mirror of

https://github.com/SoftFever/OrcaSlicer.git

synced 2025-08-05 21:14:01 -06:00

Wiki + Readme: MD security and improvements (#9807)

* Wiki + Readme: MD, security and improvements Standardized MD GitHub Wiki format Removed outdated and malicious links Modularized calibrations Suggested calibration order added Minor bug fixes Image improvements and corrections Added winget commands Completed previous WIPs Added new WIPs Removed obsolete references Visual Changes Co-Authored-By: Noisyfox <timemanager.rick@gmail.com> Co-Authored-By: dewi-ny-je <2866139+dewi-ny-je@users.noreply.github.com> Co-Authored-By: Nico Domino <7415984+ndom91@users.noreply.github.com> Co-Authored-By: Martin Ulmschneider <7497782+mulmschneider@users.noreply.github.com> Co-Authored-By: Rodrigo <162915171+RF47@users.noreply.github.com> * MD Indentation + images update --------- Co-authored-by: Noisyfox <timemanager.rick@gmail.com> Co-authored-by: dewi-ny-je <2866139+dewi-ny-je@users.noreply.github.com> Co-authored-by: Nico Domino <7415984+ndom91@users.noreply.github.com> Co-authored-by: Martin Ulmschneider <7497782+mulmschneider@users.noreply.github.com> Co-authored-by: Rodrigo <162915171+RF47@users.noreply.github.com>

This commit is contained in:

parent

0242e9462b

commit

4e59b0abc6

44 changed files with 1192 additions and 690 deletions

65

doc/print_settings/calibration/Calibration.md

Normal file

65

doc/print_settings/calibration/Calibration.md

Normal file

|

|

@ -0,0 +1,65 @@

|

|||

# Calibration Guide

|

||||

|

||||

This guide offers a structured and comprehensive overview of the calibration process for Orca Slicer.

|

||||

|

||||

It covers key aspects such as flow rate, pressure advance, temperature towers, retraction tests, and advanced calibration techniques. Each section includes step-by-step instructions and visuals to help you better understand and carry out each calibration effectively.

|

||||

|

||||

To access the calibration features, you can find them in the **Calibration** section of the Orca Slicer interface.

|

||||

|

||||

|

||||

|

||||

> [!IMPORTANT]

|

||||

> After completing the calibration process, remember to create a new project in order to exit the calibration mode.

|

||||

|

||||

The recommended order for calibration is as follows:

|

||||

|

||||

1. **[Temperature](temp-calib.md)**: Start by calibrating the temperature of the nozzle and the bed. This is crucial as it affects the viscosity of the filament, which in turn influences how well it flows through the nozzle and adheres to the print bed.

|

||||

|

||||

<img src="https://user-images.githubusercontent.com/103989404/221344534-40e1a629-450c-4ad5-a051-8e240e261a51.jpeg" alt="temp_tower" height="200">

|

||||

|

||||

2. **[Flow](flow-rate-calib.md)**: Calibrate the flow rate to ensure that the correct amount of filament is being extruded. This is important for achieving accurate dimensions and good layer adhesion.

|

||||

|

||||

<img src="https://user-images.githubusercontent.com/103989404/210138585-98821729-b19e-4452-a08d-697f147d36f0.jpg" alt="Flow" height="200">

|

||||

|

||||

3. **[Pressure Advance](pressure-advance-calib.md)**: Calibrate the pressure advance settings to improve print quality and reduce artifacts caused by pressure fluctuations in the nozzle.

|

||||

|

||||

- **[Adaptative Pressure Advance](adaptive-pressure-advance-calib.md)**: This is an advanced calibration technique that can be used to further optimize the pressure advance settings for different print speeds and geometries.

|

||||

|

||||

<img src="https://user-images.githubusercontent.com/103989404/210140231-e886b98d-280a-4464-9781-c74ed9b7d44e.jpg" alt="Pressure_Advance" height="200">

|

||||

|

||||

4. **[Retraction](retraction-calib.md)**: Calibrate the retraction settings to minimize stringing and improve print quality. Doing this after Flow and

|

||||

|

||||

<img src="../../images/retraction_test_print.jpg" alt="Retraction" height="200">

|

||||

|

||||

5. **[Tolerance](tolerance-calib.md)**: Calibrate the tolerances of your printer to ensure that it can accurately reproduce the dimensions of the model being printed. This is important for achieving a good fit between parts and for ensuring that the final print meets the desired specifications.

|

||||

|

||||

<img src="../../images/Tolerance/OrcaToleranceTes_m6.jpg" alt="Tolerance" height="200">

|

||||

|

||||

6. **[Max Volumetric Speed](volumetric-speed-calib.md)**: Calibrate the maximum volumetric speed of the filament. This is important for ensuring that the printer can handle the flow rate of the filament without causing issues such as under-extrusion or over-extrusion.

|

||||

|

||||

<img src="../../images/vmf_measurement_point.jpg" alt="Max_Volumetric_Speed" height="200">

|

||||

|

||||

7. **[Cornering](cornering-calib.md)**: Calibrate the Jerk/Junction Deviation settings to improve print quality and reduce artifacts caused by sharp corners and changes in direction.

|

||||

|

||||

<img src="../../images/JunctionDeviation/jd_second_print_measure.jpg" alt="Cornering" height="200">

|

||||

|

||||

8. **[Input Shaping](input-shaping-calib.md)**: This is an advanced calibration technique that can be used to reduce ringing and improve print quality by compensating for mechanical vibrations in the printer.

|

||||

|

||||

<img src="../../images/InputShaping/IS_damp_marlin_print_measure.jpg" alt="Input_Shaping" height="200">

|

||||

|

||||

### VFA

|

||||

|

||||

Vertical Fine Artifacts (VFA) are small artifacts that can occur on the surface of a 3D print, particularly in areas where there are sharp corners or changes in direction. These artifacts can be caused by a variety of factors, including mechanical vibrations, resonance, and other factors that can affect the quality of the print.

|

||||

Because of the nature of these artifacts the methods to reduce them can be mechanical such as changing motors, belts and pulleys or with advanced calibrations such as Jerk/[Juction Deviation](#junction-deviation) corrections or [Input Shaping](#input-shaping).

|

||||

|

||||

---

|

||||

|

||||

_Credits:_

|

||||

|

||||

- _The Flowrate test and retraction test is inspired by [SuperSlicer](https://github.com/supermerill/SuperSlicer)._

|

||||

- _The PA Line method is inspired by [K-factor Calibration Pattern](https://marlinfw.org/tools/lin_advance/k-factor.html)._

|

||||

- _The PA Tower method is inspired by [Klipper](https://www.klipper3d.org/Pressure_Advance.html)._

|

||||

- _The temp tower model is remixed from [Smart compact temperature calibration tower](https://www.thingiverse.com/thing:2729076)._

|

||||

- _The max flowrate test was inspired by Stefan (CNC Kitchen), and the model used in the test is a remix of his [Extrusion Test Structure](https://www.printables.com/model/342075-extrusion-test-structure)._

|

||||

- _ZV Input Shaping is inspired by [Marlin Input Shaping](https://marlinfw.org/docs/features/input_shaping.html) and [Ringing Tower 3D STL](https://marlinfw.org/assets/stl/ringing_tower.stl)._

|

||||

- _ChatGPT_ ;)

|

||||

|

|

@ -0,0 +1,201 @@

|

|||

# Adaptive Pressure Advance

|

||||

|

||||

This feature aims to dynamically adjust the printer’s pressure advance to better match the conditions the toolhead is facing during a print. Specifically, to more closely align to the ideal values as flow rate, acceleration, and bridges are encountered.

|

||||

This wiki page aims to explain how this feature works, the prerequisites required to get the most out of it as well as how to calibrate it and set it up.

|

||||

|

||||

## Settings Overview

|

||||

|

||||

This feature introduces the below options under the filament settings:

|

||||

|

||||

1. **Enable adaptive pressure advance:** This is the on/off setting switch for adaptive pressure advance.

|

||||

2. **Enable adaptive pressure advance for overhangs:** Enable adaptive PA for overhangs as well as when flow changes within the same feature. This is an experimental option because if the PA profile is not set accurately, it will cause uniformity issues on the external surfaces before and after overhangs. It is recommended to start with this option switched off and enable it after the core adaptive pressure advance feature is calibrated correctly.

|

||||

3. **Pressure advance for bridges:** Sets the desired pressure advance value for bridges. Set it to 0 to disable this feature. Experiments have shown that a lower PA value when printing bridges helps reduce the appearance of slight under extrusion immediately after a bridge, which is caused by the pressure drop in the nozzle when printing in the air. Therefore, a lower pressure advance value helps counteract this. A good starting point is approximately half your usual PA value.

|

||||

4. **Adaptive pressure advance measurements:** This field contains the calibration values used to generate the pressure advance profile for the nozzle/printer. Input sets of pressure advance (PA) values and the corresponding volumetric flow speeds and accelerations they were measured at, separated by a comma. Add one set of values per line. More information on how to calibrate the model follows in the sections below.

|

||||

5. **Pressure advance:** The old field is still needed and is required to be populated with a PA value. A “good enough” median PA value should be entered here, as this will act as a fallback value when performing tool changes, printing a purge/wipe tower for multi-color prints as well as a fallback in case the model fails to identify an appropriate value (unlikely but it’s the ultimate backstop).

|

||||

|

||||

<img width="452" alt="Adaptive PA settings" src="https://github.com/user-attachments/assets/68c46885-54c7-4123-afa0-762d3995185f">

|

||||

|

||||

## Pre-Requisites

|

||||

|

||||

This feature has been tested with Klipper-based printers. While it may work with Marlin or Bambu lab printers, it is currently untested with them. It shouldn’t adversely affect the machine; however, the quality results from enabling it are not validated.

|

||||

|

||||

**Older versions of Klipper used to stutter when pressure advance was changed while the toolhead was in motion. This has been fixed with the latest Klipper firmware releases. Therefore, make sure your Klipper installation is updated to the latest version before enabling this feature, in order to avoid any adverse quality impacts.**

|

||||

|

||||

Klipper firmware released after July 11th, 2024 (version greater than approximately v0.12.0-267) contains the above fix and is compatible with adaptive pressure advance. If you are upgrading from an older version, make sure you update both your Klipper installation as well as reflash the printer MCU’s (main board and toolhead board if present).

|

||||

|

||||

## Use case (what to expect)

|

||||

|

||||

Following experimentation, it has been noticed that the optimal pressure advance value is less:

|

||||

|

||||

1. The faster you print (hence the higher the volumetric flow rate requested from the toolhead).

|

||||

2. The larger the layer height (hence the higher the volumetric flow rate requested from the toolhead).

|

||||

3. The higher the print acceleration is.

|

||||

|

||||

What this means is that we never get ideal PA values for each print feature, especially when they vary drastically in speed and acceleration. We can tune PA for a faster print speed (flow) but compromise on corner sharpness for slower speeds or tune PA for corner sharpness and deal with slight corner-perimeter separation in faster speeds. The same goes for accelerations as well as different layer heights.

|

||||

|

||||

This compromise usually means that we settle for tuning an "in-between" PA value between slower external features and faster internal features so we don't get gaps, but also not get too much bulging in external perimeters.

|

||||

|

||||

**However, what this also means is that if you are printing with a single layer height, single speed, and acceleration, there is no need to enable this feature.**

|

||||

|

||||

Adaptive pressure advance aims to address this limitation by implementing a completely different method of setting pressure advance. **Following a set of PA calibration tests done at different flow rates (speeds and layer heights) and accelerations, a pressure advance model is calculated by the slicer.** Then that model is used to emit the best fit PA for any arbitrary feature flow rate (speed) and acceleration used in the print process.

|

||||

|

||||

In addition, it means that you only need to tune this feature once and print across different layer heights with good PA performance.

|

||||

|

||||

Finally, if during calibration you notice that there is little to no variance between the PA tests, this feature is redundant for you. **From experiments, high flow nozzles fitted on high-speed core XY printers appear to benefit the most from this feature as they print with a larger range of flow rates and at a larger range of accelerations.**

|

||||

|

||||

### Expected results:

|

||||

|

||||

With this feature enabled there should be absolutely no bulge in the corners, just the smooth rounding caused by the square corner velocity of your printer.

|

||||

|

||||

In addition, seams should appear smooth with no bulging or under extrusion.

|

||||

|

||||

Solid infill should have no gaps, pinholes, or separation from the perimeters.

|

||||

|

||||

Compared to with this feature disabled, where the internal solid infill and external-internal perimeters show signs of separation and under extrusion, when PA is tuned for optimal external perimeter performance as shown below.

|

||||

|

||||

|

||||

## How to calibrate the adaptive pressure advance model

|

||||

|

||||

### Defining the calibration sets

|

||||

|

||||

Firstly, it is important to understand your printer speed and acceleration limits in order to set meaningful boundaries for the calibrations:

|

||||

|

||||

1. **Upper acceleration range:** Do not attempt to calibrate adaptive PA for an acceleration that is larger than what the Klipper input shaper calibration tool recommends for your selected shaper. For example, if Klipper recommends an EI shaper with 4k maximum acceleration for your slowest axis (usually the Y axis), don’t calibrate adaptive PA beyond that value. This is because after 4k the input shaper smoothing is magnified and the perimeter separations that appear like PA issues are caused by the input shaper smoothing the shape of the corner. Basically, you’d be attempting to compensate for an input shaper artefact with PA.

|

||||

2. **Upper print speed range:** The Ellis PA pattern test has been proven to be the most efficient and effective test to run to calibrate adaptive PA. It is fast and allows for a reasonably accurate and easy-to-read PA value. However, the size of the line segments is quite small, which means that for the faster print speeds and slower accelerations, the toolhead will not be able to reach the full flow rate that we are calibrating against. It is therefore generally not recommended to attempt calibration with a print speed of higher than ~200-250mm/sec and accelerations slower than 1k in the PA pattern test. If your lowest acceleration is higher than 1k, then proportionally higher maximum print speeds can be used.

|

||||

|

||||

**Remember:** With the calibration process, we aim to create a PA – Flow Rate – Acceleration profile for the toolhead. As we cannot directly control flow rate, we use print speed as a proxy (higher speed -> higher flow).

|

||||

|

||||

With the above in mind, let’s create a worked example to identify the optimal number of PA tests to calibrate the adaptive PA model.

|

||||

|

||||

**The below starting points are recommended for the majority of Core XY printers:**

|

||||

|

||||

1. **Accelerations:** 1k, 2k, 4k

|

||||

2. **Print speeds:** 50mm/sec, 100mm/sec, 150mm/sec, 200mm/sec.

|

||||

|

||||

**That means we need to run 3x4 = 12 PA tests and identify the optimal PA for them.**

|

||||

|

||||

Finally, if the maximum acceleration given by input shaper is materially higher than 4k, run a set of tests with the higher accelerations. For example, if input shaper allows a 6k value, run PA tests as below:

|

||||

|

||||

1. **Accelerations:** 1k, 2k, 4k, 6k

|

||||

2. **Print speeds:** 50mm/sec, 100mm/sec, 150mm/sec, 200mm/sec.

|

||||

|

||||

Similarly, if the maximum value recommended is 12k, run PA tests as below:

|

||||

|

||||

1. **Accelerations:** 1k, 2k, 4k, 8k, 12k

|

||||

2. **Print speeds:** 50mm/sec, 100mm/sec, 150mm/sec, 200mm/sec.

|

||||

|

||||

So, at worst case you will need to run 5x4 = 20 PA tests if your printer acceleration is on the upper end! In essence, you want enough granularity of data points to create a meaningful model while also not overdoing it with the number of tests. So, doubling the speed and acceleration is a good compromise to arrive at the optimal number of tests.

|

||||

For this example, let’s assume that the baseline number of tests is adequate for your printer:

|

||||

|

||||

1. **Accelerations:** 1k, 2k, 4k

|

||||

2. **Print speeds:** 50mm/sec, 100mm/sec, 150mm/sec, 200mm/sec.

|

||||

|

||||

We, therefore, need to run 12 PA tests as below:

|

||||

|

||||

**Speed – Acceleration**

|

||||

|

||||

1. 50 – 1k

|

||||

2. 100 – 1k

|

||||

3. 150 – 1k

|

||||

4. 200 – 1k

|

||||

5. 50 – 2k

|

||||

6. 100 – 2k

|

||||

7. 150 – 2k

|

||||

8. 200 – 2k

|

||||

9. 50 – 4k

|

||||

10. 100 – 4k

|

||||

11. 150 – 4k

|

||||

12. 200 – 4k

|

||||

|

||||

### Identifying the flow rates from the print speed

|

||||

|

||||

#### OrcaSlicer 2.2.0 and later

|

||||

|

||||

Test parameters needed to build adaptive PA table are printed on the test sample:

|

||||

|

||||

<img width="452" alt="pa batch mode" src="https://github.com/user-attachments/assets/219c53b5-d53f-4360-963e-0985d9257bd7">

|

||||

|

||||

Test sample above was done with acceleration 12000 mm/s² and flow rate 27.13 mm³/s

|

||||

|

||||

#### OrcaSlicer 2.1.0 and older.

|

||||

|

||||

As mentioned earlier, **the print speed is used as a proxy to vary the extrusion flow rate**. Once your PA test is set up, change the gcode preview to “flow” and move the horizontal slider over one of the herringbone patterns and take note of the flow rate for different speeds.

|

||||

|

||||

|

||||

### Running the tests

|

||||

|

||||

#### General tips

|

||||

|

||||

It is recommended that the PA step is set to a small value, to allow you to make meaningful distinctions between the different tests – **therefore a PA step value of 0.001 is recommended. **

|

||||

|

||||

**Set the end PA to a value high enough to start showing perimeter separation for the lowest flow (print speed) and acceleration test.** For example, for a Voron 350 using Revo HF, the maximum value was set to 0.05 as that was sufficient to show perimeter separation even at the slowest flow rates and accelerations.

|

||||

|

||||

**If the test is too big to fit on the build plate, increase your starting PA value or the PA step value accordingly until the test can fit.** If the lowest value becomes too high and there is no ideal PA present in the test, focus on increasing the PA step value to reduce the number of herringbones printed (hence the size of the print).

|

||||

|

||||

<img width="402" alt="PA calibration parameters" src="https://github.com/user-attachments/assets/b411dc30-5556-4e7c-8c40-5279d3074eae">

|

||||

|

||||

#### OrcaSlicer 2.3.0 and newer

|

||||

|

||||

PA pattern calibration configuration window have been changed to simplify test setup. Now all is needed is to fill list of accelerations and speeds into relevant fields of the calibration window:

|

||||

|

||||

|

||||

|

||||

Test patterns generated for each acceleration-speed pair and all parameters are set accordingly. No additional actions needed from user side. Just slice and print all plates generated.

|

||||

|

||||

Refer to [Calibration Guide](./Calibration) for more details on batch mode calibration.

|

||||

|

||||

#### OrcaSlicer 2.2.0 and older

|

||||

|

||||

Setup your PA test as usual from the calibration menu in Orca slicer. Once setup, your PA test should look like the below:

|

||||

|

||||

<img width="437" alt="PA calibration test 1" src="https://github.com/user-attachments/assets/1e6159fe-c3c5-4480-95a1-4383f1fae422">

|

||||

|

||||

<img width="437" alt="Pa calibration test 2" src="https://github.com/user-attachments/assets/c360bb18-a97a-4f37-b5a3-bb0c67cac2b6">

|

||||

|

||||

Now input your identified print speeds and accelerations in the fields above and run the PA tests.

|

||||

|

||||

**IMPORTANT:** Make sure your acceleration values are all the same in all text boxes. Same for the print speed values and Jerk (XY) values. Make sure your Jerk value is set to the external perimeter jerk used in your print profiles.

|

||||

|

||||

#### Test results processing

|

||||

|

||||

Now run the tests and note the optimal PA value, the flow, and the acceleration. You should produce a table like this:

|

||||

|

||||

<img width="452" alt="calibration table" src="https://github.com/user-attachments/assets/9451e8e4-352f-4cfc-b835-dffa4420d580">

|

||||

|

||||

Concatenate the PA value, the flow value, and the acceleration value into the final comma-separated sets to create the values entered in the model as shown above.

|

||||

|

||||

**You’re now done! The PA profile is created and calibrated!**

|

||||

|

||||

Remember to paste the values in the adaptive pressure advance measurements text box as shown below, and save your filament profile.

|

||||

|

||||

<img width="452" alt="pa profile" src="https://github.com/user-attachments/assets/e6e61d1b-e422-4a6a-88ff-f55e10f79900">

|

||||

|

||||

### Tips

|

||||

|

||||

#### Model input:

|

||||

|

||||

The adaptive PA model built into the slicer is flexible enough to allow for as many or as few increments of flow and acceleration as you want. Ideally, you want at a minimum 3x data points for acceleration and flow in order to create a meaningful model.

|

||||

|

||||

However, if you don’t want to calibrate for flow, just run the acceleration tests and leave flow the same for each test (in which case you’ll input only 3 rows in the model text box). In this case, flow will be ignored when the model is used.

|

||||

|

||||

Similarly for acceleration – in the above example you’ll input only 4 rows in the model text box, in which case acceleration will be ignored when the model is used.

|

||||

|

||||

**However, make sure a triplet of values is always provided – PA value, Flow, Acceleration.**

|

||||

|

||||

#### Identifying the right PA:

|

||||

|

||||

Higher acceleration and higher flow rate PA tests are easier to identify the optimal PA as the range of “good” values is much narrower. It’s evident where the PA is too large, as gaps start to appear in the corner and where PA is too low, as the corner starts bulging.

|

||||

|

||||

However, the lower the flow rate and accelerations are, the range of good values is much wider. Having examined the PA tests even under a microscope, what is evident, is that if you can’t distinguish a value as being evidently better than another (i.e. sharper corner with no gaps) with the naked eye, then both values are correct. In which case, if you can’t find any meaningful difference, simply use the optimal values from the higher flow rates.

|

||||

|

||||

- **Too high PA**

|

||||

|

||||

|

||||

|

||||

- **Too low PA**

|

||||

|

||||

|

||||

|

||||

- **Optimal PA**

|

||||

|

||||

|

||||

60

doc/print_settings/calibration/cornering-calib.md

Normal file

60

doc/print_settings/calibration/cornering-calib.md

Normal file

|

|

@ -0,0 +1,60 @@

|

|||

# Cornering

|

||||

|

||||

Cornering is a critical aspect of 3D printing that affects the quality and accuracy of prints. It refers to how the printer handles changes in direction during movement, particularly at corners and curves. Proper cornering settings can help reduce artifacts like ringing, ghosting, and overshooting, leading to cleaner and more precise prints.

|

||||

|

||||

## Jerk

|

||||

|

||||

TODO: Jerk calibration not implemented yet.

|

||||

|

||||

## Junction Deviation

|

||||

|

||||

Junction Deviation is the default method for controlling cornering speed in MarlinFW (Marlin2) printers.

|

||||

Higher values result in more aggressive cornering speeds, while lower values produce smoother, more controlled cornering.

|

||||

The default value in Marlin is typically set to 0.08mm, which may be too high for some printers, potentially causing ringing. Consider lowering this value to reduce ringing, but avoid setting it too low, as this could lead to excessively slow cornering speeds.

|

||||

|

||||

1. Pre-requisites:

|

||||

1. Check if your printer has Junction Deviation enabled. You can do this by sending the command `M503` to your printer and looking for the line `Junction deviation: 0.25`.

|

||||

2. In OrcaSlicer, set:

|

||||

1. Acceleration high enough to trigger ringing (e.g., 2000 mm/s²).

|

||||

2. Speed high enough to trigger ringing (e.g., 100 mm/s).

|

||||

3. Use an opaque, high-gloss filament to make the ringing more visible.

|

||||

2. You need to print the Junction Deviation test.

|

||||

|

||||

|

||||

|

||||

1. Measure the X and Y heights and read the frequency set at that point in Orca Slicer.

|

||||

|

||||

|

||||

|

||||

|

||||

2. It’s very likely that you’ll need to set values lower than 0.08 mm, as shown in the previous example. To determine a more accurate maximum JD value, you can print a new calibration tower with a maximum value set at the point where the corners start losing sharpness.

|

||||

3. Print the second Junction Deviation test with the new maximum value.

|

||||

|

||||

|

||||

|

||||

4. Measure the X and Y heights and read the frequency set at that point in Orca Slicer.

|

||||

|

||||

|

||||

|

||||

|

||||

3. Save the settings

|

||||

1. Set your Maximun Junction Deviation value in [Printer settings/Motion ability/Jerk limitation].

|

||||

2. Use the following G-code to set the mm:

|

||||

```gcode

|

||||

M205 J#JunctionDeviationValue

|

||||

M500

|

||||

```

|

||||

Example

|

||||

```gcode

|

||||

M205 J0.012

|

||||

M500

|

||||

```

|

||||

3. Recompile your MarlinFW

|

||||

1. In Configuration.h uncomment and set:

|

||||

```cpp

|

||||

#define JUNCTION_DEVIATION_MM 0.012 // (mm) Distance from real junction edge

|

||||

```

|

||||

2. Check Classic Jerk is disabled (commented).

|

||||

```cpp

|

||||

//#define CLASSIC_JERK

|

||||

```

|

||||

33

doc/print_settings/calibration/flow-rate-calib.md

Normal file

33

doc/print_settings/calibration/flow-rate-calib.md

Normal file

|

|

@ -0,0 +1,33 @@

|

|||

# Flow rate

|

||||

|

||||

The Flow Ratio determines how much filament is extruded and plays a key role in achieving high-quality prints. A properly calibrated flow ratio ensures consistent layer adhesion and accurate dimensions. If the flow ratio is too low, under-extrusion may occur, leading to gaps, weak layers, and poor structural integrity. On the other hand, a flow ratio that is too high can cause over-extrusion, resulting in excess material, rough surfaces, and dimensional inaccuracies.

|

||||

|

||||

> [!WARNING]

|

||||

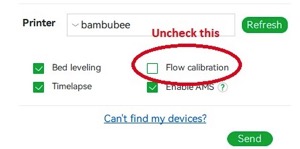

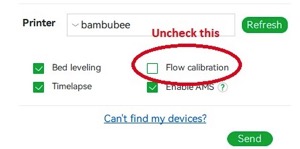

> For Bambulab X1/X1C users, make sure you do not select the 'Flow calibration' option.

|

||||

|

||||

>

|

||||

|

||||

> [!IMPORTANT]

|

||||

> PASS 1 and PASS 2 follow the older flow ratio formula `FlowRatio_old*(100 + modifier)/100`. YOLO (Recommended) and YOLO (perfectist version) use a new system that is very simple `FlowRatio_old±modifier`.

|

||||

|

||||

|

||||

|

||||

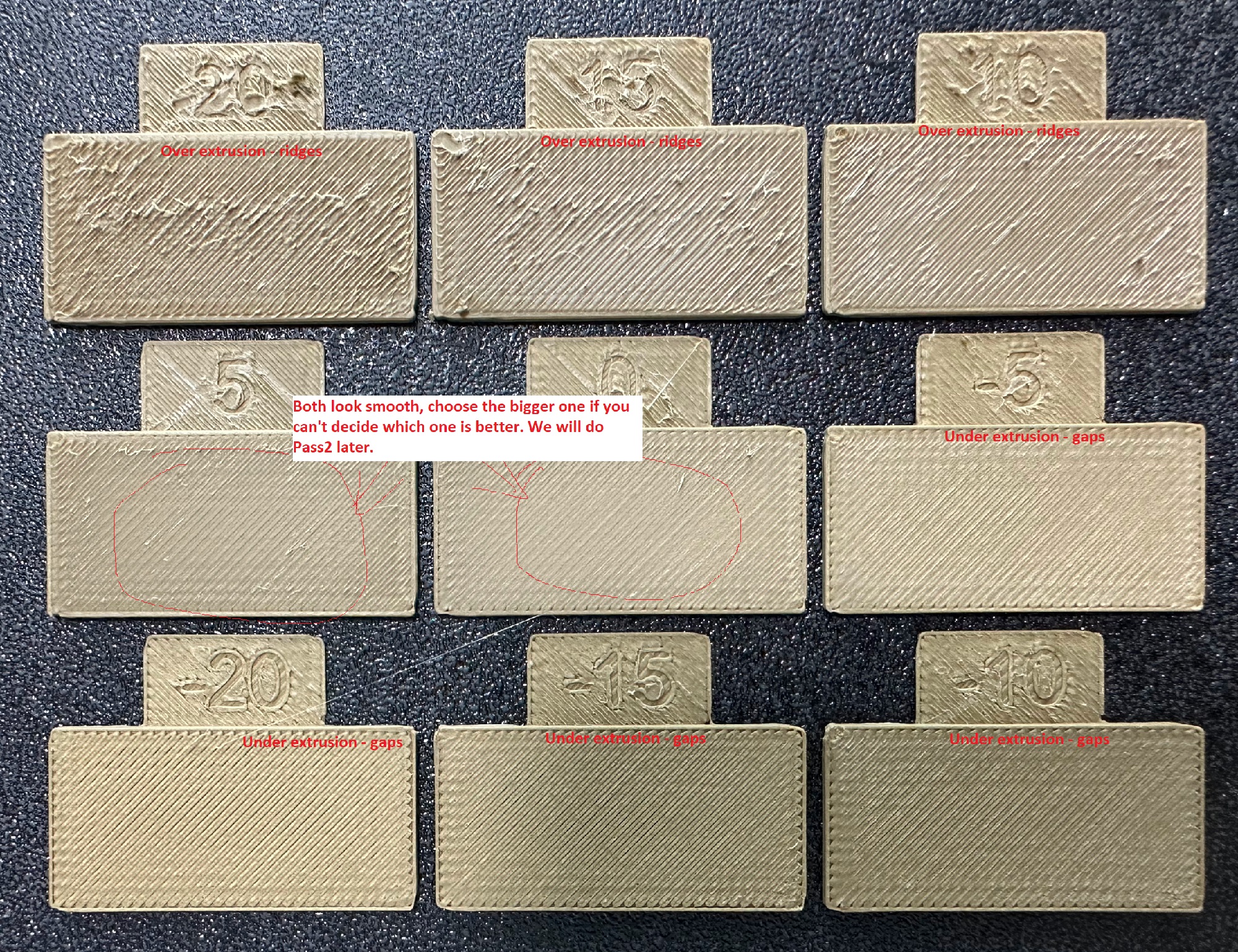

Calibrating the flow rate involves a two-step process.

|

||||

|

||||

1. Select the printer, filament, and process you would like to use for the test.

|

||||

2. Select `Pass 1` in the `Calibration` menu

|

||||

3. A new project consisting of nine blocks will be created, each with a different flow rate modifier. Slice and print the project.

|

||||

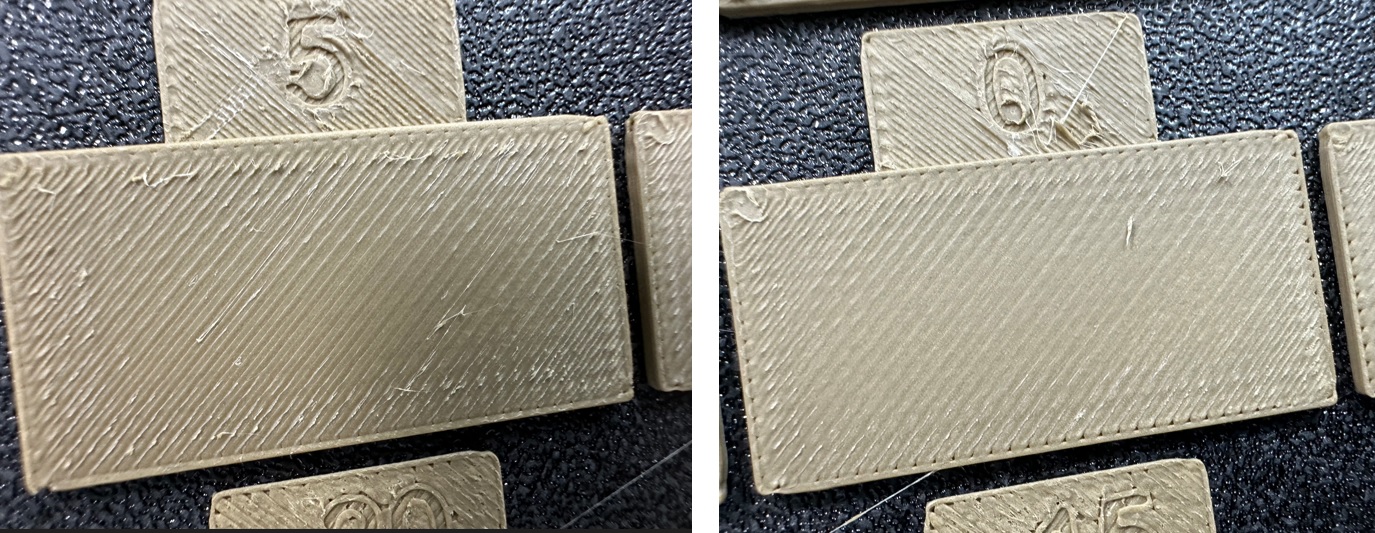

4. Examine the blocks and determine which one has the smoothest top surface.

|

||||

|

||||

|

||||

|

||||

5. Update the flow ratio in the filament settings using the following equation: `FlowRatio_old*(100 + modifier)/100`. If your previous flow ratio was `0.98` and you selected the block with a flow rate modifier of `+5`, the new value should be calculated as follows: `0.98x(100+5)/100 = 1.029`.** Remember** to save the filament profile.

|

||||

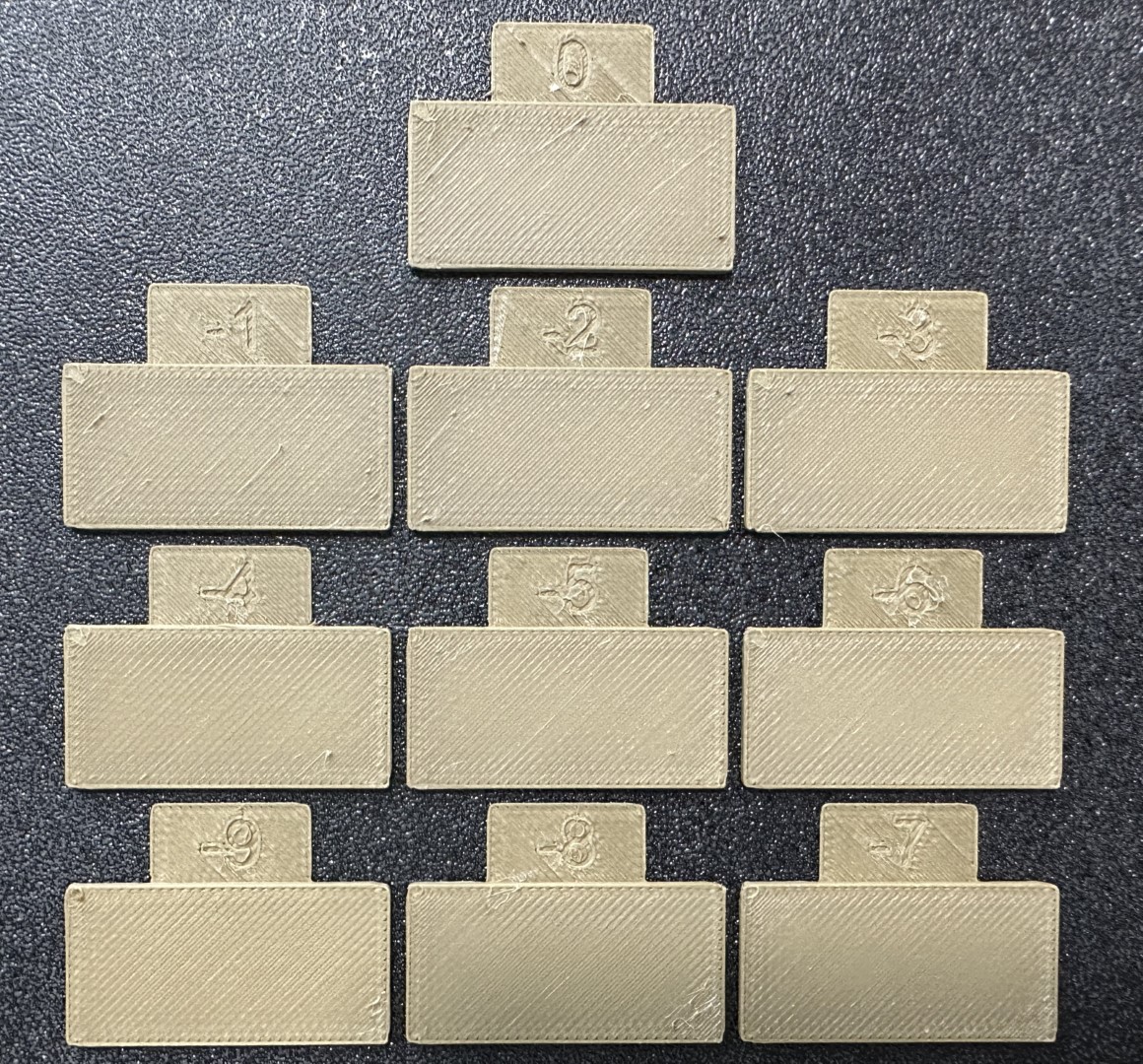

6. Perform the `Pass 2` calibration. This process is similar to `Pass 1`, but a new project with ten blocks will be generated. The flow rate modifiers for this project will range from `-9 to 0`.

|

||||

7. Repeat steps 4. and 5. In this case, if your previous flow ratio was 1.029 and you selected the block with a flow rate modifier of -6, the new value should be calculated as follows: `1.029x(100-6)/100 = 0.96726`. **Remember** to save the filament profile.

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

> [!TIP]

|

||||

> @ItsDeidara has made a html to help with the calculation. Check it out if those equations give you a headache [here](https://github.com/ItsDeidara/Orca-Slicer-Assistant).

|

||||

125

doc/print_settings/calibration/input-shaping-calib.md

Normal file

125

doc/print_settings/calibration/input-shaping-calib.md

Normal file

|

|

@ -0,0 +1,125 @@

|

|||

# Input Shaping

|

||||

|

||||

During high-speed movements, vibrations can cause a phenomenon called "ringing," where periodic ripples appear on the print surface. Input Shaping provides an effective solution by counteracting these vibrations, improving print quality and reducing wear on components without needing to significantly lower print speeds.

|

||||

|

||||

- [Klipper](#klipper)

|

||||

- [Marlin](#marlin)

|

||||

|

||||

## Klipper

|

||||

|

||||

### Resonance Compensation

|

||||

|

||||

The Klipper Resonance Compensation is a set of Input Shaping modes that can be used to reduce ringing and improve print quality.

|

||||

Ussualy the recommended values modes are `MZV` or `EI` for Delta printers.

|

||||

|

||||

1. Pre-requisites:

|

||||

1. In OrcaSlicer, set:

|

||||

1. Acceleration high enough to trigger ringing (e.g., 2000 mm/s²).

|

||||

2. Speed high enough to trigger ringing (e.g., 100 mm/s).

|

||||

|

||||

> [!NOTE]

|

||||

> These settings depend on your printer's motion ability and the filament's max volumetric speed. If you can't reach speeds that cause ringing, try increasing the filament's max volumetric speed (avoid materials below 10 mm³/s).

|

||||

3. Jerk [Klipper Square Corner Velocity](https://www.klipper3d.org/Kinematics.html?h=square+corner+velocity#look-ahead) to 5 or a high value (e.g., 20).

|

||||

2. In printer settigs:

|

||||

1. Set the Shaper Type to `MZV` or `EI`.

|

||||

```gcode

|

||||

SET_INPUT_SHAPER SHAPER_TYPE=MZV

|

||||

```

|

||||

2. Disable [Minimun Cruise Ratio](https://www.klipper3d.org/Kinematics.html#minimum-cruise-ratio) with:

|

||||

```gcode

|

||||

SET_VELOCITY_LIMIT MINIMUM_CRUISE_RATIO=0

|

||||

```

|

||||

3. Use an opaque, high-gloss filament to make the ringing more visible.

|

||||

2. Print the Input Shaping Frequency test with a range of frequencies.

|

||||

|

||||

|

||||

|

||||

1. Measure the X and Y heights and read the frequency set at that point in Orca Slicer.

|

||||

|

||||

|

||||

|

||||

|

||||

2. If not a clear result, you can measure a X and Y min and max acceptable heights and repeat the test with that min and max value.

|

||||

|

||||

> [!Warning]

|

||||

> There is a chance you will need to set higher than 60Hz frequencies. Some printers with very rigid frames and excellent mechanics may exhibit frequencies exceeding 100Hz.

|

||||

|

||||

3. Print the Damping test setting your X and Y frequency to the value you found in the previous step.

|

||||

|

||||

|

||||

|

||||

1. Measure the X and Y heights and read the damping set at that point in Orca Slicer.

|

||||

|

||||

|

||||

|

||||

|

||||

> [!Important]

|

||||

> Not all Resonance Compensation modes support damping.

|

||||

|

||||

4. Restore your 3D Printer settings to avoid keep using high acceleration and jerk values.

|

||||

5. Save the settings

|

||||

1. You need to go to the printer settings and set the X and Y frequency and damp to the value you found in the previous step.

|

||||

|

||||

## Marlin

|

||||

|

||||

### ZV Input Shaping

|

||||

|

||||

ZV Input Shaping introduces an anti-vibration signal into the stepper motion for the X and Y axes. It works by splitting the step count into two halves: the first at half the frequency and the second as an "echo," delayed by half the ringing interval. This simple approach effectively reduces vibrations, improving print quality and allowing for higher speeds.

|

||||

|

||||

1. Pre-requisites:

|

||||

1. In OrcaSlicer, set:

|

||||

1. Acceleration high enough to trigger ringing (e.g., 2000 mm/s²).

|

||||

2. Speed high enough to trigger ringing (e.g., 100 mm/s).

|

||||

> [!NOTE]

|

||||

> These settings depend on your printer's motion ability and the filament's max volumetric speed. If you can't reach speeds that cause ringing, try increasing the filament's max volumetric speed (avoid materials below 10 mm³/s).

|

||||

3. Jerk

|

||||

1. If using [Classic Jerk](https://marlinfw.org/docs/configuration/configuration.html#jerk-) use a high value (e.g., 20).

|

||||

2. If using [Junction Deviation](https://marlinfw.org/docs/features/junction_deviation.html) (new Marlin default mode) this test will use 0.25 (high enough to most printers).

|

||||

2. Use an opaque, high-gloss filament to make the ringing more visible.

|

||||

2. Print the Input Shaping Frequency test with a range of frequencies.

|

||||

|

||||

|

||||

|

||||

1. Measure the X and Y heights and read the frequency set at that point in Orca Slicer.

|

||||

|

||||

|

||||

|

||||

|

||||

2. If not a clear result, you can measure a X and Y min and max acceptable heights and repeat the test with that min and max value.

|

||||

|

||||

> [!Warning]

|

||||

> There is a chance you will need to set higher than 60Hz frequencies. Some printers with very rigid frames and excellent mechanics may exhibit frequencies exceeding 100Hz.

|

||||

|

||||

3. Print the Damping test setting your X and Y frequency to the value you found in the previous step.

|

||||

|

||||

|

||||

|

||||

1. Measure the X and Y heights and read the damping set at that point in Orca Slicer.

|

||||

|

||||

|

||||

|

||||

|

||||

4. Restore your 3D Printer settings to avoid keep using high acceleration and jerk values.

|

||||

1. Reboot your printer.

|

||||

2. Use the following G-code to restore your printer settings:

|

||||

```gcode

|

||||

M501

|

||||

```

|

||||

5. Save the settings

|

||||

1. You need to go to the printer settings and set the X and Y frequency and damp to the value you found in the previous step.

|

||||

2. Use the following G-code to set the frequency:

|

||||

```gcode

|

||||

M593 X F#Xfrequency D#XDamping

|

||||

M593 Y F#Yfrequency D#YDamping

|

||||

M500

|

||||

```

|

||||

Example

|

||||

```gcode

|

||||

M593 X F37.25 D0.16

|

||||

M593 Y F37.5 D0.06

|

||||

M500

|

||||

```

|

||||

|

||||

### Fixed-Time Motion

|

||||

|

||||

TODO This calibration test is currently under development. See the [Marlin documentation](https://marlinfw.org/docs/gcode/M493.html) for more information.

|

||||

77

doc/print_settings/calibration/pressure-advance-calib.md

Normal file

77

doc/print_settings/calibration/pressure-advance-calib.md

Normal file

|

|

@ -0,0 +1,77 @@

|

|||

# Pressure Advance

|

||||

|

||||

Pressure Advance is a feature that compensates for the lag in filament pressure within the nozzle during acceleration and deceleration. It helps improve print quality by reducing issues like blobs, oozing, and inconsistent extrusion, especially at corners or during fast movements.

|

||||

|

||||

Orca Slicer includes three approaches for calibrating the pressure advance value. Each method has its own advantages and disadvantages. It is important to note that each method has two versions: one for a direct drive extruder and one for a Bowden extruder. Make sure to select the appropriate version for your test.

|

||||

|

||||

> [!NOTE]

|

||||

> [Adaptive Pressure Advance Guide](print_settings/calibration/adaptive-pressure-advance-calib.md)

|

||||

|

||||

> [!WARNING]

|

||||

> For Marlin: Linear advance must be enabled in firmware (M900). **Not all printers have it enabled by default.**

|

||||

|

||||

> [!WARNING]

|

||||

> For Bambulab X1/X1C users, make sure you do not select the 'Flow calibration' option when printings.

|

||||

>

|

||||

>

|

||||

|

||||

## Line method

|

||||

|

||||

The line method is quick and straightforward to test. However, its accuracy highly depends on your first layer quality. It is suggested to turn on the bed mesh leveling for this test.

|

||||

Steps:

|

||||

|

||||

1. Select the printer, filament, and process you would like to use for the test.

|

||||

2. Print the project and check the result. You can select the value of the most even line and update your PA value in the filament settings.

|

||||

3. In this test, a PA value of `0.016` appears to be optimal.

|

||||

|

||||

|

||||

<img width="1003" alt="Screenshot 2022-12-31 at 12 11 10 PM" src="https://user-images.githubusercontent.com/103989404/210124449-dd828da8-a7e4-46b8-9fa2-8bed5605d9f6.png">

|

||||

|

||||

|

||||

|

||||

|

||||

## Pattern method

|

||||

|

||||

The pattern method is adapted from [Andrew Ellis' pattern method generator](https://ellis3dp.com/Pressure_Linear_Advance_Tool/), which was itself derived from the [Marlin pattern method](https://marlinfw.org/tools/lin_advance/k-factor.html) developed by [Sineos](https://github.com/Sineos/k-factorjs).

|

||||

|

||||

[Instructions for using and reading the pattern method](https://ellis3dp.com/Print-Tuning-Guide/articles/pressure_linear_advance/pattern_method.html) are provided in [Ellis' Print Tuning Guide](https://ellis3dp.com/Print-Tuning-Guide/), with only a few Orca Slicer differences to note.

|

||||

|

||||

Test configuration window allow user to generate one or more tests in a single projects. Multiple tests will be placed on each plate with extra plates added if needed.

|

||||

|

||||

1. Single test \

|

||||

|

||||

2. Batch mode testing (multiple tests on a sinle plate) \

|

||||

|

||||

|

||||

Once test generated, one or more small rectangular prisms could be found on the plate, one for each test case. This object serves a few purposes:

|

||||

|

||||

1. The test pattern itself is added in as custom G-Code at each layer, same as you could do by hand actually. The rectangular prism gives us the layers in which to insert that G-Code. This also means that **you'll see the full test pattern when you move to the Preview pane**:

|

||||

|

||||

|

||||

|

||||

1. The prism acts as a handle, enabling you to move the test pattern wherever you'd like on the plate by moving the prism

|

||||

2. Each test object is pre-configured with target parameters which are reflected in the objects name. However, test parameters may be adjusted for each prism individually by referring to the object list pane:

|

||||

|

||||

|

||||

|

||||

Next, Ellis' generator provided the ability to adjust specific printer, filament, and print profile settings. You can make these same changes in Orca Slicer by adjusting the settings in the Prepare pane as you would with any other print. When you initiate the calibration test, Ellis' default settings are applied. A few things to note about these settings:

|

||||

|

||||

1. Ellis specified line widths as a percent of filament diameter. The Orca pattern method does the same to provide its suggested defaults, making use of Ellis' percentages in combination with your specified nozzle diameter

|

||||

2. In terms of line width, the pattern only makes use of the `Default` and `First layer` widths

|

||||

3. In terms of speed, the pattern only uses the `First layer speed -> First layer` and `Other layers speed -> Outer wall` speeds

|

||||

4. The infill pattern beneath the numbers cannot be changed becuase it's not actually an infill pattern pulled from the settings. All of the pattern G-Code is custom written, so that "infill" is, effectively, hand-drawn and so not processed through the usual channels that would enable Orca to recognize it as infill

|

||||

|

||||

## Tower method

|

||||

|

||||

The tower method may take a bit more time to complete, but it does not rely on the quality of the first layer.

|

||||

The PA value for this test will be increased by 0.002 for every 1 mm increase in height. (**NOTE** 0.02 for Bowden)

|

||||

|

||||

1. Select the printer, filament, and process you would like to use for the test.

|

||||

2. Examine each corner of the print and mark the height that yields the best overall result.

|

||||

3. I selected a height of 8 mm for this case, so the pressure advance value should be calculated as `PressureAdvanceStart+(PressureAdvanceStep x measured)` example: `0+(0.002 x 8) = 0.016`.

|

||||

|

||||

|

||||

|

||||

|

||||

> [!TIP]

|

||||

> @ItsDeidara has made a html to help with the calculation. Check it out if those equations give you a headache [here](https://github.com/ItsDeidara/Orca-Slicer-Assistant).

|

||||

20

doc/print_settings/calibration/retraction-calib.md

Normal file

20

doc/print_settings/calibration/retraction-calib.md

Normal file

|

|

@ -0,0 +1,20 @@

|

|||

# Retraction test

|

||||

|

||||

Retraction is the process of pulling the filament back into the nozzle to prevent oozing and stringing during non-print moves. If the retraction length is too short, it may not effectively prevent oozing, while if it's too long, it can lead to clogs or under-extrusion. Filaments like PETG and TPU are more prone to stringing, so they may require longer retraction lengths compared to PLA or ABS.

|

||||

|

||||

This test generates a retraction tower automatically. The retraction tower is a vertical structure with multiple notches, each printed at a different retraction length. After the print is complete, we can examine each section of the tower to determine the optimal retraction length for the filament. The optimal retraction length is the shortest one that produces the cleanest tower.

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

In the dialog, you can select the start and end retraction length, as well as the retraction length increment step. The default values are 0mm for the start retraction length, 2mm for the end retraction length, and 0.1mm for the step. These values are suitable for most direct drive extruders. However, for Bowden extruders, you may want to increase the start and end retraction lengths to 1mm and 6mm, respectively, and set the step to 0.2mm.

|

||||

|

||||

|

||||

|

||||

> [!NOTE]

|

||||

> When testing filaments such as PLA or ABS that have minimal oozing, the retraction settings can be highly effective. You may find that the retraction tower appears clean right from the start. In such situations, setting the retraction length to 0.2mm - 0.4mm using Orca Slicer should suffice.

|

||||

> On the other hand, if there is still a lot of stringing at the top of the tower, it is recommended to dry your filament and ensure that your nozzle is properly installed without any leaks.

|

||||

|

||||

> [!TIP]

|

||||

> @ItsDeidara has made a html to help with the calculation. Check it out if those equations give you a headache [here](https://github.com/ItsDeidara/Orca-Slicer-Assistant).

|

||||

29

doc/print_settings/calibration/temp-calib.md

Normal file

29

doc/print_settings/calibration/temp-calib.md

Normal file

|

|

@ -0,0 +1,29 @@

|

|||

# Temp Calibration

|

||||

|

||||

In FDM 3D printing, the temperature is a critical factor that affects the quality of the print.

|

||||

There is no other calibration that can have such a big impact on the print quality as temperature calibration.

|

||||

|

||||

## Nozzle Temp tower

|

||||

|

||||

Nozzle temperature is one of the most important settings to calibrate for a successful print. The temperature of the nozzle affects the viscosity of the filament, which in turn affects how well it flows through the nozzle and adheres to the print bed. If the temperature is too low, the filament may not flow properly, leading to under-extrusion, poor layer adhesion and stringing. If the temperature is too high, the filament may degrade, over-extrude and produce stringing.

|

||||

|

||||

|

||||

|

||||

Temp tower is a straightforward test. The temp tower is a vertical tower with multiple blocks, each printed at a different temperature. Once the print is complete, we can examine each block of the tower and determine the optimal temperature for the filament. The optimal temperature is the one that produces the highest quality print with the least amount of issues, such as stringing, layer adhesion, warping (overhang), and bridging.

|

||||

|

||||

|

||||

|

||||

## Bed temperature

|

||||

|

||||

Bed temperature is another important setting to calibrate for a successful print. The bed temperature affects the adhesion of the filament to the print bed, which in turn affects the overall quality of the print. If the bed temperature is too low, the filament may not adhere properly to the print bed, leading to warping and poor layer adhesion. If the bed temperature is too high, the filament may become too soft and lose its shape, leading to over-extrusion and poor layer adhesion.

|

||||

|

||||

This setting doesn't have a specific test, but it is recommended to start with the recommended bed temperature for the filament and adjust it based on the filament manufacturer's recommendations.

|

||||

|

||||

## Chamber temperature

|

||||

|

||||

Chamber temperature can affect the print quality, especially for high-temperature filaments. A heated chamber can help to maintain a consistent temperature throughout the print, reducing the risk of warping and improving layer adhesion. However, it is important to monitor the chamber temperature to ensure that it does not exceed the recommended temperature for the filament being used.

|

||||

|

||||

See: [Chamber temperature printer settings](../../Chamber-temperature.md)

|

||||

|

||||

> [!NOTE]

|

||||

> Low temperature Filaments like PLA can clog the nozzle if the chamber temperature is too high.

|

||||

31

doc/print_settings/calibration/tolerance-calib.md

Normal file

31

doc/print_settings/calibration/tolerance-calib.md

Normal file

|

|

@ -0,0 +1,31 @@

|

|||

# Filament Tolerance Calibration

|

||||

|

||||

Each filament and printer combination can result in different tolerances. This means that even using the same filament and print profile, tolerances may vary from one printer to another.

|

||||

To correct for these variations, Orca Slicer provides:

|

||||

|

||||

- Filament Compensation:

|

||||

|

||||

- Shrinkage (XY)

|

||||

|

||||

|

||||

|

||||

- Process Compensation:

|

||||

|

||||

- X-Y hole compensation

|

||||

- X-Y contour compensation

|

||||

- Precise wall

|

||||

- Precise Z height

|

||||

|

||||

|

||||

|

||||

## Orca Tolerance Test

|

||||

|

||||

This calibration test is designed to evaluate the dimensional accuracy of your printer and filament. The model consists of a base with six hexagonal holes, each with a different tolerance: 0.0 mm, 0.05 mm, 0.1 mm, 0.2 mm, 0.3 mm, and 0.4 mm, as well as a hexagon-shaped tester.

|

||||

|

||||

|

||||

|

||||

You can check the tolerance using either an M6 Allen key or the included printed hexagon tester.

|

||||

Use calipers to measure both the holes and the inner tester. Based on your results, you can fine-tune the X-Y hole compensation and X-Y contour compensation settings. Repeat the process until you achieve the desired precision.

|

||||

|

||||

|

||||

|

||||

23

doc/print_settings/calibration/volumetric-speed-calib.md

Normal file

23

doc/print_settings/calibration/volumetric-speed-calib.md

Normal file

|

|

@ -0,0 +1,23 @@

|

|||

# Max Volumetric speed

|

||||

|

||||

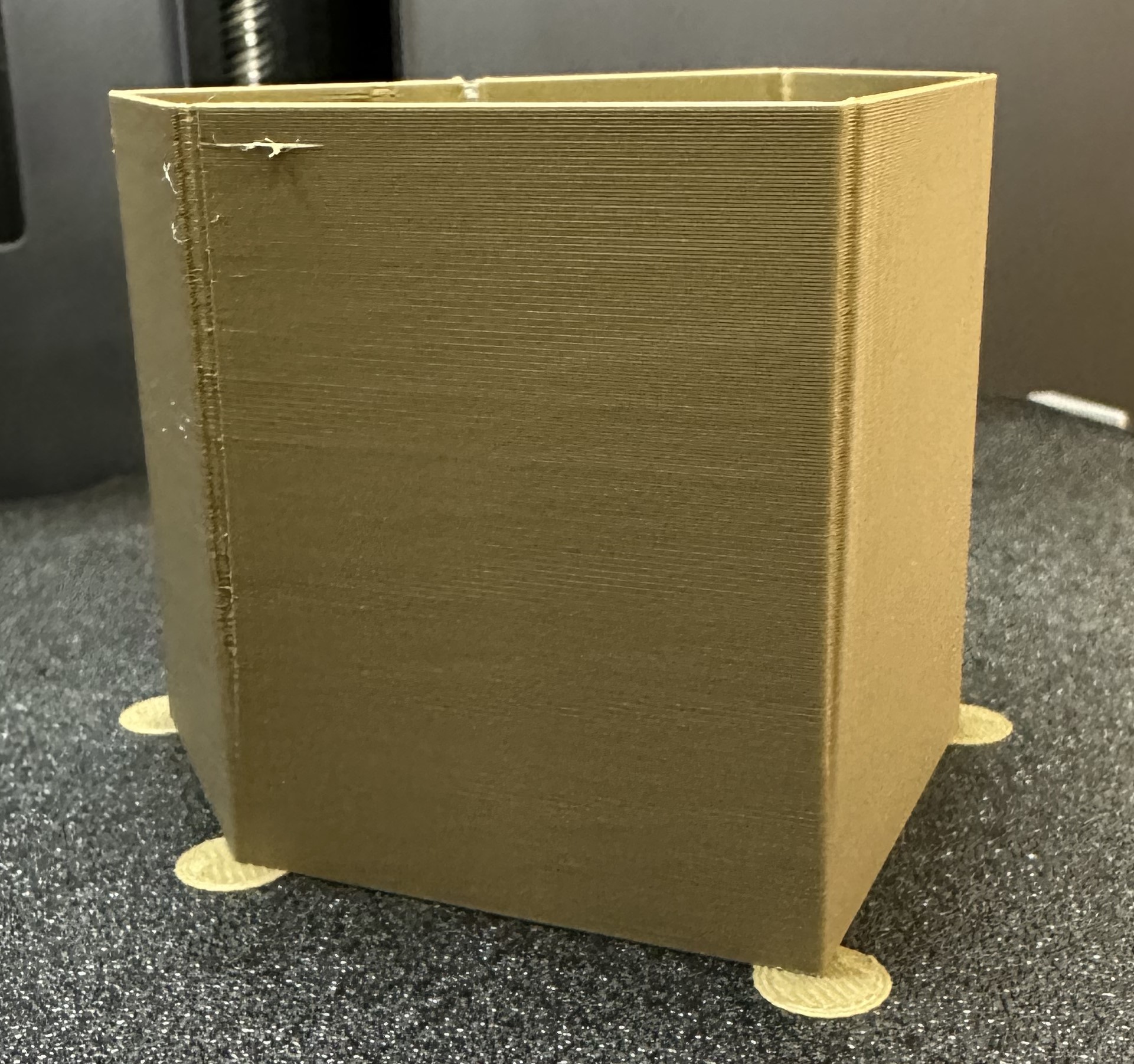

This is a test designed to calibrate the maximum volumetric speed of the specific filament. The generic or 3rd party filament types may not have the correct volumetric flow rate set in the filament. This test will help you to find the maximum volumetric speed of the filament.

|

||||

|

||||

You will be promted to enter the settings for the test: start volumetric speed, end volumentric speed, and step. It is recommended to use the default values (5mm³/s start, 20mm³/s end, with a step of 0.5), unless you already have an idea of the lower or upper limit for your filament. Select "OK", slice the plate, and send it to the printer.

|

||||

|

||||

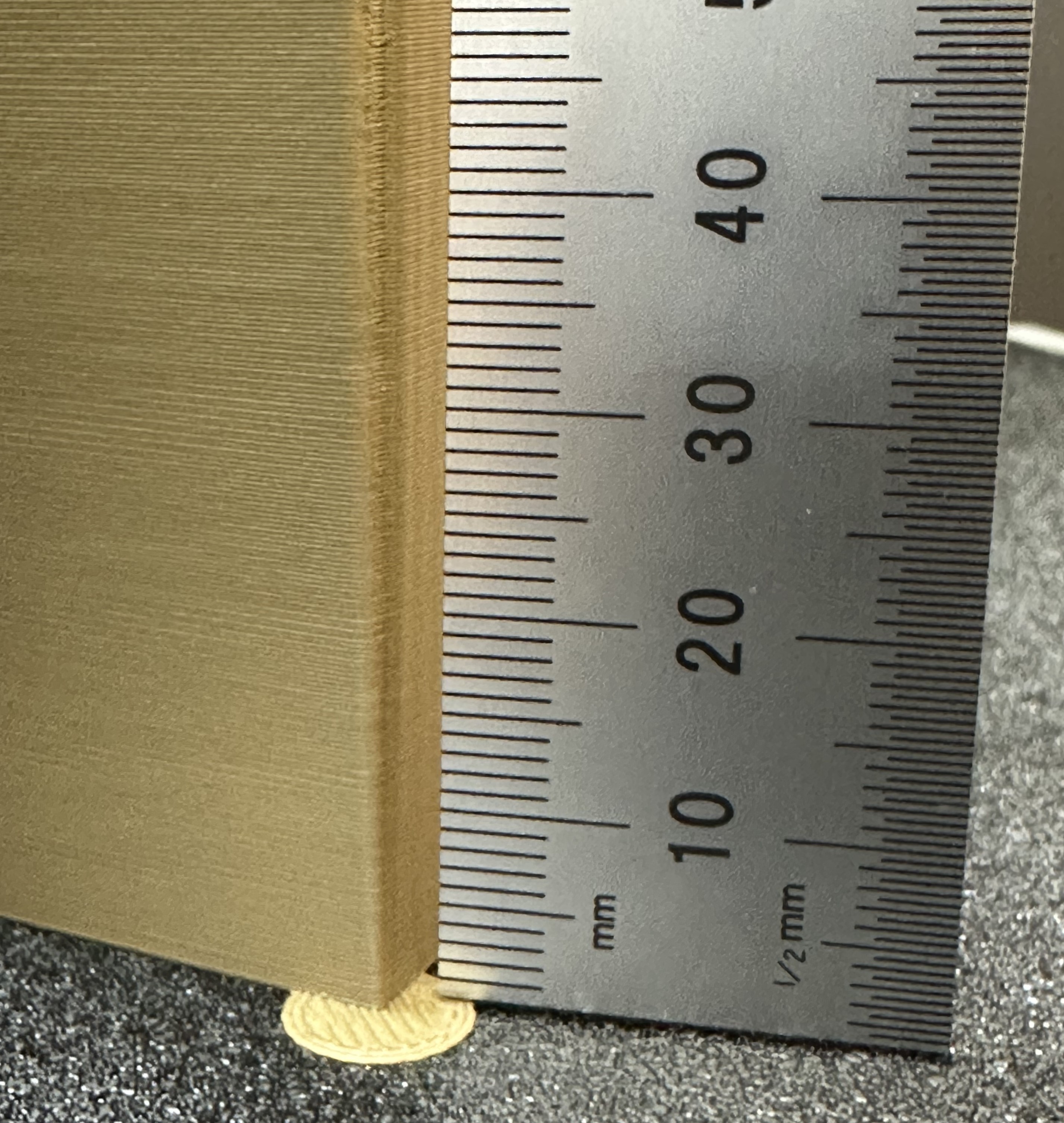

Once printed, take note of where the layers begin to fail and where the quality begins to suffer. Pay attention to changes from matte to shiny as well.

|

||||

|

||||

|

||||

|

||||

Using calipers or a ruler, measure the height of the print at that point. Use the following calculation to determine the correct max flow value: `start + (height-measured * step)` . For example in the photo below, and using the default setting values, the print quality began to suffer at 19mm measured, so the calculation would be: `5 + (19 * 0.5)` , or `13mm³/s` using the default values. Enter your number into the "Max volumetric speed" value in the filament settings.

|

||||

|

||||

|

||||

|

||||

You can also return to OrcaSlicer in the "Preview" tab, make sure the color scheme "flow" is selected. Scroll down to the layer height that you measured, and click on the toolhead slider. This will indicate the max flow level for your filmanet.

|

||||

|

||||

|

||||

|

||||

> [!NOTE]

|

||||

> You may also choose to conservatively reduce the flow by 5-10% to ensure print quality.

|

||||

|

||||

> [!TIP]

|

||||

> @ItsDeidara has made a html to help with the calculation. Check it out if those equations give you a headache [here](https://github.com/ItsDeidara/Orca-Slicer-Assistant).

|

||||

Loading…

Add table

Add a link

Reference in a new issue