mirror of

https://github.com/SoftFever/OrcaSlicer.git

synced 2026-02-24 05:15:03 -07:00

Merge branch 'main' into dev/bbl-network-upd

This commit is contained in:

commit

3d64af917a

26 changed files with 164 additions and 155 deletions

|

|

@ -130,7 +130,7 @@ fi

|

|||

if [[ -n "${BUILD_DEPS}" ]]

|

||||

then

|

||||

echo "Configuring dependencies..."

|

||||

BUILD_ARGS="-DDEP_WX_GTK3=ON"

|

||||

BUILD_ARGS="${DEPS_EXTRA_BUILD_ARGS} -DDEP_WX_GTK3=ON"

|

||||

if [[ -n "${CLEAN_BUILD}" ]]

|

||||

then

|

||||

rm -fr deps/build

|

||||

|

|

@ -164,10 +164,10 @@ then

|

|||

then

|

||||

rm -fr build

|

||||

fi

|

||||

BUILD_ARGS=""

|

||||

BUILD_ARGS="${ORCA_EXTRA_BUILD_ARGS}"

|

||||

if [[ -n "${FOUND_GTK3_DEV}" ]]

|

||||

then

|

||||

BUILD_ARGS="-DSLIC3R_GTK=3"

|

||||

BUILD_ARGS="${BUILD_ARGS} -DSLIC3R_GTK=3"

|

||||

fi

|

||||

if [[ -n "${BUILD_DEBUG}" ]]

|

||||

then

|

||||

|

|

|

|||

|

|

@ -26,7 +26,7 @@

|

|||

# Flow rate

|

||||

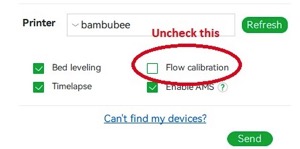

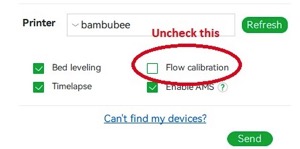

> [!WARNING]

|

||||

> For Bambulab X1/X1C users, make sure you do not select the 'Flow calibration' option.

|

||||

>

|

||||

>

|

||||

>

|

||||

|

||||

> [!IMPORTANT]

|

||||

|

|

@ -34,7 +34,7 @@

|

|||

|

||||

|

||||

|

||||

Calibrating the flow rate involves a two-step process.

|

||||

Calibrating the flow rate involves a two-step process.

|

||||

Steps

|

||||

1. Select the printer, filament, and process you would like to use for the test.

|

||||

2. Select `Pass 1` in the `Calibration` menu

|

||||

|

|

@ -45,11 +45,11 @@ Steps

|

|||

|

||||

5. Update the flow ratio in the filament settings using the following equation: `FlowRatio_old*(100 + modifier)/100`. If your previous flow ratio was `0.98` and you selected the block with a flow rate modifier of `+5`, the new value should be calculated as follows: `0.98x(100+5)/100 = 1.029`.** Remember** to save the filament profile.

|

||||

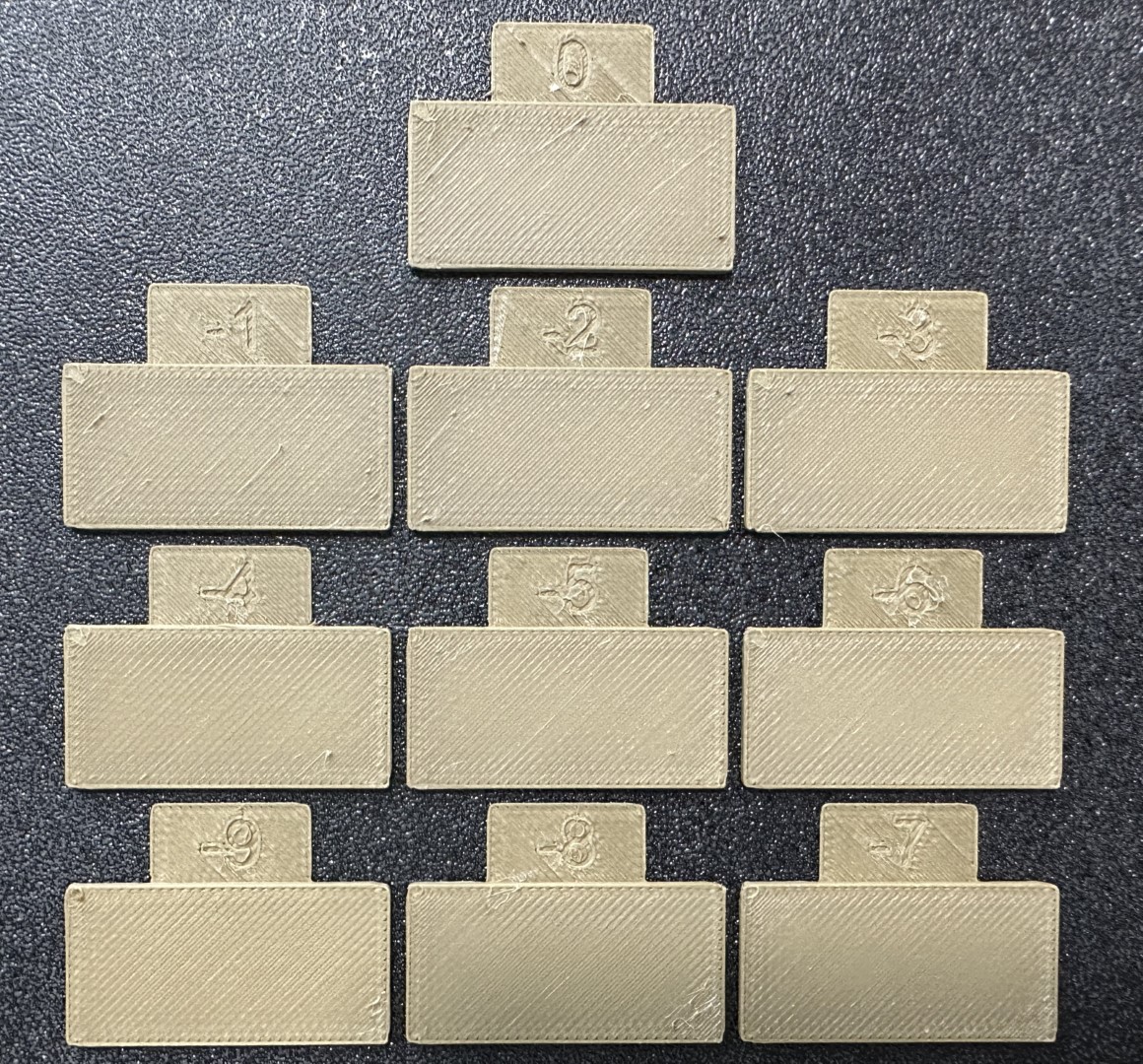

6. Perform the `Pass 2` calibration. This process is similar to `Pass 1`, but a new project with ten blocks will be generated. The flow rate modifiers for this project will range from `-9 to 0`.

|

||||

7. Repeat steps 4. and 5. In this case, if your previous flow ratio was 1.029 and you selected the block with a flow rate modifier of -6, the new value should be calculated as follows: `1.029x(100-6)/100 = 0.96726`. **Remember** to save the filament profile.

|

||||

7. Repeat steps 4. and 5. In this case, if your previous flow ratio was 1.029 and you selected the block with a flow rate modifier of -6, the new value should be calculated as follows: `1.029x(100-6)/100 = 0.96726`. **Remember** to save the filament profile.

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

# Pressure Advance

|

||||

|

||||

|

|

@ -60,7 +60,7 @@ Orca Slicer includes three approaches for calibrating the pressure advance value

|

|||

|

||||

> [!WARNING]

|

||||

> For Bambulab X1/X1C users, make sure you do not select the 'Flow calibration' option when printings.

|

||||

>

|

||||

>

|

||||

>

|

||||

|

||||

### Line method

|

||||

|

|

@ -107,8 +107,8 @@ Next, Ellis' generator provided the ability to adjust specific printer, filament

|

|||

|

||||

### Tower method

|

||||

|

||||

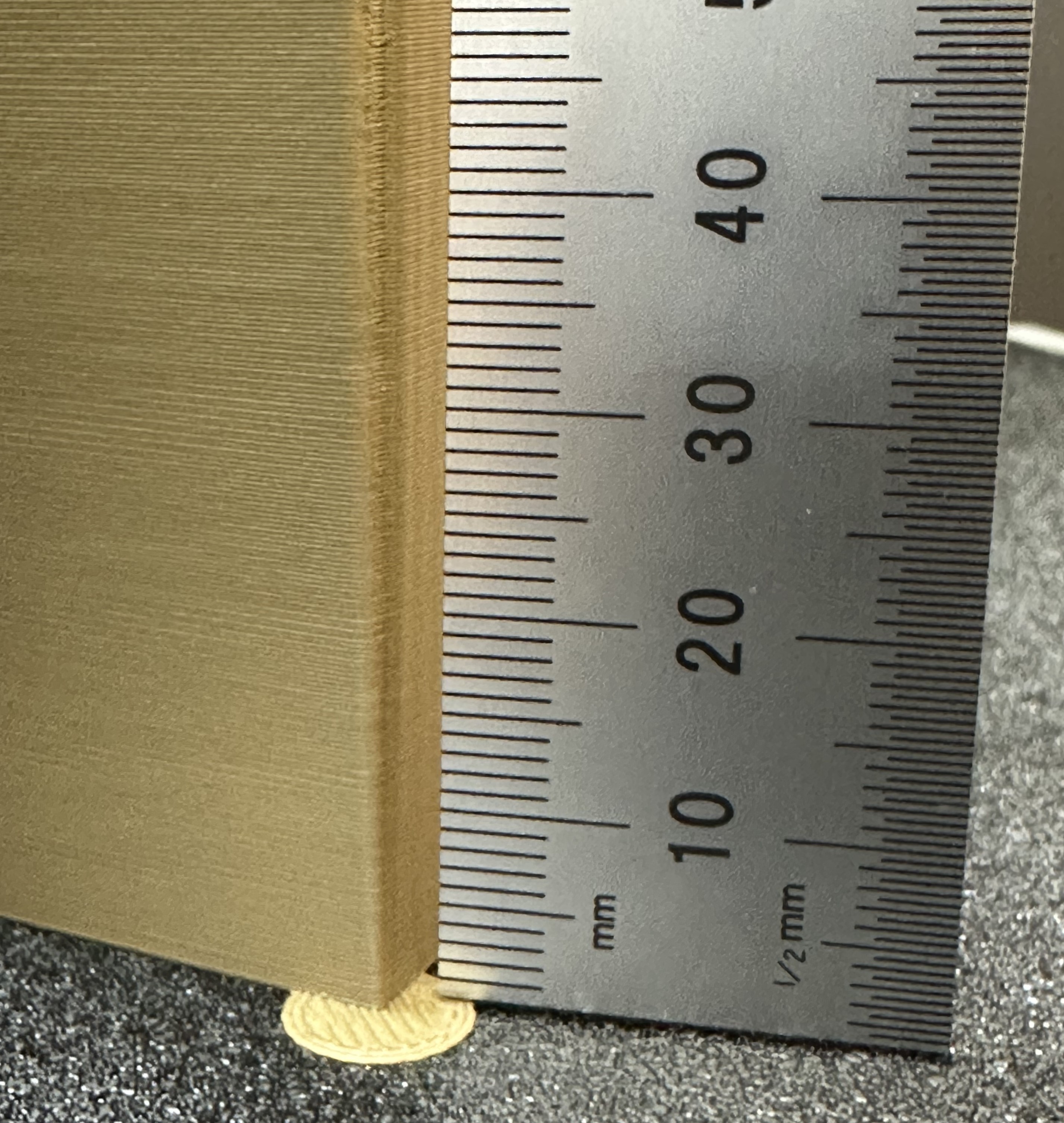

The tower method may take a bit more time to complete, but it does not rely on the quality of the first layer.

|

||||

The PA value for this test will be increased by 0.002 for every 1 mm increase in height. (**NOTE** 0.02 for Bowden)

|

||||

The tower method may take a bit more time to complete, but it does not rely on the quality of the first layer.

|

||||

The PA value for this test will be increased by 0.002 for every 1 mm increase in height. (**NOTE** 0.02 for Bowden)

|

||||

Steps:

|

||||

1. Select the printer, filament, and process you would like to use for the test.

|

||||

2. Examine each corner of the print and mark the height that yields the best overall result.

|

||||

|

|

@ -117,37 +117,37 @@ Steps:

|

|||

|

||||

|

||||

|

||||

# Temp tower

|

||||

|

||||

Temp tower is a straightforward test. The temp tower is a vertical tower with multiple blocks, each printed at a different temperature. Once the print is complete, we can examine each block of the tower and determine the optimal temperature for the filament. The optimal temperature is the one that produces the highest quality print with the least amount of issues, such as stringing, layer adhesion, warping (overhang), and bridging.

|

||||

|

||||

# Temp tower

|

||||

|

||||

Temp tower is a straightforward test. The temp tower is a vertical tower with multiple blocks, each printed at a different temperature. Once the print is complete, we can examine each block of the tower and determine the optimal temperature for the filament. The optimal temperature is the one that produces the highest quality print with the least amount of issues, such as stringing, layer adhesion, warping (overhang), and bridging.

|

||||

|

||||

|

||||

# Retraction test

|

||||

|

||||

This test generates a retraction tower automatically. The retraction tower is a vertical structure with multiple notches, each printed at a different retraction length. After the print is complete, we can examine each section of the tower to determine the optimal retraction length for the filament. The optimal retraction length is the shortest one that produces the cleanest tower.

|

||||

|

||||

|

||||

This test generates a retraction tower automatically. The retraction tower is a vertical structure with multiple notches, each printed at a different retraction length. After the print is complete, we can examine each section of the tower to determine the optimal retraction length for the filament. The optimal retraction length is the shortest one that produces the cleanest tower.

|

||||

|

||||

In the dialog, you can select the start and end retraction length, as well as the retraction length increment step. The default values are 0mm for the start retraction length, 2mm for the end retraction length, and 0.1mm for the step. These values are suitable for most direct drive extruders. However, for Bowden extruders, you may want to increase the start and end retraction lengths to 1mm and 6mm, respectively, and set the step to 0.2mm.

|

||||

|

||||

**Note**: When testing filaments such as PLA or ABS that have minimal oozing, the retraction settings can be highly effective. You may find that the retraction tower appears clean right from the start. In such situations, setting the retraction length to 0.2mm - 0.4mm using Orca Slicer should suffice.

|

||||

On the other hand, if there is still a lot of stringing at the top of the tower, it is recommended to dry your filament and ensure that your nozzle is properly installed without any leaks.

|

||||

|

||||

On the other hand, if there is still a lot of stringing at the top of the tower, it is recommended to dry your filament and ensure that your nozzle is properly installed without any leaks.

|

||||

|

||||

|

||||

# Orca Tolerance Test

|

||||

This tolerance test is specifically designed to assess the dimensional accuracy of your printer and filament. The model comprises a base and a hexagon tester. The base contains six hexagon hole, each with a different tolerance: 0.0mm, 0.05mm, 0.1mm, 0.2mm, 0.3mm, and 0.4mm. The dimensions of the hexagon tester are illustrated in the image.

|

||||

|

||||

This tolerance test is specifically designed to assess the dimensional accuracy of your printer and filament. The model comprises a base and a hexagon tester. The base contains six hexagon hole, each with a different tolerance: 0.0mm, 0.05mm, 0.1mm, 0.2mm, 0.3mm, and 0.4mm. The dimensions of the hexagon tester are illustrated in the image.

|

||||

|

||||

|

||||

You can assess the tolerance using either an M6 Allen key or the printed hexagon tester.

|

||||

|

||||

|

||||

You can assess the tolerance using either an M6 Allen key or the printed hexagon tester.

|

||||

|

||||

|

||||

|

||||

# Advanced Calibration

|

||||

|

||||

## Max Volumetric speed

|

||||

This is a test designed to calibrate the maximum volumetric speed of the specific filament. The generic or 3rd party filament types may not have the correct volumetric flow rate set in the filament. This test will help you to find the maximum volumetric speed of the filament.

|

||||

|

||||

You will be promted to enter the settings for the test: start volumetric speed, end volumentric speed, and step. It is recommended to use the default values (5mm³/s start, 20mm³/s end, with a step of 0.5), unless you already have an idea of the lower or upper limit for your filament. Select "OK", slice the plate, and send it to the printer.

|

||||

You will be promted to enter the settings for the test: start volumetric speed, end volumentric speed, and step. It is recommended to use the default values (5mm³/s start, 20mm³/s end, with a step of 0.5), unless you already have an idea of the lower or upper limit for your filament. Select "OK", slice the plate, and send it to the printer.

|

||||

|

||||

Once printed, take note of where the layers begin to fail and where the quality begins to suffer. Pay attention to changes from matte to shiny as well.

|

||||

Once printed, take note of where the layers begin to fail and where the quality begins to suffer. Pay attention to changes from matte to shiny as well.

|

||||

|

||||

|

||||

|

||||

|

|

@ -155,7 +155,7 @@ Using calipers or a ruler, measure the height of the print at that point. Use th

|

|||

|

||||

|

||||

|

||||

You can also return to OrcaSlicer in the "Preview" tab, make sure the color scheme "flow" is selected. Scroll down to the layer height that you measured, and click on the toolhead slider. This will indicate the max flow level for your filmanet.

|

||||

You can also return to OrcaSlicer in the "Preview" tab, make sure the color scheme "flow" is selected. Scroll down to the layer height that you measured, and click on the toolhead slider. This will indicate the max flow level for your filmanet.

|

||||

|

||||

|

||||

|

||||

|

|

@ -176,13 +176,15 @@ Ussualy the recommended values modes are ``MZV`` or ``EI`` for Delta printers.

|

|||

1. Pre-requisites:

|

||||

1. In OrcaSlicer, set:

|

||||

1. Acceleration high enough to trigger ringing (e.g., 2000 mm/s²).

|

||||

2. Speed high enough to trigger ringing (e.g., 100 mm/s).

|

||||

2. Speed high enough to trigger ringing (e.g., 200 mm/s).

|

||||

> [!NOTE]

|

||||

> These settings depend on your printer's motion ability and the filament's max volumetric speed. If you can't reach speeds that cause ringing, try increasing the filament's max volumetric speed (avoid materials below 10 mm³/s).

|

||||

3. Jerk [Klipper Square Corner Velocity](https://www.klipper3d.org/Kinematics.html?h=square+corner+velocity#look-ahead) to 5 or a high value (e.g., 20).

|

||||

2. In printer settigs:

|

||||

1. Set the Shaper Type to ``MZV`` or ``EI``.

|

||||

```

|

||||

SET_INPUT_SHAPER SHAPER_TYPE=MZV

|

||||

```

|

||||

```

|

||||

2. Disable [Minimun Cruise Ratio](https://www.klipper3d.org/Kinematics.html#minimum-cruise-ratio) with:

|

||||

```

|

||||

SET_VELOCITY_LIMIT MINIMUM_CRUISE_RATIO=0

|

||||

|

|

@ -198,14 +200,14 @@ Ussualy the recommended values modes are ``MZV`` or ``EI`` for Delta printers.

|

|||

|

||||

|

||||

2. If not a clear result, you can measure a X and Y min and max acceptable heights and repeat the test with that min and max value.

|

||||

|

||||

|

||||

**Note**: There is a chance you will need to set higher than 60Hz frequencies. Some printers with very rigid frames and excellent mechanics may exhibit frequencies exceeding 100Hz.

|

||||

3. Print the Damping test setting your X and Y frequency to the value you found in the previous step.

|

||||

|

||||

|

||||

|

||||

1. Measure the X and Y heights and read the damping set at that point in Orca Slicer.

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

|

|

@ -223,12 +225,14 @@ ZV Input Shaping introduces an anti-vibration signal into the stepper motion for

|

|||

1. Pre-requisites:

|

||||

1. In OrcaSlicer, set:

|

||||

1. Acceleration high enough to trigger ringing (e.g., 2000 mm/s²).

|

||||

2. Speed high enough to trigger ringing (e.g., 100 mm/s).

|

||||

3. Jerk

|

||||

2. Speed high enough to trigger ringing (e.g., 200 mm/s).

|

||||

> [!NOTE]

|

||||

> These settings depend on your printer's motion ability and the filament's max volumetric speed. If you can't reach speeds that cause ringing, try increasing the filament's max volumetric speed (avoid materials below 10 mm³/s).

|

||||

4. Jerk

|

||||

1. If using [Classic Jerk](https://marlinfw.org/docs/configuration/configuration.html#jerk-) use a high value (e.g., 20).

|

||||

2. If using [Junction Deviation](https://marlinfw.org/docs/features/junction_deviation.html) (new Marlin default mode) this test will use 0.25 (high enough to most printers).

|

||||

2. Use an opaque, high-gloss filament to make the ringing more visible.

|

||||

2. Print the Input Shaping Frequency test with a range of frequencies.

|

||||

2. Print the Input Shaping Frequency test with a range of frequencies.

|

||||

|

||||

|

||||

|

||||

|

|

@ -238,7 +242,7 @@ ZV Input Shaping introduces an anti-vibration signal into the stepper motion for

|

|||

|

||||

|

||||

2. If not a clear result, you can measure a X and Y min and max acceptable heights and repeat the test with that min and max value.

|

||||

|

||||

|

||||

**Note**: There is a chance you will need to set higher than 60Hz frequencies. Some printers with very rigid frames and excellent mechanics may exhibit frequencies exceeding 100Hz.

|

||||

3. Print the Damping test setting your X and Y frequency to the value you found in the previous step.

|

||||

|

||||

|

|

@ -287,20 +291,20 @@ The default value in Marlin is typically set to 0.08mm, which may be too high fo

|

|||

2. Speed high enough to trigger ringing (e.g., 100 mm/s).

|

||||

3. Use an opaque, high-gloss filament to make the ringing more visible.

|

||||

2. You need to print the Junction Deviation test.

|

||||

|

||||

|

||||

|

||||

|

||||

1. Measure the X and Y heights and read the frequency set at that point in Orca Slicer.

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

2. It’s very likely that you’ll need to set values lower than 0.08 mm, as shown in the previous example. To determine a more accurate maximum JD value, you can print a new calibration tower with a maximum value set at the point where the corners start losing sharpness.

|

||||

3.

|

||||

3.

|

||||

|

||||

|

||||

4. Measure the X and Y heights and read the frequency set at that point in Orca Slicer.

|

||||

|

||||

|

||||

|

||||

|

||||

3. Save the settings

|

||||

|

|

@ -332,7 +336,7 @@ Because of the nature of these artifacts the methods to reduce them can be mecha

|

|||

|

||||

|

||||

***

|

||||

*Credits:*

|

||||

*Credits:*

|

||||

- *The Flowrate test and retraction test is inspired by [SuperSlicer](https://github.com/supermerill/SuperSlicer).*

|

||||

- *The PA Line method is inspired by [K-factor Calibration Pattern](https://marlinfw.org/tools/lin_advance/k-factor.html).*

|

||||

- *The PA Tower method is inspired by [Klipper](https://www.klipper3d.org/Pressure_Advance.html).*

|

||||

|

|

|

|||

|

Before Width: | Height: | Size: 8.7 KiB After Width: | Height: | Size: 8.7 KiB |

|

|

@ -50,7 +50,8 @@

|

|||

],

|

||||

"gcode_flavor": "klipper",

|

||||

"change_filament_gcode": "M600",

|

||||

"layer_change_gcode": "SET_PRINT_STATS_INFO CURRENT_LAYER={layer_num + 1}",

|

||||

"machine_pause_gcode": "M600",

|

||||

"machine_start_gcode": ";;===== date: 20240520 =====================\n;printer_model:[printer_model]\n;initial_filament:{filament_type[initial_extruder]}\n;curr_bed_type:{curr_bed_type}\nM400 ; wait for buffer to clear\nM220 S100 ;Set the feed speed to 100%\nM221 S100 ;Set the flow rate to 100%\nM104 S140\nM190 S[bed_temperature_initial_layer_single]\nG90\nG28 ;home\nM729 ;Clean Nozzle\n\n\n;=============turn on fans to prevent PLA jamming=================\n{if filament_type[initial_no_support_extruder]==\"PLA\"}\n {if (bed_temperature[initial_no_support_extruder] >50)||(bed_temperature_initial_layer[initial_no_support_extruder] >50)}\n M106 P3 S255\n {elsif (bed_temperature[initial_no_support_extruder] >45)||(bed_temperature_initial_layer[initial_no_support_extruder] >45)}\n M106 P3 S180\n {endif};Prevent PLA from jamming\n{endif}\n\n;enable_pressure_advance:{enable_pressure_advance[initial_extruder]}\n;This value is called if pressure advance is enabled\n{if enable_pressure_advance[initial_extruder] == \"true\"}\nSET_PRESSURE_ADVANCE ADVANCE=[pressure_advance] ;\nM400\n{endif}\nM204 S{min(20000,max(1000,outer_wall_acceleration))} ;Call exterior wall print acceleration\n\n\nG1 X{print_bed_max[0]*0.5} Y-1.2 F20000\nG1 Z0.3 F900\nM109 S[nozzle_temperature_initial_layer]\nM83\nG92 E0 ;Reset Extruder\nG1 F{min(6000, max(900, filament_max_volumetric_speed[initial_no_support_extruder]/0.5/0.3*60))} \nG1 X-1.2 E10.156 ;Draw the first line\nG1 Y98.8 E7.934\nG1 X-0.5 Y100 E0.1\nG1 Y-0.3 E7.934\nG1 X{print_bed_max[0]*0.5-50} E6.284\nG1 F{0.2*min(12000, max(1200, filament_max_volumetric_speed[initial_no_support_extruder]/0.5/0.3*60))} \nG1 X{print_bed_max[0]*0.5-30} E2\nG1 F{min(12000, max(1200, filament_max_volumetric_speed[initial_no_support_extruder]/0.5/0.3*60))} \nG1 X{print_bed_max[0]*0.5-10} E2\nG1 F{0.2*min(12000, max(1200, filament_max_volumetric_speed[initial_no_support_extruder]/0.5/0.3*60))} \nG1 X{print_bed_max[0]*0.5+10} E2\nG1 F{min(12000, max(1200, filament_max_volumetric_speed[initial_no_support_extruder]/0.5/0.3*60))} \nG1 X{print_bed_max[0]*0.5+30} E2\nG1 F{min(12000, max(1200, filament_max_volumetric_speed[initial_no_support_extruder]/0.5/0.3*60))} \nG1 X{print_bed_max[0]*0.5+50} E2\n;End PA test.\n\n\nG3 I-1 J0 Z0.6 F1200.0 ;Move to side a little\nG1 F20000\nG92 E0 ;Reset Extruder\n;LAYER_COUNT:[total_layer_count]\n;LAYER:0",

|

||||

"machine_start_gcode": ";;===== date: 20240520 =====================\n;printer_model:[printer_model]\n;initial_filament:{filament_type[initial_extruder]}\n;curr_bed_type:{curr_bed_type}\nM400 ; wait for buffer to clear\nM220 S100 ;Set the feed speed to 100%\nM221 S100 ;Set the flow rate to 100%\nM104 S140\nM140 S[bed_temperature_initial_layer_single]\nG90\nG28 ;home\nM729 ;Clean Nozzle\nM106 P2 S255\nM190 S[bed_temperature_initial_layer_single]\nM106 P2 S0\n\n\n;=============turn on fans to prevent PLA jamming=================\n{if filament_type[initial_no_support_extruder]==\"PLA\"}\n {if (bed_temperature[initial_no_support_extruder] >50)||(bed_temperature_initial_layer[initial_no_support_extruder] >50)}\n M106 P3 S255\n {elsif (bed_temperature[initial_no_support_extruder] >45)||(bed_temperature_initial_layer[initial_no_support_extruder] >45)}\n M106 P3 S180\n {endif};Prevent PLA from jamming\n{endif}\n\n;enable_pressure_advance:{enable_pressure_advance[initial_extruder]}\n;This value is called if pressure advance is enabled\n{if enable_pressure_advance[initial_extruder] == \"true\"}\nSET_PRESSURE_ADVANCE ADVANCE=[pressure_advance] ;\nM400\n{endif}\nM204 S{min(20000,max(1000,outer_wall_acceleration))} ;Call exterior wall print acceleration\n\n\nG1 X{print_bed_max[0]*0.5} Y-1.2 F20000\nG1 Z0.3 F900\nM109 S[nozzle_temperature_initial_layer]\nM83\nG92 E0 ;Reset Extruder\nG1 F{min(6000, max(900, filament_max_volumetric_speed[initial_no_support_extruder]/0.5/0.3*60))} \nG1 X-1.2 E10.156 ;Draw the first line\nG1 Y98.8 E7.934\nG1 X-0.5 Y100 E0.1\nG1 Y-0.3 E7.934\nG1 X{print_bed_max[0]*0.5-50} E6.284\nG1 F{0.2*min(12000, max(1200, filament_max_volumetric_speed[initial_no_support_extruder]/0.5/0.3*60))} \nG1 X{print_bed_max[0]*0.5-30} E2\nG1 F{min(12000, max(1200, filament_max_volumetric_speed[initial_no_support_extruder]/0.5/0.3*60))} \nG1 X{print_bed_max[0]*0.5-10} E2\nG1 F{0.2*min(12000, max(1200, filament_max_volumetric_speed[initial_no_support_extruder]/0.5/0.3*60))} \nG1 X{print_bed_max[0]*0.5+10} E2\nG1 F{min(12000, max(1200, filament_max_volumetric_speed[initial_no_support_extruder]/0.5/0.3*60))} \nG1 X{print_bed_max[0]*0.5+30} E2\nG1 F{min(12000, max(1200, filament_max_volumetric_speed[initial_no_support_extruder]/0.5/0.3*60))} \nG1 X{print_bed_max[0]*0.5+50} E2\n;End PA test.\n\n\nG3 I-1 J0 Z0.6 F1200.0 ;Move to side a little\nG1 F20000\nG92 E0 ;Reset Extruder\nSET_PRINT_STATS_INFO TOTAL_LAYER=[total_layer_count]\n;LAYER_COUNT:[total_layer_count]\n;LAYER:0",

|

||||

"machine_end_gcode": ";===== date: 20250109 =====================\nM400 ; wait for buffer to clear\nM140 S0 ;Turn-off bed\nM106 S255 ;Cooling nozzle\nM83\nG92 E0 ; zero the extruder\nG2 I1 J0 Z{max_layer_z+0.5} E-1 F3000 ; lower z a little\nG90\n{if max_layer_z > 50}G1 Z{min(max_layer_z+50, printable_height+0.5)} F20000{else}G1 Z100 F20000 {endif}; Move print head up \nM204 S5000\nM400\nM83\nG1 X202 F20000\nM400\nG1 Y250 F20000\nG1 Y264.5 F1200\nM400\nG92 E0\nM104 S0 ;Turn-off hotend\nM140 S0 ;Turn-off bed\nM106 S0 ; turn off fan\nM106 P2 S0 ; turn off remote part cooling fan\nM106 P3 S0 ; turn off chamber cooling fan\nM84 ;Disable all steppers"

|

||||

}

|

||||

}

|

||||

|

|

|

|||

|

|

@ -52,6 +52,6 @@

|

|||

"change_filament_gcode": "M600",

|

||||

"layer_change_gcode": "SET_PRINT_STATS_INFO CURRENT_LAYER={layer_num + 1}",

|

||||

"machine_pause_gcode": "M600",

|

||||

"machine_start_gcode": ";;===== date: 20240520 =====================\n;printer_model:[printer_model]\n;initial_filament:{filament_type[initial_extruder]}\n;curr_bed_type:{curr_bed_type}\nM400 ; wait for buffer to clear\nM220 S100 ;Set the feed speed to 100%\nM221 S100 ;Set the flow rate to 100%\nM104 S140\nM190 S[bed_temperature_initial_layer_single]\nG90\nG28 ;home\nM729 ;Clean Nozzle\n\n\n;=============turn on fans to prevent PLA jamming=================\n{if filament_type[initial_no_support_extruder]==\"PLA\"}\n {if (bed_temperature[initial_no_support_extruder] >50)||(bed_temperature_initial_layer[initial_no_support_extruder] >50)}\n M106 P3 S255\n {elsif (bed_temperature[initial_no_support_extruder] >45)||(bed_temperature_initial_layer[initial_no_support_extruder] >45)}\n M106 P3 S180\n {endif};Prevent PLA from jamming\n{endif}\n\n;enable_pressure_advance:{enable_pressure_advance[initial_extruder]}\n;This value is called if pressure advance is enabled\n{if enable_pressure_advance[initial_extruder] == \"true\"}\nSET_PRESSURE_ADVANCE ADVANCE=[pressure_advance] ;\nM400\n{endif}\nM204 S{min(20000,max(1000,outer_wall_acceleration))} ;Call exterior wall print acceleration\n\n\nG1 X{print_bed_max[0]*0.5} Y-1.2 F20000\nG1 Z0.3 F900\nM109 S[nozzle_temperature_initial_layer]\nM83\nG92 E0 ;Reset Extruder\nG1 F{min(6000, max(900, filament_max_volumetric_speed[initial_no_support_extruder]/0.5/0.3*60))} \nG1 X-1.2 E10.156 ;Draw the first line\nG1 Y98.8 E7.934\nG1 X-0.5 Y100 E0.1\nG1 Y-0.3 E7.934\nG1 X{print_bed_max[0]*0.5-50} E6.284\nG1 F{0.2*min(12000, max(1200, filament_max_volumetric_speed[initial_no_support_extruder]/0.5/0.3*60))} \nG1 X{print_bed_max[0]*0.5-30} E2\nG1 F{min(12000, max(1200, filament_max_volumetric_speed[initial_no_support_extruder]/0.5/0.3*60))} \nG1 X{print_bed_max[0]*0.5-10} E2\nG1 F{0.2*min(12000, max(1200, filament_max_volumetric_speed[initial_no_support_extruder]/0.5/0.3*60))} \nG1 X{print_bed_max[0]*0.5+10} E2\nG1 F{min(12000, max(1200, filament_max_volumetric_speed[initial_no_support_extruder]/0.5/0.3*60))} \nG1 X{print_bed_max[0]*0.5+30} E2\nG1 F{min(12000, max(1200, filament_max_volumetric_speed[initial_no_support_extruder]/0.5/0.3*60))} \nG1 X{print_bed_max[0]*0.5+50} E2\n;End PA test.\n\n\nG3 I-1 J0 Z0.6 F1200.0 ;Move to side a little\nG1 F20000\nG92 E0 ;Reset Extruder\nSET_PRINT_STATS_INFO TOTAL_LAYER=[total_layer_count]\n;LAYER_COUNT:[total_layer_count]\n;LAYER:0",

|

||||

"machine_start_gcode": ";;===== date: 20240520 =====================\n;printer_model:[printer_model]\n;initial_filament:{filament_type[initial_extruder]}\n;curr_bed_type:{curr_bed_type}\nM400 ; wait for buffer to clear\nM220 S100 ;Set the feed speed to 100%\nM221 S100 ;Set the flow rate to 100%\nM104 S140\nM140 S[bed_temperature_initial_layer_single]\nG90\nG28 ;home\nM729 ;Clean Nozzle\nM106 P2 S255\nM190 S[bed_temperature_initial_layer_single]\nM106 P2 S0\n\n\n;=============turn on fans to prevent PLA jamming=================\n{if filament_type[initial_no_support_extruder]==\"PLA\"}\n {if (bed_temperature[initial_no_support_extruder] >50)||(bed_temperature_initial_layer[initial_no_support_extruder] >50)}\n M106 P3 S255\n {elsif (bed_temperature[initial_no_support_extruder] >45)||(bed_temperature_initial_layer[initial_no_support_extruder] >45)}\n M106 P3 S180\n {endif};Prevent PLA from jamming\n{endif}\n\n;enable_pressure_advance:{enable_pressure_advance[initial_extruder]}\n;This value is called if pressure advance is enabled\n{if enable_pressure_advance[initial_extruder] == \"true\"}\nSET_PRESSURE_ADVANCE ADVANCE=[pressure_advance] ;\nM400\n{endif}\nM204 S{min(20000,max(1000,outer_wall_acceleration))} ;Call exterior wall print acceleration\n\n\nG1 X{print_bed_max[0]*0.5} Y-1.2 F20000\nG1 Z0.3 F900\nM109 S[nozzle_temperature_initial_layer]\nM83\nG92 E0 ;Reset Extruder\nG1 F{min(6000, max(900, filament_max_volumetric_speed[initial_no_support_extruder]/0.5/0.3*60))} \nG1 X-1.2 E10.156 ;Draw the first line\nG1 Y98.8 E7.934\nG1 X-0.5 Y100 E0.1\nG1 Y-0.3 E7.934\nG1 X{print_bed_max[0]*0.5-50} E6.284\nG1 F{0.2*min(12000, max(1200, filament_max_volumetric_speed[initial_no_support_extruder]/0.5/0.3*60))} \nG1 X{print_bed_max[0]*0.5-30} E2\nG1 F{min(12000, max(1200, filament_max_volumetric_speed[initial_no_support_extruder]/0.5/0.3*60))} \nG1 X{print_bed_max[0]*0.5-10} E2\nG1 F{0.2*min(12000, max(1200, filament_max_volumetric_speed[initial_no_support_extruder]/0.5/0.3*60))} \nG1 X{print_bed_max[0]*0.5+10} E2\nG1 F{min(12000, max(1200, filament_max_volumetric_speed[initial_no_support_extruder]/0.5/0.3*60))} \nG1 X{print_bed_max[0]*0.5+30} E2\nG1 F{min(12000, max(1200, filament_max_volumetric_speed[initial_no_support_extruder]/0.5/0.3*60))} \nG1 X{print_bed_max[0]*0.5+50} E2\n;End PA test.\n\n\nG3 I-1 J0 Z0.6 F1200.0 ;Move to side a little\nG1 F20000\nG92 E0 ;Reset Extruder\nSET_PRINT_STATS_INFO TOTAL_LAYER=[total_layer_count]\n;LAYER_COUNT:[total_layer_count]\n;LAYER:0",

|

||||

"machine_end_gcode": ";===== date: 20250109 =====================\nM400 ; wait for buffer to clear\nM140 S0 ;Turn-off bed\nM106 S255 ;Cooling nozzle\nM83\nG92 E0 ; zero the extruder\nG2 I1 J0 Z{max_layer_z+0.5} E-1 F3000 ; lower z a little\nG90\n{if max_layer_z > 50}G1 Z{min(max_layer_z+50, printable_height+0.5)} F20000{else}G1 Z100 F20000 {endif}; Move print head up \nM204 S5000\nM400\nM83\nG1 X202 F20000\nM400\nG1 Y250 F20000\nG1 Y264.5 F1200\nM400\nG92 E0\nM104 S0 ;Turn-off hotend\nM140 S0 ;Turn-off bed\nM106 S0 ; turn off fan\nM106 P2 S0 ; turn off remote part cooling fan\nM106 P3 S0 ; turn off chamber cooling fan\nM84 ;Disable all steppers"

|

||||

}

|

||||

|

|

|

|||

|

|

@ -5,7 +5,6 @@

|

|||

"reduce_crossing_wall": "1",

|

||||

"bottom_shell_layers": "5",

|

||||

"outer_wall_speed": "120",

|

||||

"print_flow_ratio": "0.95",

|

||||

"sparse_infill_density": "20%",

|

||||

"top_shell_layers": "6",

|

||||

"wall_loops": "6",

|

||||

|

|

|

|||

|

|

@ -5,7 +5,6 @@

|

|||

"reduce_crossing_wall": "1",

|

||||

"bottom_shell_layers": "5",

|

||||

"outer_wall_speed": "120",

|

||||

"print_flow_ratio": "0.95",

|

||||

"sparse_infill_density": "20%",

|

||||

"top_shell_layers": "6",

|

||||

"wall_loops": "6",

|

||||

|

|

|

|||

|

|

@ -88,6 +88,6 @@

|

|||

"wipe_before_external_loop": "0",

|

||||

"exclude_object": "1",

|

||||

"wipe_speed": "100%",

|

||||

"print_flow_ratio": "0.97",

|

||||

"print_flow_ratio": "1.0",

|

||||

"wall_sequence": "inner wall/outer wall"

|

||||

}

|

||||

|

|

|

|||

|

|

@ -11,7 +11,7 @@

|

|||

"printer_variant": "0.25",

|

||||

"max_layer_height": ["0.14"],

|

||||

"min_layer_height": ["0.08"],

|

||||

"machine_start_gcode": "M190 S[bed_temperature_initial_layer_single]\nM104 S[nozzle_temperature_initial_layer]\nG1 Z5 F6000\nG90 E0\nM83\nG1 E-1 F600\nG1 E8 F300\nG1 X85 Y110 Z0.2 F1200\nG1 X-110 E15 F2400\nG1 Y0 E4 F2400\nG1 X-109.6 F2400\nG1 Y110 E5 F2400\nG92 E0",

|

||||

"machine_start_gcode": "M190 S[bed_temperature_initial_layer_single]\nM104 S[nozzle_temperature_initial_layer]\nG90\nM83\nG1 Z5 F6000\nG90 E0\nM83\nG1 E-1 F600\nG1 E8 F300\nG1 X85 Y110 Z0.2 F1200\nG1 X-110 E15 F2400\nG1 Y0 E4 F2400\nG1 X-109.6 F2400\nG1 Y110 E5 F2400\nG92 E0",

|

||||

"retraction_length": ["1"],

|

||||

"z_hop": ["0.3"],

|

||||

"nozzle_type": "stainless_steel"

|

||||

|

|

|

|||

|

|

@ -9,7 +9,7 @@

|

|||

"default_print_profile": "0.40mm Standard @Flashforge AD5M 0.8 Nozzle",

|

||||

"nozzle_diameter": ["0.8"],

|

||||

"printer_variant": "0.8",

|

||||

"machine_start_gcode": "M190 S[bed_temperature_initial_layer_single]\nM104 S[nozzle_temperature_initial_layer]\nG1 Z5 F6000\nG1 E-1.5 F600\nG1 E12 F800\nG1 X85 Y110 Z0.3 F1200\nG1 X-110 E30 F2400\nG1 Y0 E8 F2400\nG1 X-109.6 F2400\nG1 Y110 E10 F2400\nG92 E0",

|

||||

"machine_start_gcode": "M190 S[bed_temperature_initial_layer_single]\nM104 S[nozzle_temperature_initial_layer]\nG90\nM83\nG1 Z5 F6000\nG1 E-1.5 F600\nG1 E12 F800\nG1 X85 Y110 Z0.3 F1200\nG1 X-110 E30 F2400\nG1 Y0 E8 F2400\nG1 X-109.6 F2400\nG1 Y110 E10 F2400\nG92 E0",

|

||||

"max_layer_height": ["0.56"],

|

||||

"min_layer_height": ["0.24"],

|

||||

"retraction_length": ["1.5"],

|

||||

|

|

|

|||

|

|

@ -11,7 +11,7 @@

|

|||

"printer_variant": "0.25",

|

||||

"max_layer_height": ["0.14"],

|

||||

"min_layer_height": ["0.08"],

|

||||

"machine_start_gcode": "M190 S[bed_temperature_initial_layer_single]\nM104 S[nozzle_temperature_initial_layer]\nG1 Z5 F6000\nG90 E0\nM83\nG1 E-1 F600\nG1 E8 F300\nG1 X85 Y110 Z0.2 F1200\nG1 X-110 E15 F2400\nG1 Y0 E4 F2400\nG1 X-109.6 F2400\nG1 Y110 E5 F2400\nG92 E0",

|

||||

"machine_start_gcode": "M190 S[bed_temperature_initial_layer_single]\nM104 S[nozzle_temperature_initial_layer]\nG90\nM83\nG1 Z5 F6000\nG90 E0\nM83\nG1 E-1 F600\nG1 E8 F300\nG1 X85 Y110 Z0.2 F1200\nG1 X-110 E15 F2400\nG1 Y0 E4 F2400\nG1 X-109.6 F2400\nG1 Y110 E5 F2400\nG92 E0",

|

||||

"retraction_length": ["1"],

|

||||

"z_hop": ["0.3"],

|

||||

"nozzle_type": "stainless_steel"

|

||||

|

|

|

|||

|

|

@ -9,7 +9,7 @@

|

|||

"default_print_profile": "0.40mm Standard @Flashforge AD5M Pro 0.8 Nozzle",

|

||||

"nozzle_diameter": ["0.8"],

|

||||

"printer_variant": "0.8",

|

||||

"machine_start_gcode": "M190 S[bed_temperature_initial_layer_single]\nM104 S[nozzle_temperature_initial_layer]\nG1 Z5 F6000\nG1 E-1.5 F600\nG1 E12 F800\nG1 X85 Y110 Z0.3 F1200\nG1 X-110 E30 F2400\nG1 Y0 E8 F2400\nG1 X-109.6 F2400\nG1 Y110 E10 F2400\nG92 E0",

|

||||

"machine_start_gcode": "M190 S[bed_temperature_initial_layer_single]\nM104 S[nozzle_temperature_initial_layer]\nG90\nM83\nG1 Z5 F6000\nG1 E-1.5 F600\nG1 E12 F800\nG1 X85 Y110 Z0.3 F1200\nG1 X-110 E30 F2400\nG1 Y0 E8 F2400\nG1 X-109.6 F2400\nG1 Y110 E10 F2400\nG92 E0",

|

||||

"max_layer_height": ["0.56"],

|

||||

"min_layer_height": ["0.24"],

|

||||

"retraction_length": ["1.5"],

|

||||

|

|

|

|||

Binary file not shown.

|

|

@ -23,7 +23,7 @@ void FillLine::_fill_surface_single(

|

|||

this->_diagonal_distance = this->_line_spacing * 2;

|

||||

this->_line_oscillation = this->_line_spacing - this->_min_spacing; // only for Line infill

|

||||

BoundingBox bounding_box = expolygon.contour.bounding_box();

|

||||

|

||||

|

||||

// define flow spacing according to requested density

|

||||

if (params.density > 0.9999f && !params.dont_adjust) {

|

||||

this->_line_spacing = this->_adjust_solid_spacing(bounding_box.size()(0), this->_line_spacing);

|

||||

|

|

@ -32,8 +32,8 @@ void FillLine::_fill_surface_single(

|

|||

// extend bounding box so that our pattern will be aligned with other layers

|

||||

// Transform the reference point to the rotated coordinate system.

|

||||

bounding_box.merge(align_to_grid(

|

||||

bounding_box.min,

|

||||

Point(this->_line_spacing, this->_line_spacing),

|

||||

bounding_box.min,

|

||||

Point(this->_line_spacing, this->_line_spacing),

|

||||

direction.second.rotated(- direction.first)));

|

||||

}

|

||||

|

||||

|

|

@ -46,7 +46,7 @@ void FillLine::_fill_surface_single(

|

|||

// clip paths against a slightly larger expolygon, so that the first and last paths

|

||||

// are kept even if the expolygon has vertical sides

|

||||

// the minimum offset for preventing edge lines from being clipped is SCALED_EPSILON;

|

||||

// however we use a larger offset to support expolygons with slightly skewed sides and

|

||||

// however we use a larger offset to support expolygons with slightly skewed sides and

|

||||

// not perfectly straight

|

||||

//FIXME Vojtech: Update the intersecton function to work directly with lines.

|

||||

Polylines polylines_src;

|

||||

|

|

@ -76,7 +76,7 @@ void FillLine::_fill_surface_single(

|

|||

size_t n_polylines_out_old = polylines_out.size();

|

||||

|

||||

// connect lines

|

||||

if (! params.dont_connect() && ! polylines.empty()) { // prevent calling leftmost_point() on empty collections

|

||||

if (! polylines.empty()) { // prevent calling leftmost_point() on empty collections

|

||||

// offset the expolygon by max(min_spacing/2, extra)

|

||||

ExPolygon expolygon_off;

|

||||

{

|

||||

|

|

@ -96,9 +96,9 @@ void FillLine::_fill_surface_single(

|

|||

const Point &last_point = pts_end.back();

|

||||

// Distance in X, Y.

|

||||

const Vector distance = last_point - first_point;

|

||||

// TODO: we should also check that both points are on a fill_boundary to avoid

|

||||

// TODO: we should also check that both points are on a fill_boundary to avoid

|

||||

// connecting paths on the boundaries of internal regions

|

||||

if (this->_can_connect(std::abs(distance(0)), std::abs(distance(1))) &&

|

||||

if (this->_can_connect(std::abs(distance(0)), std::abs(distance(1))) &&

|

||||

expolygon_off.contains(Line(last_point, first_point))) {

|

||||

// Append the polyline.

|

||||

pts_end.insert(pts_end.end(), polyline.points.begin(), polyline.points.end());

|

||||

|

|

|

|||

|

|

@ -548,19 +548,11 @@ std::vector<size_t> Print::layers_sorted_for_object(float start, float end, std:

|

|||

StringObjectException Print::sequential_print_clearance_valid(const Print &print, Polygons *polygons, std::vector<std::pair<Polygon, float>>* height_polygons)

|

||||

{

|

||||

StringObjectException single_object_exception;

|

||||

auto print_config = print.config();

|

||||

Pointfs excluse_area_points = print_config.bed_exclude_area.values;

|

||||

Polygons exclude_polys;

|

||||

Polygon exclude_poly;

|

||||

const auto& print_config = print.config();

|

||||

Polygons exclude_polys = get_bed_excluded_area(print_config);

|

||||

const Vec3d print_origin = print.get_plate_origin();

|

||||

for (int i = 0; i < excluse_area_points.size(); i++) {

|

||||

auto pt = excluse_area_points[i];

|

||||

exclude_poly.points.emplace_back(scale_(pt.x() + print_origin.x()), scale_(pt.y() + print_origin.y()));

|

||||

if (i % 4 == 3) { // exclude areas are always rectangle

|

||||

exclude_polys.push_back(exclude_poly);

|

||||

exclude_poly.points.clear();

|

||||

}

|

||||

}

|

||||

std::for_each(exclude_polys.begin(), exclude_polys.end(),

|

||||

[&print_origin](Polygon& p) { p.translate(scale_(print_origin.x()), scale_(print_origin.y())); });

|

||||

|

||||

std::map<ObjectID, Polygon> map_model_object_to_convex_hull;

|

||||

struct print_instance_info

|

||||

|

|

@ -887,19 +879,11 @@ static StringObjectException layered_print_cleareance_valid(const Print &print,

|

|||

if (print_instances_ordered.size() < 1)

|

||||

return {};

|

||||

|

||||

auto print_config = print.config();

|

||||

Pointfs excluse_area_points = print_config.bed_exclude_area.values;

|

||||

Polygons exclude_polys;

|

||||

Polygon exclude_poly;

|

||||

const auto& print_config = print.config();

|

||||

Polygons exclude_polys = get_bed_excluded_area(print_config);

|

||||

const Vec3d print_origin = print.get_plate_origin();

|

||||

for (int i = 0; i < excluse_area_points.size(); i++) {

|

||||

auto pt = excluse_area_points[i];

|

||||

exclude_poly.points.emplace_back(scale_(pt.x() + print_origin.x()), scale_(pt.y() + print_origin.y()));

|

||||

if (i % 4 == 3) { // exclude areas are always rectangle

|

||||

exclude_polys.push_back(exclude_poly);

|

||||

exclude_poly.points.clear();

|

||||

}

|

||||

}

|

||||

std::for_each(exclude_polys.begin(), exclude_polys.end(),

|

||||

[&print_origin](Polygon& p) { p.translate(scale_(print_origin.x()), scale_(print_origin.y())); });

|

||||

|

||||

std::map<const PrintInstance*, Polygon> map_model_object_to_convex_hull;

|

||||

// sequential_print_horizontal_clearance_valid

|

||||

|

|

|

|||

|

|

@ -8154,22 +8154,27 @@ Points get_bed_shape(const PrintConfig &cfg)

|

|||

|

||||

Points get_bed_shape(const SLAPrinterConfig &cfg) { return to_points(make_counter_clockwise(cfg.printable_area.values)); }

|

||||

|

||||

Polygons get_bed_excluded_area(const PrintConfig& cfg)

|

||||

{

|

||||

const Pointfs exclude_area_points = cfg.bed_exclude_area.values;

|

||||

|

||||

Polygon exclude_poly;

|

||||

for (int i = 0; i < exclude_area_points.size(); i++) {

|

||||

auto pt = exclude_area_points[i];

|

||||

exclude_poly.points.emplace_back(scale_(pt.x()), scale_(pt.y()));

|

||||

}

|

||||

|

||||

exclude_poly.make_counter_clockwise();

|

||||

|

||||

return {exclude_poly};

|

||||

}

|

||||

|

||||

Polygon get_bed_shape_with_excluded_area(const PrintConfig& cfg)

|

||||

{

|

||||

Polygon bed_poly;

|

||||

bed_poly.points = get_bed_shape(cfg);

|

||||

|

||||

Points excluse_area_points = to_points(cfg.bed_exclude_area.values);

|

||||

Polygons exclude_polys;

|

||||

Polygon exclude_poly;

|

||||

for (int i = 0; i < excluse_area_points.size(); i++) {

|

||||

auto pt = excluse_area_points[i];

|

||||

exclude_poly.points.emplace_back(pt);

|

||||

if (i % 4 == 3) { // exclude areas are always rectangle

|

||||

exclude_polys.push_back(exclude_poly);

|

||||

exclude_poly.points.clear();

|

||||

}

|

||||

}

|

||||

Polygons exclude_polys = get_bed_excluded_area(cfg);

|

||||

auto tmp = diff({ bed_poly }, exclude_polys);

|

||||

if (!tmp.empty()) bed_poly = tmp[0];

|

||||

return bed_poly;

|

||||

|

|

|

|||

|

|

@ -1751,6 +1751,7 @@ bool is_XL_printer(const PrintConfig &cfg);

|

|||

Points get_bed_shape(const DynamicPrintConfig &cfg);

|

||||

Points get_bed_shape(const PrintConfig &cfg);

|

||||

Points get_bed_shape(const SLAPrinterConfig &cfg);

|

||||

Slic3r::Polygons get_bed_excluded_area(const PrintConfig& cfg);

|

||||

Slic3r::Polygon get_bed_shape_with_excluded_area(const PrintConfig& cfg);

|

||||

bool has_skirt(const DynamicPrintConfig& cfg);

|

||||

float get_real_skirt_dist(const DynamicPrintConfig& cfg);

|

||||

|

|

|

|||

|

|

@ -235,7 +235,7 @@ AboutDialog::AboutDialog()

|

|||

bool is_dark = wxGetApp().app_config->get("dark_color_mode") == "1";

|

||||

|

||||

// logo

|

||||

m_logo_bitmap = ScalableBitmap(this, is_dark ? "OrcaSlicer_about_dark" : "OrcaSlicer_about", FromDIP(125));

|

||||

m_logo_bitmap = ScalableBitmap(this, is_dark ? "OrcaSlicer_about_dark" : "OrcaSlicer_about", 125);

|

||||

m_logo = new wxStaticBitmap(this, wxID_ANY, m_logo_bitmap.bmp(), wxDefaultPosition,wxDefaultSize, 0);

|

||||

m_logo->SetSizer(vesizer);

|

||||

|

||||

|

|

@ -258,7 +258,7 @@ AboutDialog::AboutDialog()

|

|||

#else

|

||||

version_font.SetPointSize(11);

|

||||

#endif

|

||||

version_font.SetPointSize(FromDIP(20));

|

||||

version_font.SetPointSize(20);

|

||||

version->SetFont(version_font);

|

||||

version->SetForegroundColour(wxColour("#949494"));

|

||||

credits_string->SetForegroundColour(wxColour("#949494"));

|

||||

|

|

|

|||

|

|

@ -855,9 +855,9 @@ void AuxiliaryPanel::init_tabpanel()

|

|||

sizer_side_tools->Add(back_btn, 1, wxEXPAND, 0);

|

||||

m_tabpanel = new Tabbook(this, wxID_ANY, wxDefaultPosition, wxDefaultSize, sizer_side_tools, wxNB_LEFT | wxTAB_TRAVERSAL | wxNB_NOPAGETHEME);

|

||||

m_tabpanel->SetBackgroundColour(wxColour("#FEFFFF"));

|

||||

m_tabpanel->Bind(wxEVT_BOOKCTRL_PAGE_CHANGED, [this](wxBookCtrlEvent &e) { ; });

|

||||

m_tabpanel->Bind(wxEVT_BOOKCTRL_PAGE_CHANGED, [](wxBookCtrlEvent &e) { /* Event handling */ });

|

||||

|

||||

m_designer_panel = new DesignerPanel(m_tabpanel, AuxiliaryFolderType::DESIGNER);

|

||||

m_designer_panel = new DesignerPanel(m_tabpanel, AuxiliaryFolderType::DESIGNER);

|

||||

m_pictures_panel = new AuFolderPanel(m_tabpanel, AuxiliaryFolderType::MODEL_PICTURE);

|

||||

m_bill_of_materials_panel = new AuFolderPanel(m_tabpanel, AuxiliaryFolderType::BILL_OF_MATERIALS);

|

||||

m_assembly_panel = new AuFolderPanel(m_tabpanel, AuxiliaryFolderType::ASSEMBLY_GUIDE);

|

||||

|

|

@ -1060,52 +1060,61 @@ void AuxiliaryPanel::update_all_cover()

|

|||

{

|

||||

SetBackgroundColour(AUFILE_GREY300);

|

||||

wxBoxSizer *m_sizer_body = new wxBoxSizer(wxVERTICAL);

|

||||

wxBoxSizer *m_sizer_designer = new wxBoxSizer(wxHORIZONTAL);

|

||||

|

||||

wxBoxSizer *m_sizer_designer = new wxBoxSizer(wxHORIZONTAL);

|

||||

auto m_text_designer = new wxStaticText(this, wxID_ANY, _L("Author"), wxDefaultPosition, wxSize(180, -1), 0);

|

||||

m_text_designer->Wrap(-1);

|

||||

m_text_designer->SetForegroundColour(*wxBLACK);

|

||||

m_sizer_designer->Add(m_text_designer, 0, wxALIGN_CENTER, 0);

|

||||

|

||||

m_input_designer = new ::TextInput(this, wxEmptyString, wxEmptyString, wxEmptyString, wxDefaultPosition, wxSize(FromDIP(450), FromDIP(30)), wxTE_PROCESS_ENTER);

|

||||

m_input_designer->GetTextCtrl()->SetFont(::Label::Body_14);

|

||||

m_input_designer->GetTextCtrl()->SetSize(wxSize(FromDIP(450), -1));

|

||||

m_sizer_designer->Add(m_input_designer, 0, wxALIGN_CENTER, 0);

|

||||

|

||||

wxBoxSizer *m_sizer_model_name = new wxBoxSizer(wxHORIZONTAL);

|

||||

|

||||

auto m_text_model_name = new wxStaticText(this, wxID_ANY, _L("Model Name"), wxDefaultPosition, wxSize(180, -1), 0);

|

||||

m_text_model_name->SetForegroundColour(*wxBLACK);

|

||||

m_text_model_name->Wrap(-1);

|

||||

m_sizer_model_name->Add(m_text_model_name, 0, wxALIGN_CENTER, 0);

|

||||

|

||||

m_imput_model_name = new ::TextInput(this, wxEmptyString, wxEmptyString, wxEmptyString, wxDefaultPosition,wxSize(FromDIP(450),FromDIP(30)), wxTE_PROCESS_ENTER);

|

||||

m_imput_model_name->GetTextCtrl()->SetFont(::Label::Body_14);

|

||||

m_imput_model_name->GetTextCtrl()->SetSize(wxSize(FromDIP(450), -1));

|

||||

m_sizer_model_name->Add(m_imput_model_name, 0, wxALIGN_CENTER, 0);

|

||||

m_input_model_name = new ::TextInput(this, wxEmptyString, wxEmptyString, wxEmptyString, wxDefaultPosition,wxSize(FromDIP(450),FromDIP(30)), wxTE_PROCESS_ENTER);

|

||||

m_input_model_name->GetTextCtrl()->SetFont(::Label::Body_14);

|

||||

m_input_model_name->GetTextCtrl()->SetSize(wxSize(FromDIP(450), -1));

|

||||

m_sizer_model_name->Add(m_input_model_name, 0, wxALIGN_CENTER, 0);

|

||||

|

||||

wxBoxSizer *m_sizer_license = new wxBoxSizer(wxHORIZONTAL);

|

||||

auto m_text_license = new wxStaticText(this, wxID_ANY, _L("License"), wxDefaultPosition, wxSize(180, -1), 0);

|

||||

m_text_license->Wrap(-1);

|

||||

m_sizer_license->Add(m_text_license, 0, wxALIGN_CENTER, 0);

|

||||

|

||||

m_combo_license = new ComboBox(this, wxID_ANY, wxEmptyString, wxDefaultPosition, wxSize(FromDIP(450), -1), 0, NULL, wxCB_READONLY);

|

||||

m_sizer_license->Add(m_combo_license, 0, wxALIGN_CENTER, 0);

|

||||

|

||||

m_sizer_body->Add( 0, 0, 0, wxTOP, FromDIP(50) );

|

||||

m_sizer_body->Add(m_sizer_designer, 0, wxLEFT, FromDIP(50));

|

||||

m_sizer_body->Add( 0, 0, 0, wxTOP, FromDIP(20));

|

||||

m_sizer_body->Add(m_sizer_model_name, 0, wxLEFT, FromDIP(50));

|

||||

wxBoxSizer *m_sizer_description = new wxBoxSizer(wxHORIZONTAL);

|

||||

auto m_text_description = new wxStaticText(this, wxID_ANY, _L("Description:"), wxDefaultPosition, wxSize(170, -1), 0); // Using "Description:" with the : because that already exists in the Localizations files

|

||||

m_text_description->SetForegroundColour(*wxBLACK);

|

||||

m_text_description->Wrap(-1);

|

||||

m_sizer_description->Add(m_text_description, 0, wxALIGN_TOP | wxRIGHT, FromDIP(10));

|

||||

m_input_description = new wxTextCtrl(this, wxID_ANY, wxEmptyString, wxDefaultPosition,

|

||||

wxSize(FromDIP(450), FromDIP(300)), wxTE_MULTILINE | wxTE_PROCESS_ENTER);

|

||||

m_input_description->SetFont(::Label::Body_14);

|

||||

m_sizer_description->Add(m_input_description, 0, wxALIGN_CENTER, 0);

|

||||

|

||||

m_sizer_body->Add(0, 0, 0, wxTOP, FromDIP(50));

|

||||

m_sizer_body->Add(m_sizer_designer, 0, wxLEFT | wxALIGN_LEFT, FromDIP(50));

|

||||

m_sizer_body->Add(0, 0, 0, wxTOP, FromDIP(20));

|

||||

m_sizer_body->Add(m_sizer_license, 0, wxLEFT, FromDIP(50));

|

||||

m_sizer_body->Add(m_sizer_model_name, 0, wxLEFT | wxALIGN_LEFT, FromDIP(50));

|

||||

m_sizer_body->Add(0, 0, 0, wxTOP, FromDIP(20));

|

||||

m_sizer_body->Add(m_sizer_license, 0, wxLEFT | wxALIGN_LEFT, FromDIP(50));

|

||||

init_license_list();

|

||||

m_sizer_body->Add(0, 0, 0, wxTOP, FromDIP(20));

|

||||

m_sizer_body->Add(m_sizer_description, 0, wxLEFT | wxALIGN_LEFT, FromDIP(50));

|

||||

|

||||

SetSizer(m_sizer_body);

|

||||

Layout();

|

||||

Fit();

|

||||

|

||||

m_input_designer->Bind(wxEVT_TEXT, &DesignerPanel::on_input_enter_designer, this);

|

||||

m_imput_model_name->Bind(wxEVT_TEXT, &DesignerPanel::on_input_enter_model, this);

|

||||

m_input_model_name->Bind(wxEVT_TEXT, &DesignerPanel::on_input_enter_model, this);

|

||||

m_input_description->Bind(wxEVT_TEXT, &DesignerPanel::on_input_enter_description, this);

|

||||

m_combo_license->Bind(wxEVT_COMMAND_COMBOBOX_SELECTED, &DesignerPanel::on_select_license, this);

|

||||

}

|

||||

|

||||

|

|

@ -1148,6 +1157,12 @@ void DesignerPanel::on_input_enter_model(wxCommandEvent &evt)

|

|||

ensure_model_info()->model_name = std::string(text.ToUTF8().data());

|

||||

}

|

||||

|

||||

void DesignerPanel::on_input_enter_description(wxCommandEvent &evt)

|

||||

{

|

||||

auto text = evt.GetString();

|

||||

ensure_model_info()->description = std::string(text.ToUTF8().data());

|

||||

}

|

||||

|

||||

void DesignerPanel::update_info()

|

||||

{

|

||||

if (wxGetApp().plater()->model().design_info != nullptr) {

|

||||

|

|

@ -1158,12 +1173,14 @@ void DesignerPanel::update_info()

|

|||

}

|

||||

|

||||

if (wxGetApp().plater()->model().model_info != nullptr) {

|

||||

m_imput_model_name->GetTextCtrl()->SetValue(wxString::FromUTF8(wxGetApp().plater()->model().model_info->model_name));

|

||||

m_input_model_name->GetTextCtrl()->SetValue(wxString::FromUTF8(wxGetApp().plater()->model().model_info->model_name));

|

||||

m_input_description->ChangeValue(wxString::FromUTF8(wxGetApp().plater()->model().model_info->description));

|

||||

if (!m_combo_license->SetStringSelection(wxString::FromUTF8(wxGetApp().plater()->model().model_info->license))) {

|

||||

m_combo_license->SetSelection(0);

|

||||

}

|

||||

} else {

|

||||

m_imput_model_name->GetTextCtrl()->SetValue(wxEmptyString);

|

||||

m_input_model_name->GetTextCtrl()->SetValue(wxEmptyString);

|

||||

m_input_description->ChangeValue(wxEmptyString);

|

||||

m_combo_license->SetSelection(0);

|

||||

}

|

||||

}

|

||||

|

|

@ -1171,8 +1188,8 @@ void DesignerPanel::update_info()

|

|||

void DesignerPanel::msw_rescale()

|

||||

{

|

||||

m_input_designer->GetTextCtrl()->SetSize(wxSize(FromDIP(450), -1));

|

||||

m_imput_model_name->GetTextCtrl()->SetSize(wxSize(FromDIP(450), -1));

|

||||

m_input_model_name->GetTextCtrl()->SetSize(wxSize(FromDIP(450), -1));

|

||||

m_combo_license->SetSize(wxSize(FromDIP(450), -1));

|

||||

}

|

||||

m_input_description->SetSize(wxSize(FromDIP(450), -1));}

|

||||

|

||||

}} // namespace Slic3r::GUI

|

||||

|

|

|

|||

|

|

@ -180,12 +180,14 @@ public:

|

|||

~DesignerPanel();

|

||||

|

||||

::TextInput* m_input_designer {nullptr};

|

||||

::TextInput* m_imput_model_name {nullptr};

|

||||

::TextInput* m_input_model_name {nullptr};

|

||||

wxTextCtrl* m_input_description {nullptr};

|

||||

ComboBox* m_combo_license {nullptr};

|

||||

bool Show(bool show) override;

|

||||

void init_license_list();

|

||||

void on_input_enter_designer(wxCommandEvent &evt);

|

||||

void on_input_enter_model(wxCommandEvent &evt);

|

||||

void on_input_enter_description(wxCommandEvent &evt);

|

||||

void on_select_license(wxCommandEvent& evt);

|

||||

void update_info();

|

||||

void msw_rescale();

|

||||

|

|

|

|||

|

|

@ -521,8 +521,11 @@ void ConfigManipulation::toggle_print_fff_options(DynamicPrintConfig *config, co

|

|||

bool have_combined_infill = config->opt_bool("infill_combination") && have_infill;

|

||||

toggle_line("infill_combination_max_layer_height", have_combined_infill);

|

||||

|

||||

bool infill_anchor = config->opt_enum<InfillPattern>("sparse_infill_pattern") != ipLine;

|

||||

toggle_field("infill_anchor_max",infill_anchor);

|

||||

|

||||

// Only allow configuration of open anchors if the anchoring is enabled.

|

||||

bool has_infill_anchors = have_infill && config->option<ConfigOptionFloatOrPercent>("infill_anchor_max")->value > 0;

|

||||

bool has_infill_anchors = have_infill && config->option<ConfigOptionFloatOrPercent>("infill_anchor_max")->value > 0 && infill_anchor;

|

||||

toggle_field("infill_anchor", has_infill_anchors);

|

||||

|

||||

bool has_spiral_vase = config->opt_bool("spiral_mode");

|

||||

|

|

|

|||

|

|

@ -7911,11 +7911,11 @@ void GLCanvas3D::_render_imgui_select_plate_toolbar()

|

|||

m_render_preview = true;

|

||||

|

||||

// places the toolbar on the top_left corner of the 3d scene

|

||||

#if ENABLE_RETINA_GL

|

||||

float f_scale = m_retina_helper->get_scale_factor();

|

||||

#else

|

||||

float f_scale = wxGetApp().em_unit() / 10; // ORCA add scaling support

|

||||

#endif

|

||||

float f_scale = get_scale();

|

||||

#ifdef WIN32

|

||||

const int dpi = get_dpi_for_window(wxGetApp().GetTopWindow());

|

||||

f_scale *= (float) dpi / (float) DPI_DEFAULT;

|

||||

#endif // WIN32

|

||||

Size cnv_size = get_canvas_size();

|

||||

auto canvas_w = float(cnv_size.get_width());

|

||||

auto canvas_h = float(cnv_size.get_height());

|

||||

|

|

@ -7935,16 +7935,15 @@ void GLCanvas3D::_render_imgui_select_plate_toolbar()

|

|||

// Make sure the window does not overlap the 3d navigator

|

||||

auto window_height_max = canvas_h - y_offset;

|

||||

if (wxGetApp().show_3d_navigator()) {

|

||||

float sc = get_scale();

|

||||

#ifdef WIN32

|

||||

const int dpi = get_dpi_for_window(wxGetApp().GetTopWindow());

|

||||

sc *= (float) dpi / (float) DPI_DEFAULT;

|

||||

#endif // WIN32

|

||||

window_height_max -= (128 * sc + 5);

|

||||

window_height_max -= (128 * f_scale + 5);

|

||||

}

|

||||

|

||||

// ORCA simplify and correct window size and margin calculations and get values from style

|

||||

ImGuiWrapper& imgui = *wxGetApp().imgui();

|

||||

|

||||

ImGui::PushStyleVar(ImGuiStyleVar_WindowPadding, ImVec2(8.0f, 8.0f) * f_scale);

|

||||

ImGui::PushStyleVar(ImGuiStyleVar_ItemSpacing, ImVec2(4.0f, 4.0f) * f_scale);

|

||||

|

||||

int item_count = m_sel_plate_toolbar.m_items.size() + (m_sel_plate_toolbar.show_stats_item ? 1 : 0);

|

||||

float window_height_calc = (item_count * (button_height + (margin_size + button_margin) * 2.0f) + (item_count - 1) * ImGui::GetStyle().ItemSpacing.y + ImGui::GetStyle().WindowPadding.y * 2.0f);

|

||||

bool show_scroll = m_sel_plate_toolbar.is_display_scrollbar && (window_height_calc > window_height_max);

|

||||

|

|

@ -8180,7 +8179,7 @@ void GLCanvas3D::_render_imgui_select_plate_toolbar()

|

|||

}

|

||||

ImGui::SetWindowFontScale(1.0f);

|

||||

ImGui::PopStyleColor(8);

|

||||

ImGui::PopStyleVar(5);

|

||||

ImGui::PopStyleVar(7);

|

||||

|

||||

if (ImGui::IsWindowHovered() || is_hovered) {

|

||||

m_sel_plate_toolbar.is_display_scrollbar = true;

|

||||

|

|

|

|||

|

|

@ -458,17 +458,7 @@ void ArrangeJob::prepare()

|

|||

auto& print = wxGetApp().plater()->get_partplate_list().get_current_fff_print();

|

||||

auto print_config = print.config();

|

||||

bed_poly.points = get_bed_shape(*m_plater->config());

|

||||

Pointfs excluse_area_points = print_config.bed_exclude_area.values;

|

||||

Polygons exclude_polys;

|

||||

Polygon exclude_poly;

|

||||

for (int i = 0; i < excluse_area_points.size(); i++) {

|

||||

auto pt = excluse_area_points[i];

|

||||

exclude_poly.points.emplace_back(scale_(pt.x()), scale_(pt.y()));

|

||||

if (i % 4 == 3) { // exclude areas are always rectangle

|

||||

exclude_polys.push_back(exclude_poly);

|

||||

exclude_poly.points.clear();

|

||||

}

|

||||

}

|

||||

Polygons exclude_polys = get_bed_excluded_area(print_config);

|

||||

bed_poly = diff({ bed_poly }, exclude_polys)[0];

|

||||

}

|

||||

|

||||

|

|

|

|||

|

|

@ -1562,9 +1562,9 @@ wxBoxSizer* MainFrame::create_side_tools()

|

|||

|

||||

// m_publish_btn = new Button(this, _L("Upload"), "bar_publish", 0, FromDIP(16));

|

||||

m_slice_btn = new SideButton(this, _L("Slice plate"), "");

|

||||

m_slice_option_btn = new SideButton(this, "", "sidebutton_dropdown", 0, FromDIP(14));

|

||||

m_slice_option_btn = new SideButton(this, "", "sidebutton_dropdown", 0, 14);

|

||||

m_print_btn = new SideButton(this, _L("Print plate"), "");

|

||||

m_print_option_btn = new SideButton(this, "", "sidebutton_dropdown", 0, FromDIP(14));

|

||||

m_print_option_btn = new SideButton(this, "", "sidebutton_dropdown", 0, 14);

|

||||

|

||||

update_side_button_style();

|

||||

// m_publish_btn->Hide();

|

||||

|

|

@ -1572,12 +1572,10 @@ wxBoxSizer* MainFrame::create_side_tools()

|

|||

m_print_option_btn->Enable();

|

||||

// sizer->Add(m_publish_btn, 0, wxLEFT | wxALIGN_CENTER_VERTICAL, FromDIP(1));

|

||||

// sizer->Add(FromDIP(15), 0, 0, 0, 0);

|

||||

sizer->Add(m_slice_option_btn, 0, wxRIGHT | wxALIGN_CENTER_VERTICAL, FromDIP(1));

|

||||

sizer->Add(m_slice_btn, 0, wxLEFT | wxALIGN_CENTER_VERTICAL, FromDIP(1));

|

||||

sizer->Add(FromDIP(15), 0, 0, 0, 0);

|

||||

sizer->Add(m_print_option_btn, 0, wxRIGHT | wxALIGN_CENTER_VERTICAL, FromDIP(1));

|

||||

sizer->Add(m_print_btn, 0, wxLEFT | wxALIGN_CENTER_VERTICAL, FromDIP(1));

|

||||

sizer->Add(FromDIP(19), 0, 0, 0, 0);

|

||||

sizer->Add(m_slice_option_btn, 0, wxRIGHT | wxALIGN_CENTER_VERTICAL, FromDIP(2));

|

||||

sizer->Add(m_slice_btn , 0, wxRIGHT | wxALIGN_CENTER_VERTICAL, FromDIP(15));

|

||||

sizer->Add(m_print_option_btn, 0, wxRIGHT | wxALIGN_CENTER_VERTICAL, FromDIP(2));

|

||||

sizer->Add(m_print_btn , 0, wxRIGHT | wxALIGN_CENTER_VERTICAL, FromDIP(19));

|

||||

|

||||

sizer->Layout();

|

||||

|

||||

|

|

|

|||

|

|

@ -10185,7 +10185,6 @@ void Plater::calib_VFA(const Calib_Params& params)

|

|||

auto print_config = &wxGetApp().preset_bundle->prints.get_edited_preset().config;

|

||||

auto filament_config = &wxGetApp().preset_bundle->filaments.get_edited_preset().config;

|

||||

filament_config->set_key_value("slow_down_layer_time", new ConfigOptionFloats { 0.0 });

|

||||

filament_config->set_key_value("filament_max_volumetric_speed", new ConfigOptionFloats { 200 });

|

||||

print_config->set_key_value("enable_overhang_speed", new ConfigOptionBool { false });

|

||||

print_config->set_key_value("timelapse_type", new ConfigOptionEnum<TimelapseType>(tlTraditional));

|

||||

print_config->set_key_value("wall_loops", new ConfigOptionInt(1));

|

||||

|

|

@ -10232,7 +10231,6 @@ void Plater::calib_input_shaping_freq(const Calib_Params& params)

|

|||

filament_config->set_key_value("slow_down_layer_time", new ConfigOptionFloats { 0.0 });

|

||||

filament_config->set_key_value("slow_down_min_speed", new ConfigOptionFloats { 0.0 });

|

||||

filament_config->set_key_value("slow_down_for_layer_cooling", new ConfigOptionBools{false});

|

||||

filament_config->set_key_value("filament_max_volumetric_speed", new ConfigOptionFloats { 200 });

|

||||

filament_config->set_key_value("enable_pressure_advance", new ConfigOptionBools {false });

|

||||

filament_config->set_key_value("pressure_advance", new ConfigOptionFloats { 0.0 });

|

||||

print_config->set_key_value("layer_height", new ConfigOptionFloat(0.2));

|

||||

|

|

@ -10259,7 +10257,7 @@ void Plater::calib_input_shaping_freq(const Calib_Params& params)

|

|||

wxGetApp().get_tab(Preset::TYPE_FILAMENT)->update_dirty();

|

||||

wxGetApp().get_tab(Preset::TYPE_PRINT)->update_ui_from_settings();

|

||||

wxGetApp().get_tab(Preset::TYPE_FILAMENT)->update_ui_from_settings();

|

||||

|

||||

|

||||

p->background_process.fff_print()->set_calib_params(params);

|

||||

}

|

||||

|

||||

|

|

@ -10279,7 +10277,6 @@ void Plater::calib_input_shaping_damp(const Calib_Params& params)

|

|||

filament_config->set_key_value("slow_down_layer_time", new ConfigOptionFloats { 0.0 });

|

||||

filament_config->set_key_value("slow_down_min_speed", new ConfigOptionFloats { 0.0 });

|

||||

filament_config->set_key_value("slow_down_for_layer_cooling", new ConfigOptionBools{false});

|

||||

filament_config->set_key_value("filament_max_volumetric_speed", new ConfigOptionFloats { 200 });

|

||||

filament_config->set_key_value("enable_pressure_advance", new ConfigOptionBools{false});

|

||||

filament_config->set_key_value("pressure_advance", new ConfigOptionFloats{0.0});

|

||||

print_config->set_key_value("layer_height", new ConfigOptionFloat(0.2));

|

||||

|

|

@ -10306,7 +10303,7 @@ void Plater::calib_input_shaping_damp(const Calib_Params& params)

|

|||

wxGetApp().get_tab(Preset::TYPE_FILAMENT)->update_dirty();

|

||||

wxGetApp().get_tab(Preset::TYPE_PRINT)->update_ui_from_settings();

|

||||

wxGetApp().get_tab(Preset::TYPE_FILAMENT)->update_ui_from_settings();

|

||||

|

||||

|

||||

p->background_process.fff_print()->set_calib_params(params);

|

||||

}

|

||||

|

||||

|

|

|

|||

|

|

@ -76,6 +76,16 @@ ProjectPanel::ProjectPanel(wxWindow *parent, wxWindowID id, const wxPoint &pos,

|

|||

|

||||

ProjectPanel::~ProjectPanel() {}

|

||||

|

||||

// Helper to convert newlines to <br>

|

||||

static std::string convert_newlines_to_br(const std::string& text) {

|

||||

std::string result = text;

|

||||

size_t pos = 0;

|

||||

while ((pos = result.find('\n', pos)) != std::string::npos) {

|

||||

result.replace(pos, 1, "<br>");

|

||||

pos += 4;

|

||||

}

|

||||

return result;

|

||||

}

|

||||

|

||||

void ProjectPanel::onWebNavigating(wxWebViewEvent& evt)

|

||||

{

|

||||

|

|

@ -189,7 +199,7 @@ void ProjectPanel::on_reload(wxCommandEvent& evt)

|

|||

j["model"]["name"] = wxGetApp().url_encode(model_name);

|

||||

j["model"]["author"] = wxGetApp().url_encode(model_author);;

|

||||

j["model"]["cover_img"] = wxGetApp().url_encode(cover_file);

|

||||

j["model"]["description"] = wxGetApp().url_encode(description);

|

||||

j["model"]["description"] = wxGetApp().url_encode(convert_newlines_to_br(description));

|

||||

j["model"]["preview_img"] = files["Model Pictures"];

|

||||

j["model"]["upload_type"] = update_type;

|

||||

|

||||

|

|

|

|||

Loading…

Add table

Add a link

Reference in a new issue