||

pid_ki = 0.960

|

||||

pid_kd = 1244.716

|

||||

min_temp:0

|

||||

|

|

@ -48,5 +63,4 @@ gcode:

|

|||

TEMPERATURE_WAIT SENSOR="heater_generic chamber_heater" MINIMUM={s-1} MAXIMUM={s+1}

|

||||

M117 Chamber at target temperature

|

||||

{% endif %}

|

||||

|

||||

```

|

||||

```

|

||||

|

|

|

|||

48

doc/Home.md

|

|

@ -1,40 +1,68 @@

|

|||

# Welcome to the OrcaSlicer WIKI!

|

||||

|

||||

Orca slicer is a powerful open source slicer for FFF (FDM) 3D Printers. This wiki page aims to provide an detailed explanation of the slicer settings, how to get the most out of them as well as how to calibrate and setup your printer.

|

||||

Orca slicer is a powerful open source slicer for FFF (FDM) 3D Printers. This wiki page aims to provide an detailed explanation of the slicer settings, how to get the most out of them as well as how to calibrate and setup your printer.

|

||||

|

||||

The Wiki is work in progress so bear with us while we get it up and running!

|

||||

- [Print Settings, Tips and Tricks](#print-settings-tips-and-tricks)

|

||||

- [Quality Settings](#quality-settings)

|

||||

- [Speed Settings](#speed-settings)

|

||||

- [Multi material](#multi-material)

|

||||

- [Printer Settings](#printer-settings)

|

||||

- [Printer Calibration](#printer-calibration)

|

||||

- [Developer Section](#developer-section)

|

||||

|

||||

> [!NOTE]

|

||||

> The Wiki is **Work In Progress** so bear with us while we get it up and running!

|

||||

|

||||

## Print Settings, Tips and Tricks

|

||||

|

||||

## Print Settings, Tips and Tricks (Work In Progress)

|

||||

The below sections provide a detailed settings explanation as well as tips and tricks in setting these for optimal print results.

|

||||

|

||||

### Quality Settings

|

||||

|

||||

- [Layer Height Settings](quality_settings_layer_height)

|

||||

- [Line Width Settings](quality_settings_line_width)

|

||||

- [Seam Settings](quality_settings_seam)

|

||||

- [Precise wall](Precise-wall)

|

||||

- [Precise Z height](precise-z-height)

|

||||

- [STL Transformation](stl-transformation)

|

||||

|

||||

### Speed Settings

|

||||

|

||||

- [Extrusion rate smoothing](extrusion-rate-smoothing)

|

||||

|

||||

### Multi material

|

||||

|

||||

- [Single Extruder Multimaterial](semm)

|

||||

|

||||

### Printer Settings:

|

||||

### Printer Settings

|

||||

|

||||

- [Air filtration/Exhaust fan handling](air-filtration)

|

||||

- [Auxiliary fan handling](Auxiliary-fan)

|

||||

- [Chamber temperature control](chamber-temperature)

|

||||

- [Adaptive Bed Mesh](adaptive-bed-mesh)

|

||||

- [Using different bed types in Orca](bed-types)

|

||||

- [Pellet Printers (pellet flow coefficient)](pellet-flow-coefficient)

|

||||

- [Fill Patterns](fill-patterns)

|

||||

|

||||

## Printer Calibration

|

||||

The guide below takes you through the key calibration tests in Orca - flow rate, pressure advance, print temperature, retraction, tolerances and maximum volumetric speed

|

||||

- [Calibration Guide](./Calibration)

|

||||

- [Adaptive Pressure Advance Guide](adaptive-pressure-advance)

|

||||

|

||||

The [Calibration Guide](Calibration) outlines Orca’s key calibration tests and their suggested order of execution.

|

||||

|

||||

- [Temperature](temp-calib)

|

||||

- [Flow Rate](flow-rate-calib)

|

||||

- [Pressure Advance](pressure-advance-calib)

|

||||

- [Adaptive Pressure Advance Guide](adaptive-pressure-advance-calib)

|

||||

- [Retraction](retraction-calib)

|

||||

- [Tolerance](tolerance-calib)

|

||||

- Advanced:

|

||||

- [Volumetric Speed](volumetric-speed-calib)

|

||||

- [Cornering (Jerk & Junction Deviation)](cornering-calib)

|

||||

- [Input Shaping](input-shaping-calib)

|

||||

|

||||

## Developer Section

|

||||

- [How to build Orca Slicer](./How-to-build)

|

||||

|

||||

- [How to build Orca Slicer](How-to-build)

|

||||

- [Localization and translation guide](Localization_guide)

|

||||

- [Developer Reference](https://github.com/SoftFever/OrcaSlicer/blob/main/doc/developer-reference/Home.md)

|

||||

- [How to create profiles](./How-to-create-profiles)

|

||||

- [Developer Reference](Developers-Home)

|

||||

- [How to create profiles](How-to-create-profiles)

|

||||

- [How to contribute to the wiki](How-to-wiki)

|

||||

|

|

|

|||

|

|

@ -1,11 +1,193 @@

|

|||

# How to compile

|

||||

- Windows 64-bit

|

||||

- Tools needed: Visual Studio 2019, Cmake, git, Strawberry Perl.

|

||||

- Run `build_release.bat` in `x64 Native Tools Command Prompt for VS 2019`

|

||||

# How to Build

|

||||

|

||||

- Mac 64-bit

|

||||

- Tools needed: Xcode, Cmake, git, gettext

|

||||

- run `build_release_macos.sh`

|

||||

## Windows 64-bit

|

||||

|

||||

- Ubuntu

|

||||

- run `BuildLinux.sh -udisr`

|

||||

This guide is for building your Visual Studio 2022 solution for OrcaSlicer on Windows 64-bit.

|

||||

|

||||

### Tools Required

|

||||

|

||||

- [Visual Studio 2022](https://visualstudio.microsoft.com/vs/) or Visual Studio 2019

|

||||

```shell

|

||||

winget install --id=Microsoft.VisualStudio.2022.Professional -e

|

||||

```

|

||||

- [CMake (version 3.31)](https://cmake.org/) — **⚠️ version 3.31.x is mandatory**

|

||||

```shell

|

||||

winget install --id=Kitware.CMake -v "3.31.6" -e

|

||||

```

|

||||

- [Strawberry Perl](https://strawberryperl.com/)

|

||||

```shell

|

||||

winget install --id=StrawberryPerl.StrawberryPerl -e

|

||||

```

|

||||

- [Git](https://git-scm.com/)

|

||||

```shell

|

||||

winget install --id=Git.Git -e

|

||||

```

|

||||

- [git-lfs](https://git-lfs.com/)

|

||||

```shell

|

||||

winget install --id=GitHub.GitLFS -e

|

||||

```

|

||||

|

||||

> [!TIP]

|

||||

> GitHub Desktop (optional): A GUI for Git and Git LFS, which already includes both tools.

|

||||

> ```shell

|

||||

> winget install --id=GitHub.GitHubDesktop -e

|

||||

> ```

|

||||

|

||||

### Instructions

|

||||

|

||||

1. Clone the repository:

|

||||

- If using GitHub Desktop clone the repository from the GUI.

|

||||

- If using the command line:

|

||||

1. Clone the repository:

|

||||

```shell

|

||||

git clone https://github.com/SoftFever/OrcaSlicer

|

||||

```

|

||||

2. Run lfs to download tools on Windows:

|

||||

```shell

|

||||

git lfs pull

|

||||

```

|

||||

2. Open the appropriate command prompt:

|

||||

- For Visual Studio 2019:

|

||||

Open **x64 Native Tools Command Prompt for VS 2019** and run:

|

||||

```shell

|

||||

build_release.bat

|

||||

```

|

||||

- For Visual Studio 2022:

|

||||

Open **x64 Native Tools Command Prompt for VS 2022** and run:

|

||||

```shell

|

||||

build_release_vs2022.bat

|

||||

```

|

||||

3. If successful, you will find the VS 2022 solution file in:

|

||||

```shell

|

||||

build\OrcaSlicer.sln

|

||||

```

|

||||

|

||||

> [!IMPORTANT]

|

||||

> Make sure that CMake version 3.31.x is actually being used. Run `cmake --version` and verify it returns a **3.31.x** version.

|

||||

> If you see an older version (e.g. 3.29), it's likely due to another copy in your system's PATH (e.g. from Strawberry Perl).

|

||||

> You can run where cmake to check the active paths and rearrange your System Environment Variables > PATH, ensuring the correct CMake (e.g. C:\Program Files\CMake\bin) appears before others like C:\Strawberry\c\bin.

|

||||

|

||||

> [!NOTE]

|

||||

> If the build fails, try deleting the `build/` and `deps/build/` directories to clear any cached build data. Rebuilding after a clean-up is usually sufficient to resolve most issues.

|

||||

|

||||

## macOS 64-bit

|

||||

|

||||

### Tools Required

|

||||

|

||||

- Xcode

|

||||

- CMake (version 3.31.x is mandatory)

|

||||

- Git

|

||||

- gettext

|

||||

- libtool

|

||||

- automake

|

||||

- autoconf

|

||||

- texinfo

|

||||

|

||||

> [!TIP]

|

||||

> You can install most of them by running:

|

||||

> ```shell

|

||||

> brew install gettext libtool automake autoconf texinfo

|

||||

> ```

|

||||

|

||||

Homebrew currently only offers the latest version of CMake (e.g. **4.X**), which is not compatible. To install the required version **3.31.X**, follow these steps:

|

||||

|

||||

1. Download CMake **3.31.7** from: [https://cmake.org/download/](https://cmake.org/download/)

|

||||

2. Install the application (drag it to `/Applications`).

|

||||

3. Add the following line to your shell configuration file (`~/.zshrc` or `~/.bash_profile`):

|

||||

|

||||

```sh

|

||||

export PATH="/Applications/CMake.app/Contents/bin:$PATH"

|

||||

```

|

||||

|

||||

4. Restart the terminal and check the version:

|

||||

|

||||

```sh

|

||||

cmake --version

|

||||

```

|

||||

|

||||

5. Make sure it reports a **3.31.x** version.

|

||||

|

||||

> [!IMPORTANT]

|

||||

> If you've recently upgraded Xcode, be sure to open Xcode at least once and install the required macOS build support.

|

||||

|

||||

### Instructions

|

||||

|

||||

1. Clone the repository:

|

||||

```shell

|

||||

git clone https://github.com/SoftFever/OrcaSlicer

|

||||

cd OrcaSlicer

|

||||

```

|

||||

2. Build the application:

|

||||

```shell

|

||||

./build_release_macos.sh

|

||||

```

|

||||

3. Open the application:

|

||||

```shell

|

||||

open build/arm64/OrcaSlicer/OrcaSlicer.app

|

||||

```

|

||||

|

||||

### Debugging in Xcode

|

||||

|

||||

To build and debug directly in Xcode:

|

||||

|

||||

1. Open the Xcode project:

|

||||

```shell

|

||||

open build/arm64/OrcaSlicer.xcodeproj

|

||||

```

|

||||

2. In the menu bar:

|

||||

- **Product > Scheme > OrcaSlicer**

|

||||

- **Product > Scheme > Edit Scheme...**

|

||||

- Under **Run > Info**, set **Build Configuration** to `RelWithDebInfo`

|

||||

- Under **Run > Options**, uncheck **Allow debugging when browsing versions**

|

||||

- **Product > Run**

|

||||

|

||||

## Linux

|

||||

|

||||

### Using Docker (Recommended)

|

||||

|

||||

#### Dependencies

|

||||

|

||||

- Docker

|

||||

- Git

|

||||

|

||||

#### Instructions

|

||||

|

||||

```shell

|

||||

git clone https://github.com/SoftFever/OrcaSlicer && cd OrcaSlicer && ./DockerBuild.sh && ./DockerRun.sh

|

||||

```

|

||||

|

||||

> [!NOTE]

|

||||

> To troubleshoot common Docker-related errors, refer to the comments in

|

||||

> ```shell

|

||||

> DockerRun.sh

|

||||

> ```

|

||||

|

||||

## Ubuntu

|

||||

|

||||

### Dependencies

|

||||

|

||||

All required dependencies will be installed automatically by the provided shell script, including:

|

||||

|

||||

- libmspack-dev

|

||||

- libgstreamerd-3-dev

|

||||

- libsecret-1-dev

|

||||

- libwebkit2gtk-4.0-dev

|

||||

- libosmesa6-dev

|

||||

- libssl-dev

|

||||

- libcurl4-openssl-dev

|

||||

- eglexternalplatform-dev

|

||||

- libudev-dev

|

||||

- libdbus-1-dev

|

||||

- extra-cmake-modules

|

||||

- libgtk2.0-dev

|

||||

- libglew-dev

|

||||

- cmake

|

||||

- git

|

||||

- texinfo

|

||||

|

||||

### Instructions

|

||||

|

||||

```shell

|

||||

sudo ./BuildLinux.sh -u # Install dependencies

|

||||

./BuildLinux.sh -dsi # Build OrcaSlicer

|

||||

```

|

||||

|

|

|

|||

|

|

@ -1,10 +1,13 @@

|

|||

# Guide: Develop Profiles for OrcaSlicer

|

||||

|

||||

## Introduction

|

||||

|

||||

This guide will help you develop profiles for OrcaSlicer.

|

||||

|

||||

## High-level Overview

|

||||

|

||||

OrcaSlicer uses JSON files to store profiles. There are four types of profiles:

|

||||

|

||||

1. Printer model (type `machine_model`). Example: `Orca 3D Fuse1.json`

|

||||

2. Printer variant (type `machine`). Example: `Orca 3D Fuse1 0.2 nozzle.json`

|

||||

3. Filament (type `filament`). Example: `Generic PLA @Orca 3D Fuse1@.json`

|

||||

|

|

@ -15,6 +18,7 @@ Additionally, there is an overall meta file for each vendor (`Orca 3D.json`).

|

|||

For easier understanding, let's consider a scenario with a printer manufacturer called `Orca 3D`. The manufacturer offers one printer model called `Fuse 1`, which supports 0.2/0.4/0.6/0.8mm nozzles and common market filaments.

|

||||

|

||||

In this case:

|

||||

|

||||

- Vendor profile: `Orca 3D`

|

||||

- Printer profile: `Orca 3D Fuse1`

|

||||

- Printer variant profile: `Orca 3D Fuse1 0.4 nozzle`

|

||||

|

|

@ -23,39 +27,54 @@ In this case:

|

|||

|

||||

The profile name should be same as the filename without the `.json` extension in principal.

|

||||

Naming conventions:

|

||||

|

||||

1. Vendor profile: `vendor_name.json`

|

||||

2. Printer profile: `vendor_name` + `printer_name` + `.json`

|

||||

3. Printer variant profile: `vendor_name` + `printer_variant_name` + `.json` (where `printer_variant_name` typically includes `printer_name` + `nozzle_diameter`)

|

||||

4. Filament profile: `filament_vendor_name` + `filament_name` + " @" + `vendor_name` + `printer_name`/`printer_variant_name` + `.json`

|

||||

5. Process profile: `layer_height` + `preset_name` + " @" + `vendor_name` + `printer_name`/`printer_variant_name` + `.json` (`preset_name` typically includes "standard," "fine," "fast," "draft," etc.)

|

||||

|

||||

## File Structure and Templates

|

||||

|

||||

A typical file structure for a vendor:

|

||||

```

|

||||

Profiles should be structured in the following way under the OrcaSlicer installation directory:

|

||||

|

||||

```plaintext

|

||||

resources\profiles\

|

||||

- Orca 3D.json

|

||||

- Orca 3D\

|

||||

- machine\

|

||||

- Orca 3D Fuse1.json

|

||||

- Orca 3D Fuse1 0.2 nozzle.json

|

||||

- Orca 3D Fuse1 0.4 nozzle.json

|

||||

- process\

|

||||

- 0.10mm Standard @Orca 3D Fuse1 0.2.json

|