Wiki fix images and links (#9858)

* Fix Wiki Links Co-Authored-By: StdVectorBool <4926951+StdVectorBool@users.noreply.github.com> * Fix Wiki images * Chamber temp Wiki update --------- Co-authored-by: StdVectorBool <4926951+StdVectorBool@users.noreply.github.com>

|

|

@ -106,9 +106,9 @@ winget install --id=SoftFever.OrcaSlicer --e

|

||||||

```

|

```

|

||||||

- Option 3:

|

- Option 3:

|

||||||

- Step 1: open the app, a warning window will pop up

|

- Step 1: open the app, a warning window will pop up

|

||||||

|

|

||||||

- Step 2: in `System Settings` -> `Privacy & Security`, click `Open Anyway`:

|

- Step 2: in `System Settings` -> `Privacy & Security`, click `Open Anyway`:

|

||||||

|

|

||||||

</details>

|

</details>

|

||||||

|

|

||||||

## Linux (Ubuntu):

|

## Linux (Ubuntu):

|

||||||

|

|

|

||||||

|

|

@ -2,9 +2,9 @@

|

||||||

|

|

||||||

OrcaSlicer use `M141/M191` command to control active chamber heater.

|

OrcaSlicer use `M141/M191` command to control active chamber heater.

|

||||||

|

|

||||||

If `Activate temperature control` is checked, OrcaSlicer will insert `M191` command at the beginning of the gcode(before `Machine G-code`).

|

If your Filament's `Activate temperature control` and your printer `Support control chamber temperature` option are checked , OrcaSlicer will insert `M191` command at the beginning of the gcode (before `Machine G-code`).

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

> [!NOTE]

|

> [!NOTE]

|

||||||

> If the machine is equipped with an auxiliary fan, OrcaSlicer will automatically activate the fan during the heating period to help circulate air in the chamber.

|

> If the machine is equipped with an auxiliary fan, OrcaSlicer will automatically activate the fan during the heating period to help circulate air in the chamber.

|

||||||

|

|

|

||||||

26

doc/Home.md

|

|

@ -35,22 +35,22 @@ The below sections provide a detailed settings explanation as well as tips and t

|

||||||

|

|

||||||

## Printer Calibration

|

## Printer Calibration

|

||||||

|

|

||||||

The [Calibration Guide](./print_settings/calibration/Calibration.md) takes you through the key calibration tests in Orca - flow rate, pressure advance, print temperature, retraction, tolerances, etc.

|

The [Calibration Guide](Calibration) takes you through the key calibration tests in Orca - flow rate, pressure advance, print temperature, retraction, tolerances, etc.

|

||||||

|

|

||||||

- [Flow Rate](print_settings/calibration/flow-rate-calib.md)

|

- [Flow Rate](flow-rate-calib)

|

||||||

- [Pressure Advance](print_settings/calibration/pressure-advance-calib.md)

|

- [Pressure Advance](pressure-advance-calib)

|

||||||

- [Temperature](print_settings/calibration/temp-calib.md)

|

- [Temperature](temp-calib)

|

||||||

- [Retraction](print_settings/calibration/retraction-calib.md)

|

- [Retraction](retraction-calib)

|

||||||

- [Tolerance](print_settings/calibration/tolerance-calib.md)

|

- [Tolerance](tolerance-calib)

|

||||||

- Advanced:

|

- Advanced:

|

||||||

- [Volumetric Speed](print_settings/calibration/volumetric-speed-calib.md)

|

- [Volumetric Speed](volumetric-speed-calib)

|

||||||

- [Adaptive Pressure Advance Guide](print_settings/calibration/adaptive-pressure-advance-calib.md)

|

- [Adaptive Pressure Advance Guide](adaptive-pressure-advance-calib)

|

||||||

- [Input Shaping](print_settings/calibration/input-shaping-calib.md)

|

- [Input Shaping](input-shaping-calib)

|

||||||

- [Cornering (Jerk & Junction Deviation)](print_settings/calibration/cornering-calib.md)

|

- [Cornering (Jerk & Junction Deviation)](cornering-calib)

|

||||||

|

|

||||||

## Developer Section

|

## Developer Section

|

||||||

|

|

||||||

- [How to build Orca Slicer](./How-to-build)

|

- [How to build Orca Slicer](How-to-build)

|

||||||

- [Localization and translation guide](Localization_guide)

|

- [Localization and translation guide](Localization_guide)

|

||||||

- [Developer Reference](https://github.com/SoftFever/OrcaSlicer/blob/main/doc/developer-reference/Home.md)

|

- [Developer Reference](Developers-Home)

|

||||||

- [How to create profiles](./How-to-create-profiles)

|

- [How to create profiles](How-to-create-profiles)

|

||||||

|

|

|

||||||

|

|

@ -6,11 +6,17 @@ The 'Precise Wall' is a distinctive feature introduced by OrcaSlicer, aimed at i

|

||||||

|

|

||||||

Below is a technical explanation of how this feature works.

|

Below is a technical explanation of how this feature works.

|

||||||

|

|

||||||

First, it's important to understand some basic concepts like flow, extrusion width, and space. Slic3r has an excellent document that covers these topics in detail. You can refer to this article: [link to article](https://manual.slic3r.org/advanced/flow-math).

|

First, it's important to understand some basic concepts like flow, extrusion width, and space. Slic3r has an excellent document that covers these topics in detail. You can refer to this [article](https://manual.slic3r.org/advanced/flow-math).

|

||||||

|

|

||||||

Now, let's dive into the specifics. Slic3r and its forks, such as PrusaSlicer, SuperSlicer, and OrcaSlicer, assume that the extrusion path has an oval shape, which accounts for the overlaps. For example, if we set the wall width to 0.4mm and the layer height to 0.2mm, the combined thickness of two walls laid side by side is 0.714mm instead of 0.8mm due to the overlapping.

|

Now, let's dive into the specifics. Slic3r and its forks, such as PrusaSlicer, SuperSlicer, and OrcaSlicer, assume that the extrusion path has an oval shape, which accounts for the overlaps. For example, if we set the wall width to 0.4mm and the layer height to 0.2mm, the combined thickness of two walls laid side by side is 0.714mm instead of 0.8mm due to the overlapping.

|

||||||

|

|

||||||

|

- **Precise Wall Off**

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

|

- **Precise Wall On**

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

This approach enhances the strength of 3D-printed parts. However, it does have some side effects. For instance, when the inner-outer wall order is used, the outer wall can be pushed outside, leading to potential size inaccuracy and more layer inconsistency.

|

This approach enhances the strength of 3D-printed parts. However, it does have some side effects. For instance, when the inner-outer wall order is used, the outer wall can be pushed outside, leading to potential size inaccuracy and more layer inconsistency.

|

||||||

|

|

||||||

|

|

|

||||||

|

|

@ -6,7 +6,7 @@ WIP...

|

||||||

|

|

||||||

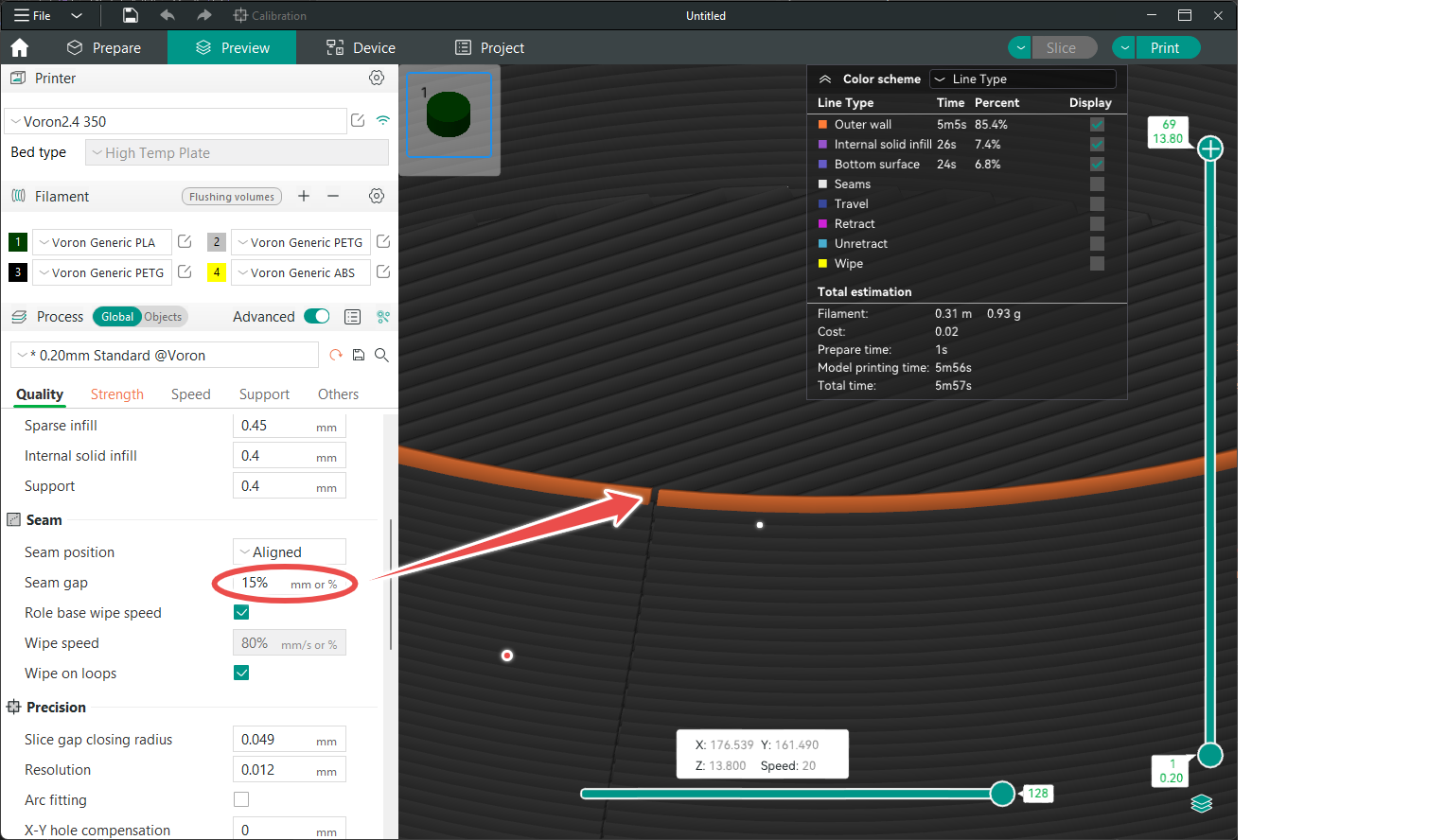

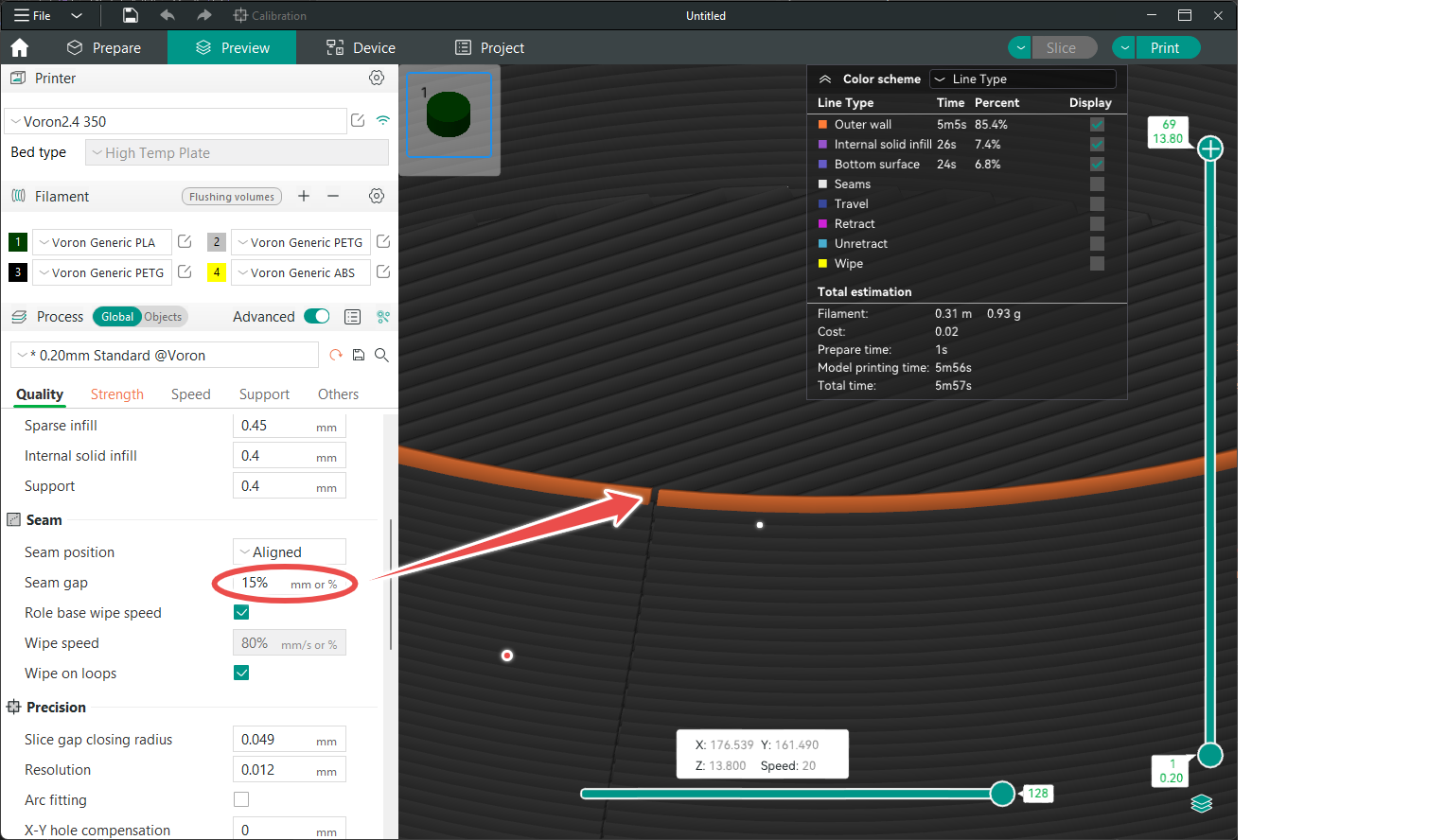

### Seam gap

|

### Seam gap

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

### Role-based wipe speed(auto)

|

### Role-based wipe speed(auto)

|

||||||

|

|

||||||

|

|

@ -18,14 +18,14 @@ WIP...

|

||||||

|

|

||||||

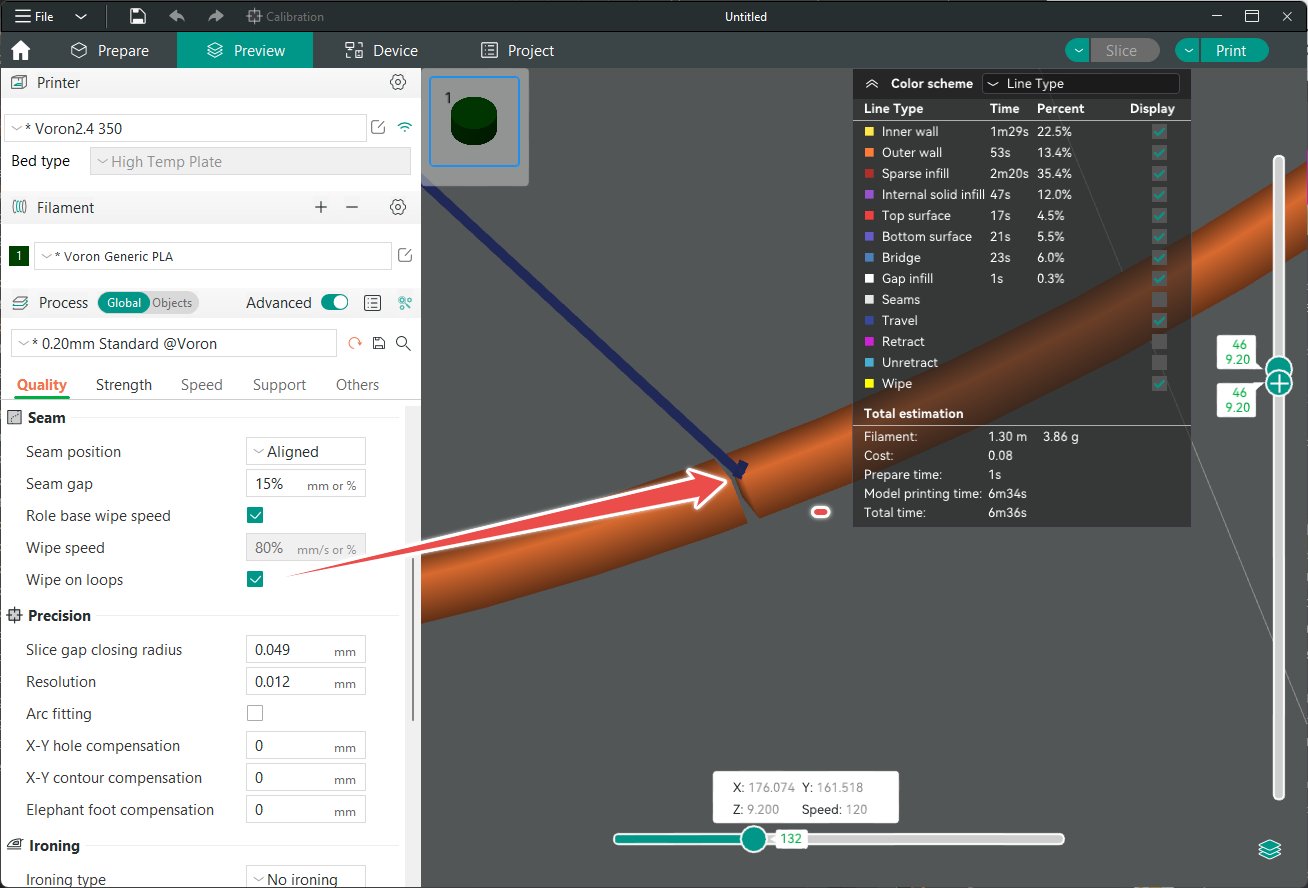

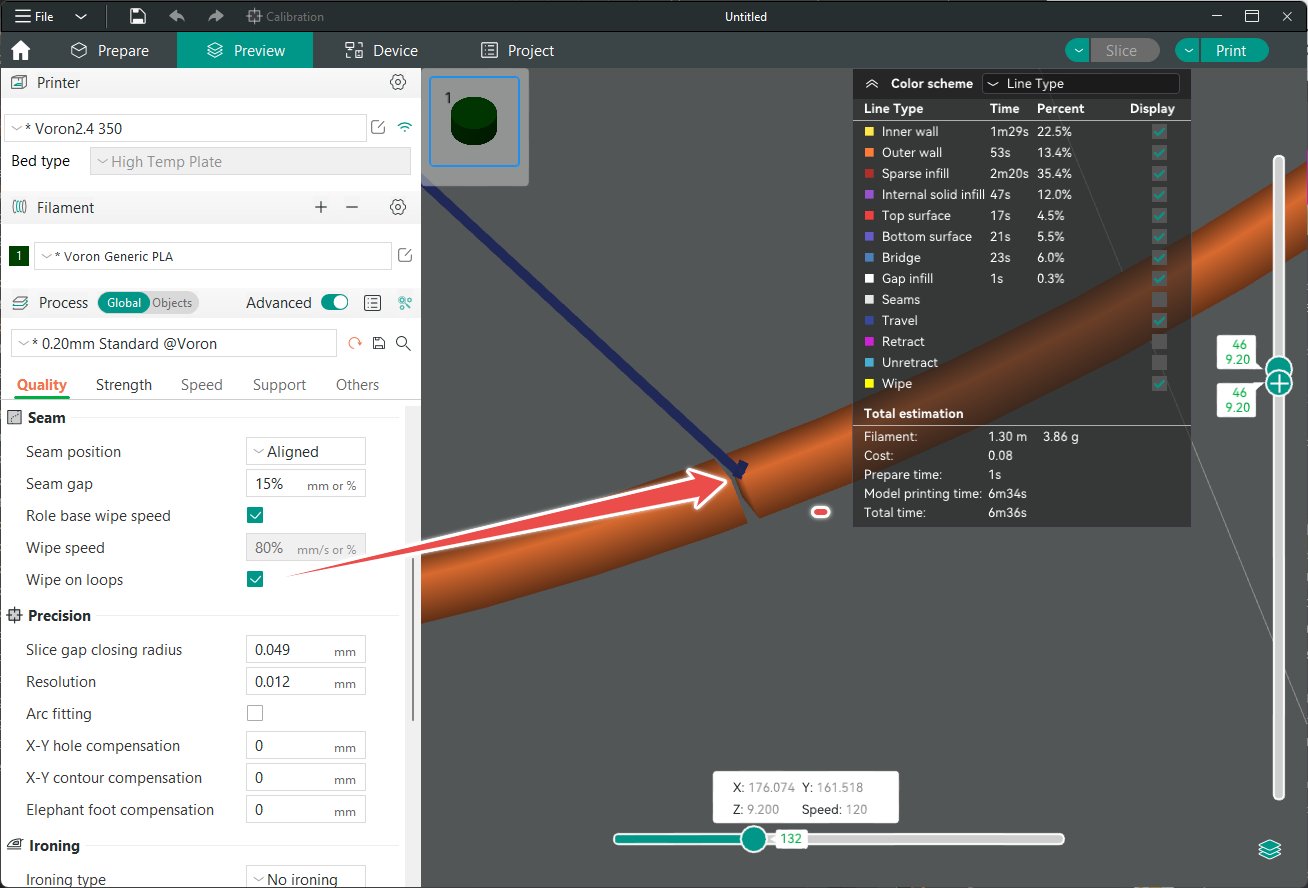

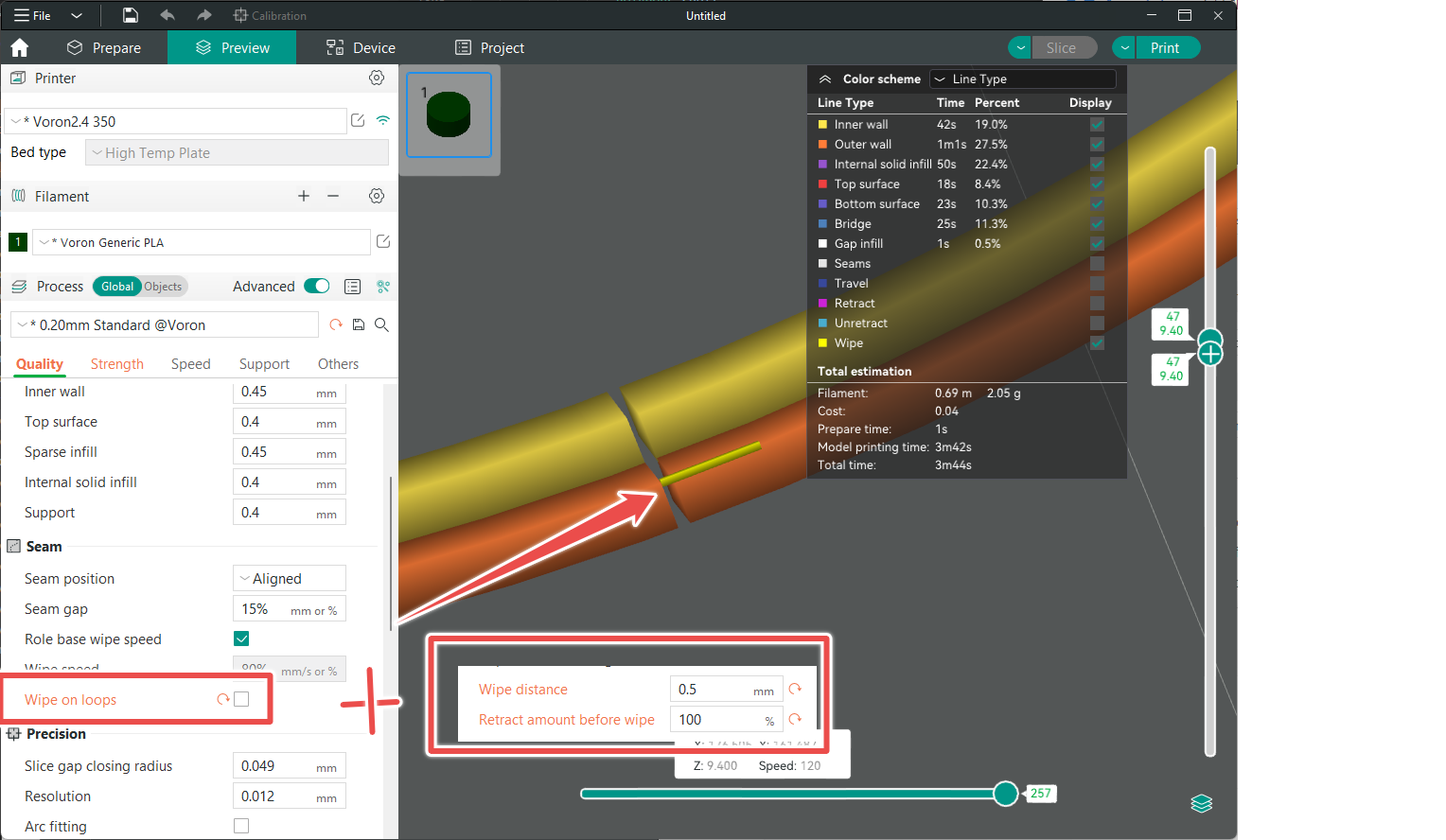

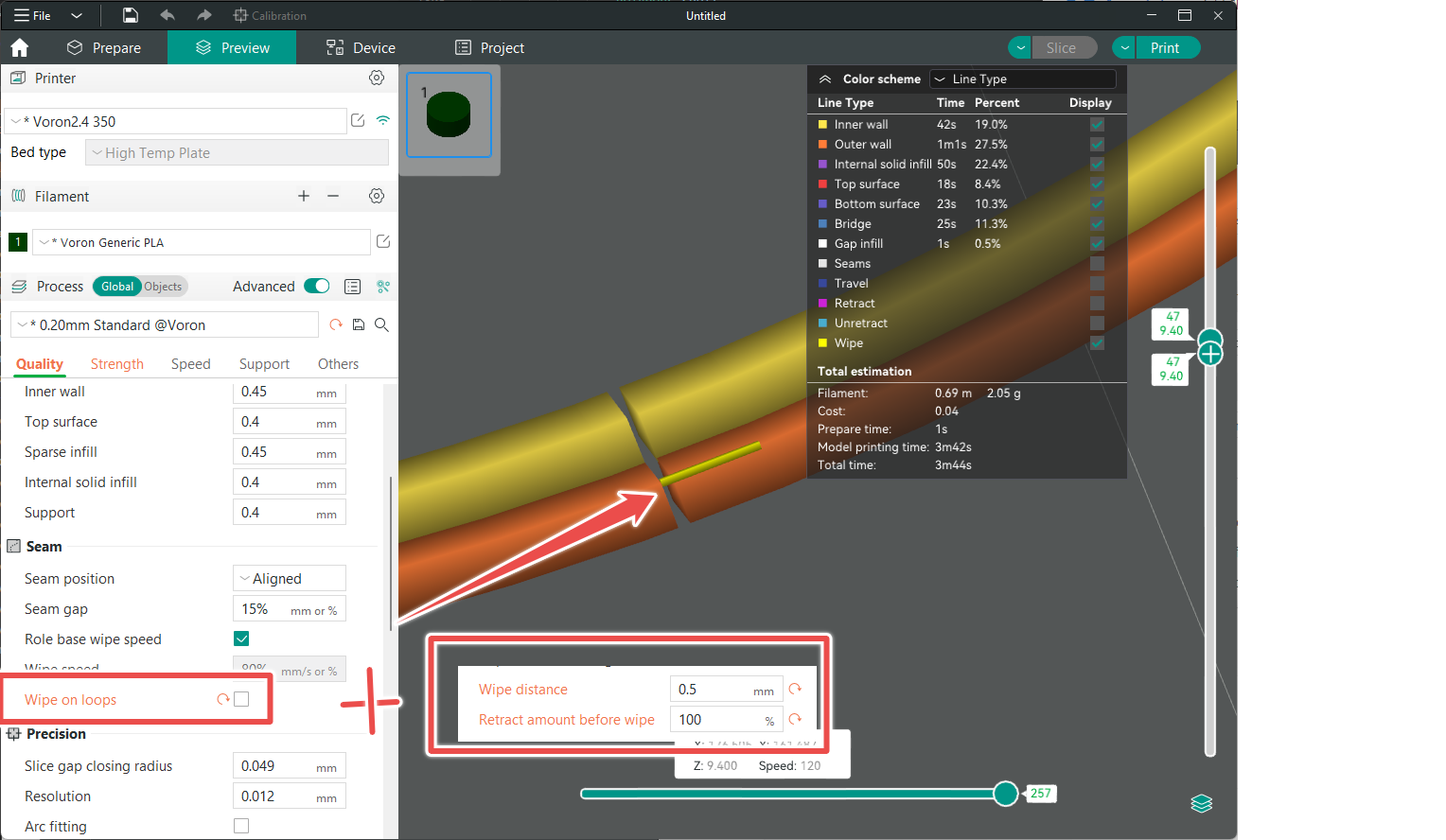

### Wipe on loop(inward movement)

|

### Wipe on loop(inward movement)

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

Use outer wall speed and acceleration instead of travel speed and acceleration.

|

Use outer wall speed and acceleration instead of travel speed and acceleration.

|

||||||

Added an option to disable this feature

|

Added an option to disable this feature

|

||||||

|

|

||||||

### Support Cura style outer wall wipe(100% retract before wipe)

|

### Support Cura style outer wall wipe(100% retract before wipe)

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

Extra length on restart

|

Extra length on restart

|

||||||

|

|

@ -138,7 +138,7 @@ It is recommended that the PA step is set to a small value, to allow you to make

|

||||||

|

|

||||||

PA pattern calibration configuration window have been changed to simplify test setup. Now all is needed is to fill list of accelerations and speeds into relevant fields of the calibration window:

|

PA pattern calibration configuration window have been changed to simplify test setup. Now all is needed is to fill list of accelerations and speeds into relevant fields of the calibration window:

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

Test patterns generated for each acceleration-speed pair and all parameters are set accordingly. No additional actions needed from user side. Just slice and print all plates generated.

|

Test patterns generated for each acceleration-speed pair and all parameters are set accordingly. No additional actions needed from user side. Just slice and print all plates generated.

|

||||||

|

|

||||||

|

|

|

||||||

|

|

@ -5,7 +5,7 @@ You can enable it in printer settings.

|

||||||

Once enabled, you can select the bed type in the drop-down menu, corresponding bed temperature will be set automatically.

|

Once enabled, you can select the bed type in the drop-down menu, corresponding bed temperature will be set automatically.

|

||||||

You can set the bed temperature for each bed type in the filament settings as demonstrated in the following image.

|

You can set the bed temperature for each bed type in the filament settings as demonstrated in the following image.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

Orca also support `curr_bed_type` variable in custom G-code.

|

Orca also support `curr_bed_type` variable in custom G-code.

|

||||||

For example, the following sample G-codes can detect the selected bed type and adjust the G-code offset accordingly for Klipper:

|

For example, the following sample G-codes can detect the selected bed type and adjust the G-code offset accordingly for Klipper:

|

||||||

|

|

|

||||||

7

doc/developer-reference/Developers-Home.md

Normal file

|

|

@ -0,0 +1,7 @@

|

||||||

|

# For Developers

|

||||||

|

|

||||||

|

This is a documentation from someone exploring the code and is by no means complete or even completely accurate. Please edit the parts you might find inaccurate. This is probably going to be helpful nonetheless.

|

||||||

|

|

||||||

|

- [Preset, PresetBundle and PresetCollection](Preset-and-bundle)

|

||||||

|

- [Plater, Sidebar, Tab, ComboBox](plater-sidebar-tab-combobox)

|

||||||

|

- [Slicing Call Hierarchy](slicing-hierarchy)

|

||||||

|

|

@ -1,7 +0,0 @@

|

||||||

# For Developers

|

|

||||||

|

|

||||||

This is a documentation from someone exploring the code and is by no means complete or even completely accurate. Please edit the parts you might find inaccurate. This is probably going to be helpful nonetheless.

|

|

||||||

|

|

||||||

- [Preset, PresetBundle and PresetCollection](https://github.com/SoftFever/OrcaSlicer/blob/main/doc/developer-reference/Preset-and-bundle.md)

|

|

||||||

- [Plater, Sidebar, Tab, ComboBox](https://github.com/SoftFever/OrcaSlicer/blob/main/doc/developer-reference/plater-sidebar-tab-combobox.md)

|

|

||||||

- [Slicing Call Hierarchy](https://github.com/SoftFever/OrcaSlicer/blob/main/doc/developer-reference/slicing-hierarchy.md)

|

|

||||||

|

|

@ -1,23 +1,25 @@

|

||||||

|

# Application Structure Overview

|

||||||

|

|

||||||

### !! incomplete, possibly inaccurate, being updated with new info !!

|

### !! incomplete, possibly inaccurate, being updated with new info !!

|

||||||

|

|

||||||

## [`Plater`](../../src/slic3r/GUI/Plater.hpp)

|

## [`Plater`](https://github.com/SoftFever/OrcaSlicer/blob/main/src/slic3r/GUI/Plater.hpp)

|

||||||

|

|

||||||

Refers to the entire application. The whole view, file loading, project saving and loading is all managed by this class. This class contains members for the model viewer, the sidebar, gcode viewer and everything else.

|

Refers to the entire application. The whole view, file loading, project saving and loading is all managed by this class. This class contains members for the model viewer, the sidebar, gcode viewer and everything else.

|

||||||

|

|

||||||

## [`Sidebar`](../../src/slic3r/GUI/Plater.hpp)

|

## [`Sidebar`](https://github.com/SoftFever/OrcaSlicer/blob/main/src/slic3r/GUI/Plater.hpp)

|

||||||

|

|

||||||

This is relating the the sidebar in the application window

|

This is relating the the sidebar in the application window

|

||||||

|

|

||||||

<img src="../images/full-sidebar.png" alt="Example Image" width="320">

|

|

||||||

|

|

||||||

## [`ComboBox`](../../src/slic3r/GUI/Widgets/ComboBox.hpp)

|

## [`ComboBox`](https://github.com/SoftFever/OrcaSlicer/blob/main/src/slic3r/GUI/Widgets/ComboBox.hpp)

|

||||||

|

|

||||||

The drop down menus where you can see and select presets

|

The drop down menus where you can see and select presets

|

||||||

|

|

||||||

<img src="../images/combobox.png" alt="Example Image" width="320">

|

|

||||||

|

|

||||||

## [`Tab`](../../src/slic3r/GUI/Tab.hpp)

|

## [`Tab`](https://github.com/SoftFever/OrcaSlicer/blob/main/src/slic3r/GUI/Tab.hpp)

|

||||||

|

|

||||||

Refers to the various windows with settings. e.g. the Popup to edit printer or filament preset. Also the section to edit process preset and the object list. These 4 are managed by `TabPrinter`, `TabFilament`, `TabPrint` and `TabPrintModel` respectively.

|

Refers to the various windows with settings. e.g. the Popup to edit printer or filament preset. Also the section to edit process preset and the object list. These 4 are managed by `TabPrinter`, `TabFilament`, `TabPrint` and `TabPrintModel` respectively.

|

||||||

|

|

||||||

<img src="../images/tab-popup.png" alt="Example Image" width="320">

|

|

||||||

|

Before Width: | Height: | Size: 24 KiB |

|

Before Width: | Height: | Size: 36 KiB |

|

Before Width: | Height: | Size: 24 KiB |

|

Before Width: | Height: | Size: 773 KiB After Width: | Height: | Size: 773 KiB |

|

Before Width: | Height: | Size: 783 KiB After Width: | Height: | Size: 783 KiB |

|

Before Width: | Height: | Size: 68 KiB After Width: | Height: | Size: 68 KiB |

3

doc/images/PreciseWall/PreciseWallOff.svg

Normal file

|

|

@ -0,0 +1,3 @@

|

||||||

|

<?xml version="1.0" encoding="UTF-8"?>

|

||||||

|

<!DOCTYPE svg PUBLIC "-//W3C//DTD SVG 1.1//EN" "http://www.w3.org/Graphics/SVG/1.1/DTD/svg11.dtd">

|

||||||

|

<svg xmlns="http://www.w3.org/2000/svg" style="background: transparent; background-color: transparent; color-scheme: light dark;" xmlns:xlink="http://www.w3.org/1999/xlink" version="1.1" width="401px" height="71px" viewBox="-0.5 -0.5 401 71"><defs/><g><g data-cell-id="0"><g data-cell-id="1"><g data-cell-id="fhMGX1kBES0GxHB0cy2X-14"><g><rect x="130" y="0" width="140" height="70" rx="25.9" ry="25.9" fill-opacity="0.75" fill="#e3c800" style="fill: light-dark(rgb(227, 200, 0), rgb(103, 80, 0)); stroke: light-dark(rgb(176, 149, 0), rgb(141, 118, 0));" stroke="#b09500" stroke-opacity="0.75" pointer-events="all"/></g><g><g transform="translate(-0.5 -0.5)"><switch><foreignObject style="overflow: visible; text-align: left;" pointer-events="none" width="100%" height="100%" requiredFeatures="http://www.w3.org/TR/SVG11/feature#Extensibility"><div xmlns="http://www.w3.org/1999/xhtml" style="display: flex; align-items: unsafe center; justify-content: unsafe center; width: 138px; height: 1px; padding-top: 35px; margin-left: 131px;"><div style="box-sizing: border-box; font-size: 0; text-align: center; color: #000000; "><div style="display: inline-block; font-size: 12px; font-family: "Helvetica"; color: light-dark(#000000, #ededed); line-height: 1.2; pointer-events: all; white-space: normal; word-wrap: normal; ">Inner wall</div></div></div></foreignObject><text x="200" y="39" fill="#000000" font-family=""Helvetica"" font-size="12px" text-anchor="middle">Inner wall</text></switch></g></g></g><g data-cell-id="fhMGX1kBES0GxHB0cy2X-15"><g><rect x="260" y="0" width="140" height="70" rx="25.9" ry="25.9" fill-opacity="0.75" fill="#e3c800" style="fill: light-dark(rgb(227, 200, 0), rgb(103, 80, 0)); stroke: light-dark(rgb(176, 149, 0), rgb(141, 118, 0));" stroke="#b09500" stroke-opacity="0.75" pointer-events="all"/></g><g><g transform="translate(-0.5 -0.5)"><switch><foreignObject style="overflow: visible; text-align: left;" pointer-events="none" width="100%" height="100%" requiredFeatures="http://www.w3.org/TR/SVG11/feature#Extensibility"><div xmlns="http://www.w3.org/1999/xhtml" style="display: flex; align-items: unsafe center; justify-content: unsafe center; width: 138px; height: 1px; padding-top: 35px; margin-left: 261px;"><div style="box-sizing: border-box; font-size: 0; text-align: center; color: #000000; "><div style="display: inline-block; font-size: 12px; font-family: "Helvetica"; color: light-dark(#000000, #ededed); line-height: 1.2; pointer-events: all; white-space: normal; word-wrap: normal; ">Inner wall</div></div></div></foreignObject><text x="330" y="39" fill="#000000" font-family=""Helvetica"" font-size="12px" text-anchor="middle">Inner wall</text></switch></g></g></g><g data-cell-id="fhMGX1kBES0GxHB0cy2X-9"><g><rect x="0" y="0" width="140" height="70" rx="25.9" ry="25.9" fill-opacity="0.75" fill="#fa6800" style="fill: light-dark(rgb(250, 104, 0), rgb(233, 107, 18)); stroke: light-dark(rgb(199, 53, 0), rgb(255, 145, 100));" stroke="#c73500" stroke-opacity="0.75" pointer-events="all"/></g><g><g transform="translate(-0.5 -0.5)"><switch><foreignObject style="overflow: visible; text-align: left;" pointer-events="none" width="100%" height="100%" requiredFeatures="http://www.w3.org/TR/SVG11/feature#Extensibility"><div xmlns="http://www.w3.org/1999/xhtml" style="display: flex; align-items: unsafe center; justify-content: unsafe center; width: 138px; height: 1px; padding-top: 35px; margin-left: 1px;"><div style="box-sizing: border-box; font-size: 0; text-align: center; color: #000000; "><div style="display: inline-block; font-size: 12px; font-family: "Helvetica"; color: light-dark(#000000, #ededed); line-height: 1.2; pointer-events: all; white-space: normal; word-wrap: normal; ">Outer wall</div></div></div></foreignObject><text x="70" y="39" fill="#000000" font-family=""Helvetica"" font-size="12px" text-anchor="middle">Outer wall</text></switch></g></g></g></g></g></g></svg>

|

||||||

|

After Width: | Height: | Size: 4 KiB |

3

doc/images/PreciseWall/PreciseWallOn.svg

Normal file

|

|

@ -0,0 +1,3 @@

|

||||||

|

<?xml version="1.0" encoding="UTF-8"?>

|

||||||

|

<!DOCTYPE svg PUBLIC "-//W3C//DTD SVG 1.1//EN" "http://www.w3.org/Graphics/SVG/1.1/DTD/svg11.dtd">

|

||||||

|

<svg xmlns="http://www.w3.org/2000/svg" style="background: transparent; background-color: transparent; color-scheme: light dark;" xmlns:xlink="http://www.w3.org/1999/xlink" version="1.1" width="411px" height="71px" viewBox="-0.5 -0.5 411 71"><defs/><g><g data-cell-id="0"><g data-cell-id="1"><g data-cell-id="fhMGX1kBES0GxHB0cy2X-14"><g><rect x="140" y="0" width="140" height="70" rx="25.9" ry="25.9" fill-opacity="0.75" fill="#e3c800" style="fill: light-dark(rgb(227, 200, 0), rgb(103, 80, 0)); stroke: light-dark(rgb(176, 149, 0), rgb(141, 118, 0));" stroke="#b09500" stroke-opacity="0.75" pointer-events="all"/></g><g><g transform="translate(-0.5 -0.5)"><switch><foreignObject style="overflow: visible; text-align: left;" pointer-events="none" width="100%" height="100%" requiredFeatures="http://www.w3.org/TR/SVG11/feature#Extensibility"><div xmlns="http://www.w3.org/1999/xhtml" style="display: flex; align-items: unsafe center; justify-content: unsafe center; width: 138px; height: 1px; padding-top: 35px; margin-left: 141px;"><div style="box-sizing: border-box; font-size: 0; text-align: center; color: #000000; "><div style="display: inline-block; font-size: 12px; font-family: "Helvetica"; color: light-dark(#000000, #ededed); line-height: 1.2; pointer-events: all; white-space: normal; word-wrap: normal; ">Inner wall</div></div></div></foreignObject><text x="210" y="39" fill="#000000" font-family=""Helvetica"" font-size="12px" text-anchor="middle">Inner wall</text></switch></g></g></g><g data-cell-id="fhMGX1kBES0GxHB0cy2X-15"><g><rect x="270" y="0" width="140" height="70" rx="25.9" ry="25.9" fill-opacity="0.75" fill="#e3c800" style="fill: light-dark(rgb(227, 200, 0), rgb(103, 80, 0)); stroke: light-dark(rgb(176, 149, 0), rgb(141, 118, 0));" stroke="#b09500" stroke-opacity="0.75" pointer-events="all"/></g><g><g transform="translate(-0.5 -0.5)"><switch><foreignObject style="overflow: visible; text-align: left;" pointer-events="none" width="100%" height="100%" requiredFeatures="http://www.w3.org/TR/SVG11/feature#Extensibility"><div xmlns="http://www.w3.org/1999/xhtml" style="display: flex; align-items: unsafe center; justify-content: unsafe center; width: 138px; height: 1px; padding-top: 35px; margin-left: 271px;"><div style="box-sizing: border-box; font-size: 0; text-align: center; color: #000000; "><div style="display: inline-block; font-size: 12px; font-family: "Helvetica"; color: light-dark(#000000, #ededed); line-height: 1.2; pointer-events: all; white-space: normal; word-wrap: normal; ">Inner wall</div></div></div></foreignObject><text x="340" y="39" fill="#000000" font-family=""Helvetica"" font-size="12px" text-anchor="middle">Inner wall</text></switch></g></g></g><g data-cell-id="fhMGX1kBES0GxHB0cy2X-9"><g><rect x="0" y="0" width="140" height="70" rx="25.9" ry="25.9" fill-opacity="0.75" fill="#fa6800" style="fill: light-dark(rgb(250, 104, 0), rgb(233, 107, 18)); stroke: light-dark(rgb(199, 53, 0), rgb(255, 145, 100));" stroke="#c73500" stroke-opacity="0.75" pointer-events="all"/></g><g><g transform="translate(-0.5 -0.5)"><switch><foreignObject style="overflow: visible; text-align: left;" pointer-events="none" width="100%" height="100%" requiredFeatures="http://www.w3.org/TR/SVG11/feature#Extensibility"><div xmlns="http://www.w3.org/1999/xhtml" style="display: flex; align-items: unsafe center; justify-content: unsafe center; width: 138px; height: 1px; padding-top: 35px; margin-left: 1px;"><div style="box-sizing: border-box; font-size: 0; text-align: center; color: #000000; "><div style="display: inline-block; font-size: 12px; font-family: "Helvetica"; color: light-dark(#000000, #ededed); line-height: 1.2; pointer-events: all; white-space: normal; word-wrap: normal; ">Outer wall</div></div></div></foreignObject><text x="70" y="39" fill="#000000" font-family=""Helvetica"" font-size="12px" text-anchor="middle">Outer wall</text></switch></g></g></g></g></g></g></svg>

|

||||||

|

After Width: | Height: | Size: 4 KiB |

|

Before Width: | Height: | Size: 7.2 KiB |

3

doc/images/Tolerance/tolerance_hole.svg

Normal file

|

|

@ -0,0 +1,3 @@

|

||||||

|

<?xml version="1.0" encoding="UTF-8"?>

|

||||||

|

<!DOCTYPE svg PUBLIC "-//W3C//DTD SVG 1.1//EN" "http://www.w3.org/Graphics/SVG/1.1/DTD/svg11.dtd">

|

||||||

|

<svg xmlns="http://www.w3.org/2000/svg" style="background: transparent; background-color: transparent; color-scheme: light dark;" xmlns:xlink="http://www.w3.org/1999/xlink" version="1.1" width="407px" height="317px" viewBox="-0.5 -0.5 407 317"><defs/><g><g data-cell-id="0"><g data-cell-id="1"><g data-cell-id="S3ItyMhgztYiZC9E-VA5-10"><g><path d="M 141.5 8 L 316.5 8 L 404 158 L 404 158 L 316.5 308 L 141.5 308 L 54 158 L 54 158 Z" fill="#009688" style="fill: light-dark(rgb(0, 150, 136), rgb(36, 165, 153)); stroke: light-dark(rgb(0, 0, 0), rgb(255, 255, 255));" stroke="#000000" stroke-width="2" stroke-miterlimit="10" pointer-events="all"/></g></g><g data-cell-id="S3ItyMhgztYiZC9E-VA5-20"><g><ellipse cx="229" cy="158" rx="150" ry="150" fill="transparent" stroke="#000000" style="stroke: light-dark(rgb(0, 0, 0), rgb(255, 255, 255));" stroke-opacity="0.5" stroke-dasharray="3 3" pointer-events="all"/></g></g><g data-cell-id="S3ItyMhgztYiZC9E-VA5-21"><g><ellipse cx="141.5" cy="8.5" rx="2.5" ry="2.5" fill="#000000" style="fill: light-dark(rgb(0, 0, 0), rgb(237, 237, 237)); stroke: light-dark(rgb(0, 0, 0), rgb(255, 255, 255));" stroke="#000000" pointer-events="all"/></g></g><g data-cell-id="S3ItyMhgztYiZC9E-VA5-22"><g><ellipse cx="316.5" cy="8.5" rx="2.5" ry="2.5" fill="#000000" style="fill: light-dark(rgb(0, 0, 0), rgb(237, 237, 237)); stroke: light-dark(rgb(0, 0, 0), rgb(255, 255, 255));" stroke="#000000" pointer-events="all"/></g></g><g data-cell-id="S3ItyMhgztYiZC9E-VA5-23"><g><ellipse cx="141.5" cy="307.5" rx="2.5" ry="2.5" fill="#000000" style="fill: light-dark(rgb(0, 0, 0), rgb(237, 237, 237)); stroke: light-dark(rgb(0, 0, 0), rgb(255, 255, 255));" stroke="#000000" pointer-events="all"/></g></g><g data-cell-id="S3ItyMhgztYiZC9E-VA5-24"><g><ellipse cx="316.5" cy="307.5" rx="2.5" ry="2.5" fill="#000000" style="fill: light-dark(rgb(0, 0, 0), rgb(237, 237, 237)); stroke: light-dark(rgb(0, 0, 0), rgb(255, 255, 255));" stroke="#000000" pointer-events="all"/></g></g><g data-cell-id="S3ItyMhgztYiZC9E-VA5-25"><g><ellipse cx="54.5" cy="158" rx="2.5" ry="2.5" fill="#000000" style="fill: light-dark(rgb(0, 0, 0), rgb(237, 237, 237)); stroke: light-dark(rgb(0, 0, 0), rgb(255, 255, 255));" stroke="#000000" pointer-events="all"/></g></g><g data-cell-id="S3ItyMhgztYiZC9E-VA5-26"><g><ellipse cx="403.5" cy="158" rx="2.5" ry="2.5" fill="#000000" style="fill: light-dark(rgb(0, 0, 0), rgb(237, 237, 237)); stroke: light-dark(rgb(0, 0, 0), rgb(255, 255, 255));" stroke="#000000" pointer-events="all"/></g></g><g data-cell-id="S3ItyMhgztYiZC9E-VA5-27"><g><path d="M 137 8.73 L 4 8" fill="none" stroke="#000000" style="stroke: light-dark(rgb(0, 0, 0), rgb(255, 255, 255));" stroke-miterlimit="10" pointer-events="stroke"/></g></g><g data-cell-id="S3ItyMhgztYiZC9E-VA5-28"><g><path d="M 137 307.86 L 4 307" fill="none" stroke="#000000" style="stroke: light-dark(rgb(0, 0, 0), rgb(255, 255, 255));" stroke-miterlimit="10" pointer-events="stroke"/></g></g><g data-cell-id="S3ItyMhgztYiZC9E-VA5-29"><g><path d="M 14 300.63 L 14 14.37" fill="none" stroke="#000000" style="stroke: light-dark(rgb(0, 0, 0), rgb(255, 255, 255));" stroke-miterlimit="10" pointer-events="stroke"/><path d="M 14 305.88 L 10.5 298.88 L 14 300.63 L 17.5 298.88 Z" fill="#000000" style="fill: light-dark(rgb(0, 0, 0), rgb(255, 255, 255)); stroke: light-dark(rgb(0, 0, 0), rgb(255, 255, 255));" stroke="#000000" stroke-miterlimit="10" pointer-events="all"/><path d="M 14 9.12 L 17.5 16.12 L 14 14.37 L 10.5 16.12 Z" fill="#000000" style="fill: light-dark(rgb(0, 0, 0), rgb(255, 255, 255)); stroke: light-dark(rgb(0, 0, 0), rgb(255, 255, 255));" stroke="#000000" stroke-miterlimit="10" pointer-events="all"/></g><g><g transform="translate(-0.5 -0.5)rotate(-90 14 154.83333333333326)"><switch><foreignObject style="overflow: visible; text-align: left;" pointer-events="none" width="100%" height="100%" requiredFeatures="http://www.w3.org/TR/SVG11/feature#Extensibility"><div xmlns="http://www.w3.org/1999/xhtml" style="display: flex; align-items: unsafe flex-end; justify-content: unsafe center; width: 1px; height: 1px; padding-top: 155px; margin-left: 14px;"><div style="box-sizing: border-box; font-size: 0; text-align: center; color: #000000; "><div style="display: inline-block; font-size: 11px; font-family: "Helvetica"; color: light-dark(#000000, #ffffff); line-height: 1.2; pointer-events: all; white-space: nowrap; "><font face="Verdana">6,00mm</font></div></div></div></foreignObject><text x="14" y="155" fill="light-dark(#000000, #ffffff)" font-family=""Helvetica"" font-size="11px" text-anchor="middle">6,00mm</text></switch></g></g></g></g></g></g></svg>

|

||||||

|

After Width: | Height: | Size: 4.7 KiB |

|

Before Width: | Height: | Size: 10 KiB |

BIN

doc/images/activate_chamber_heater.png

Normal file

|

After Width: | Height: | Size: 79 KiB |

|

Before Width: | Height: | Size: 22 KiB |

|

|

@ -6,7 +6,7 @@ It covers key aspects such as flow rate, pressure advance, temperature towers, r

|

||||||

|

|

||||||

To access the calibration features, you can find them in the **Calibration** section of the Orca Slicer interface.

|

To access the calibration features, you can find them in the **Calibration** section of the Orca Slicer interface.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

> [!IMPORTANT]

|

> [!IMPORTANT]

|

||||||

> After completing the calibration process, remember to create a new project in order to exit the calibration mode.

|

> After completing the calibration process, remember to create a new project in order to exit the calibration mode.

|

||||||

|

|

@ -29,23 +29,23 @@ The recommended order for calibration is as follows:

|

||||||

|

|

||||||

4. **[Retraction](retraction-calib.md)**: Calibrate the retraction settings to minimize stringing and improve print quality. Doing this after Flow and

|

4. **[Retraction](retraction-calib.md)**: Calibrate the retraction settings to minimize stringing and improve print quality. Doing this after Flow and

|

||||||

|

|

||||||

<img src="../../images/retraction_test_print.jpg" alt="Retraction" height="200">

|

<img src="https://github.com/SoftFever/OrcaSlicer/blob/main/doc/images/retraction_test_print.jpg?raw=true" alt="Retraction" height="200">

|

||||||

|

|

||||||

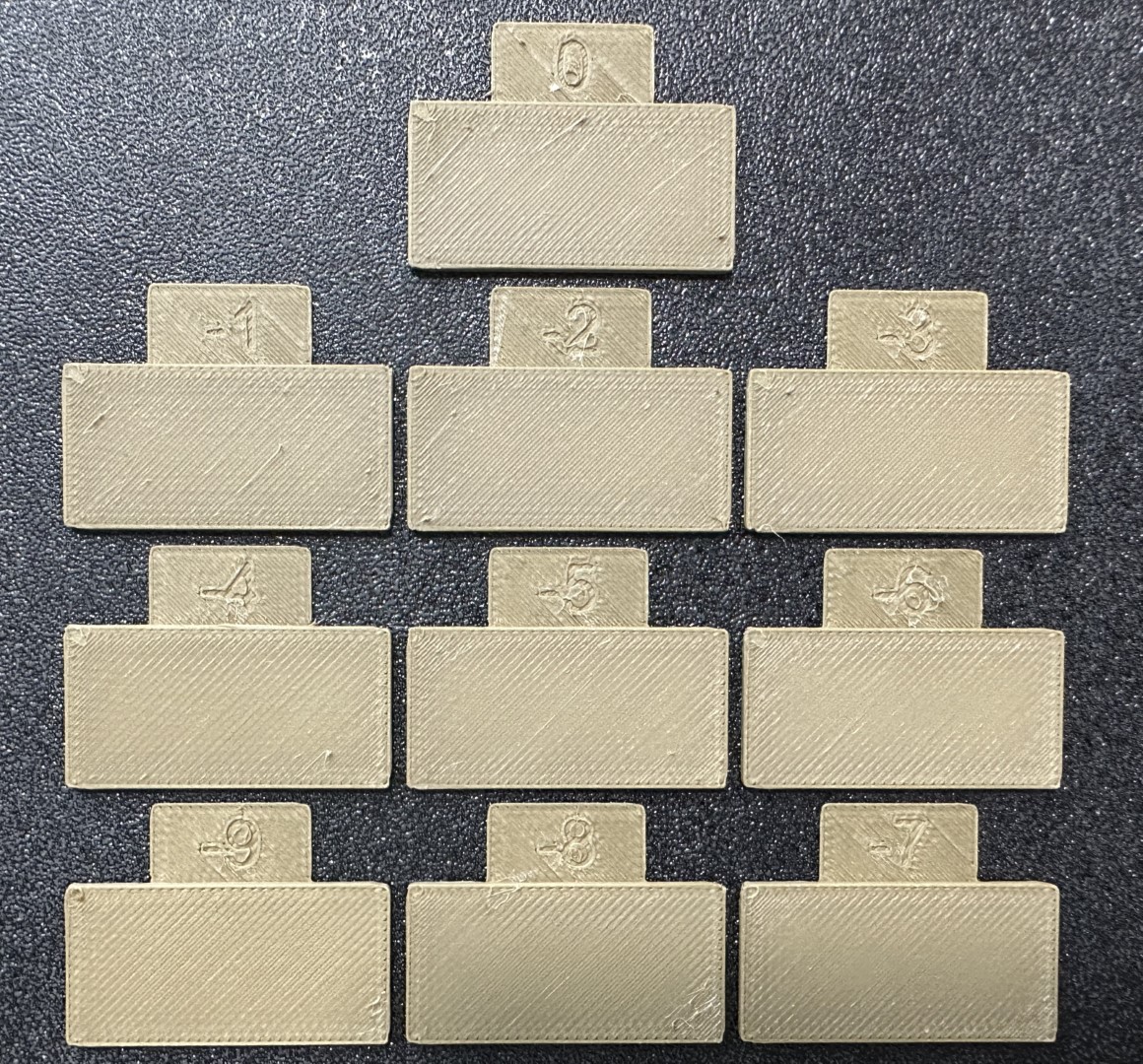

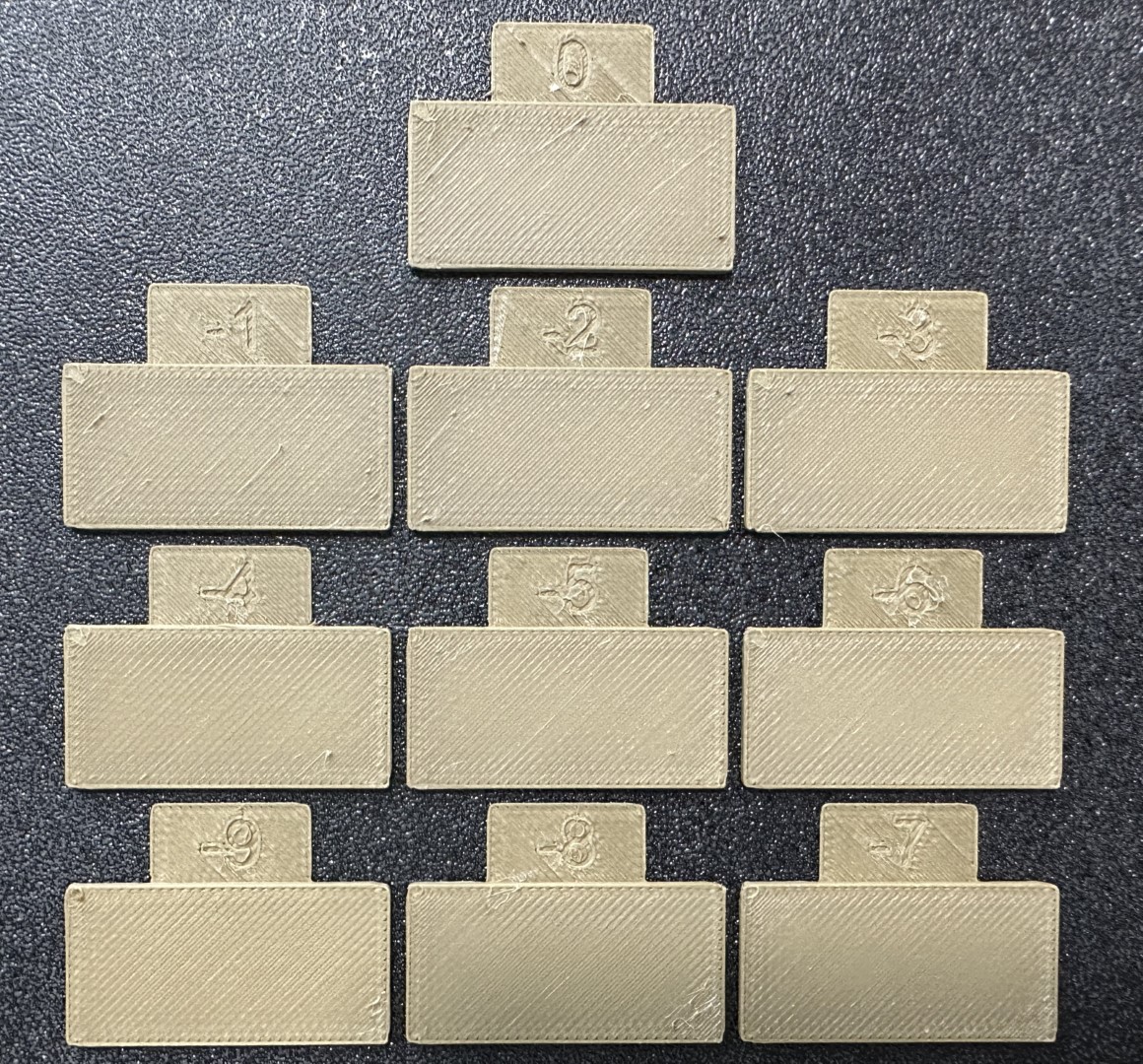

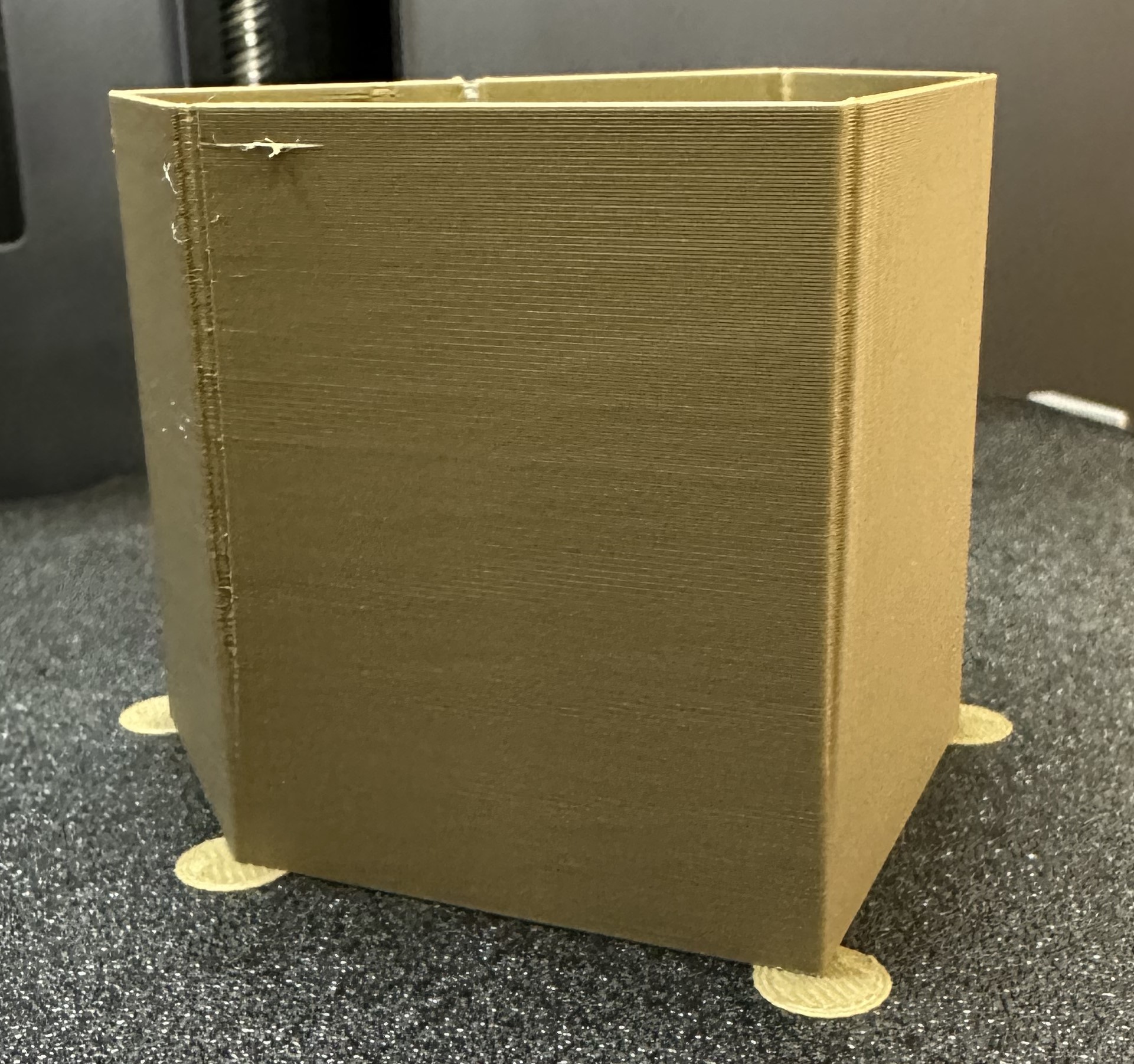

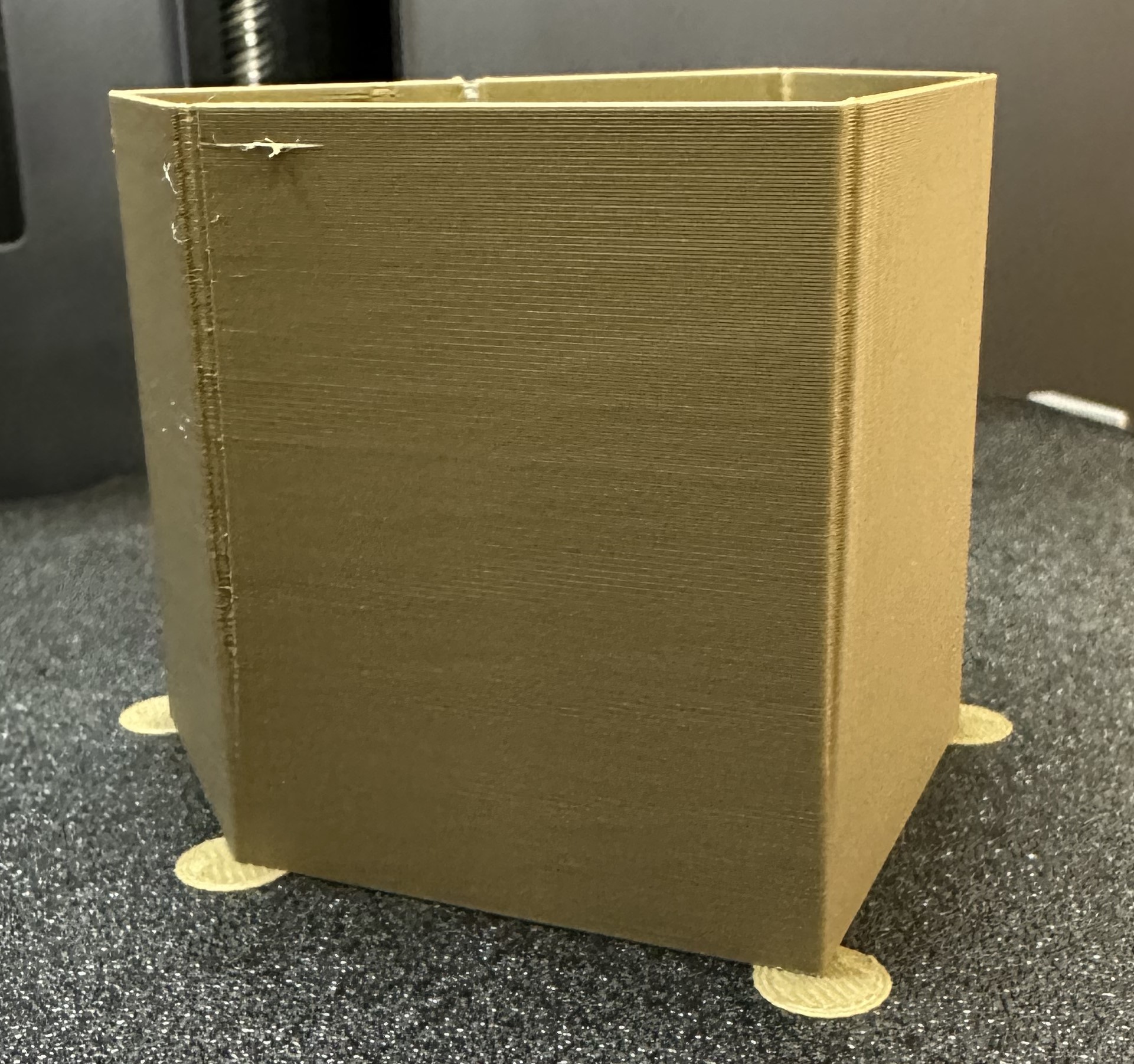

5. **[Tolerance](tolerance-calib.md)**: Calibrate the tolerances of your printer to ensure that it can accurately reproduce the dimensions of the model being printed. This is important for achieving a good fit between parts and for ensuring that the final print meets the desired specifications.

|

5. **[Tolerance](tolerance-calib.md)**: Calibrate the tolerances of your printer to ensure that it can accurately reproduce the dimensions of the model being printed. This is important for achieving a good fit between parts and for ensuring that the final print meets the desired specifications.

|

||||||

|

|

||||||

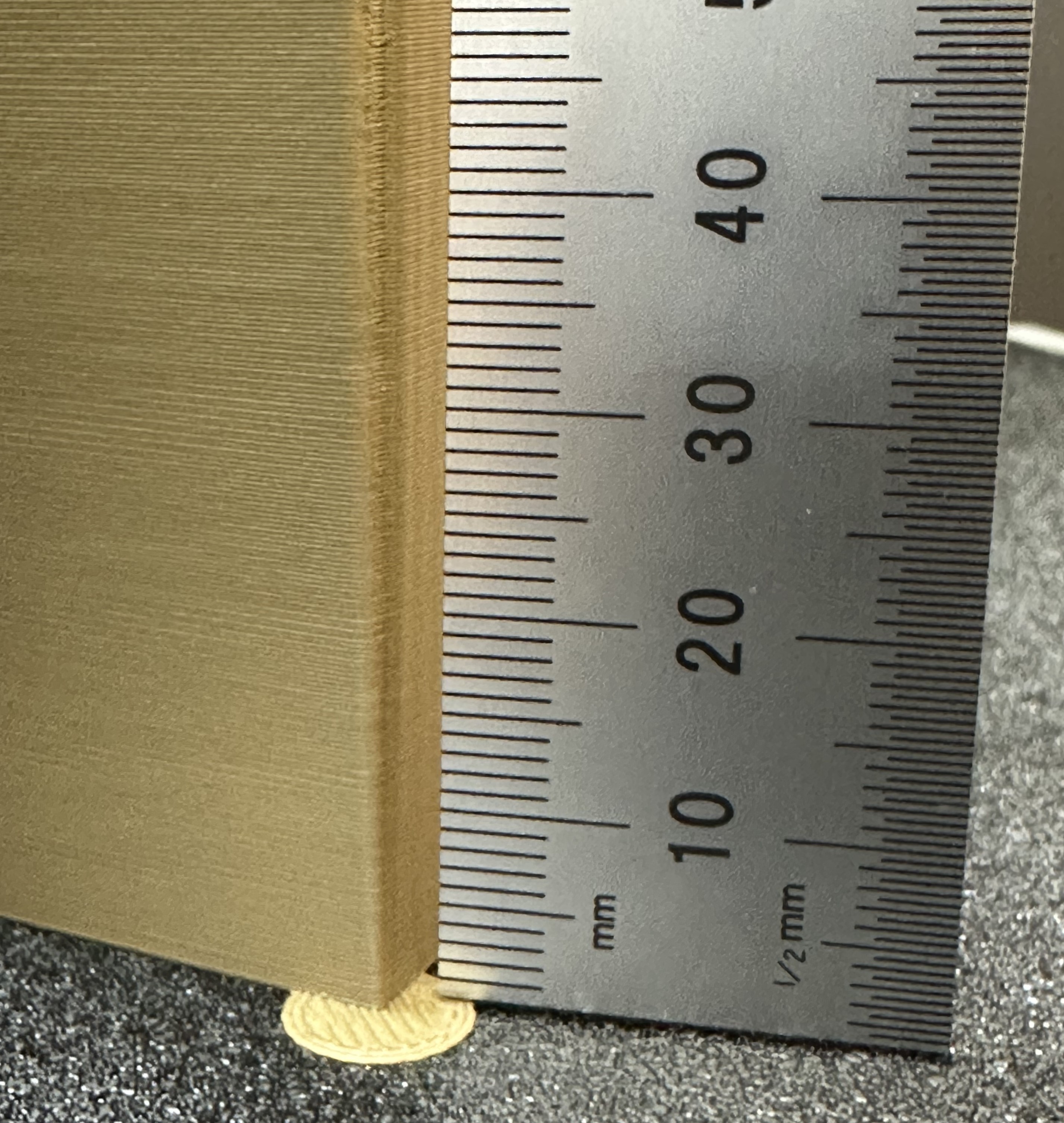

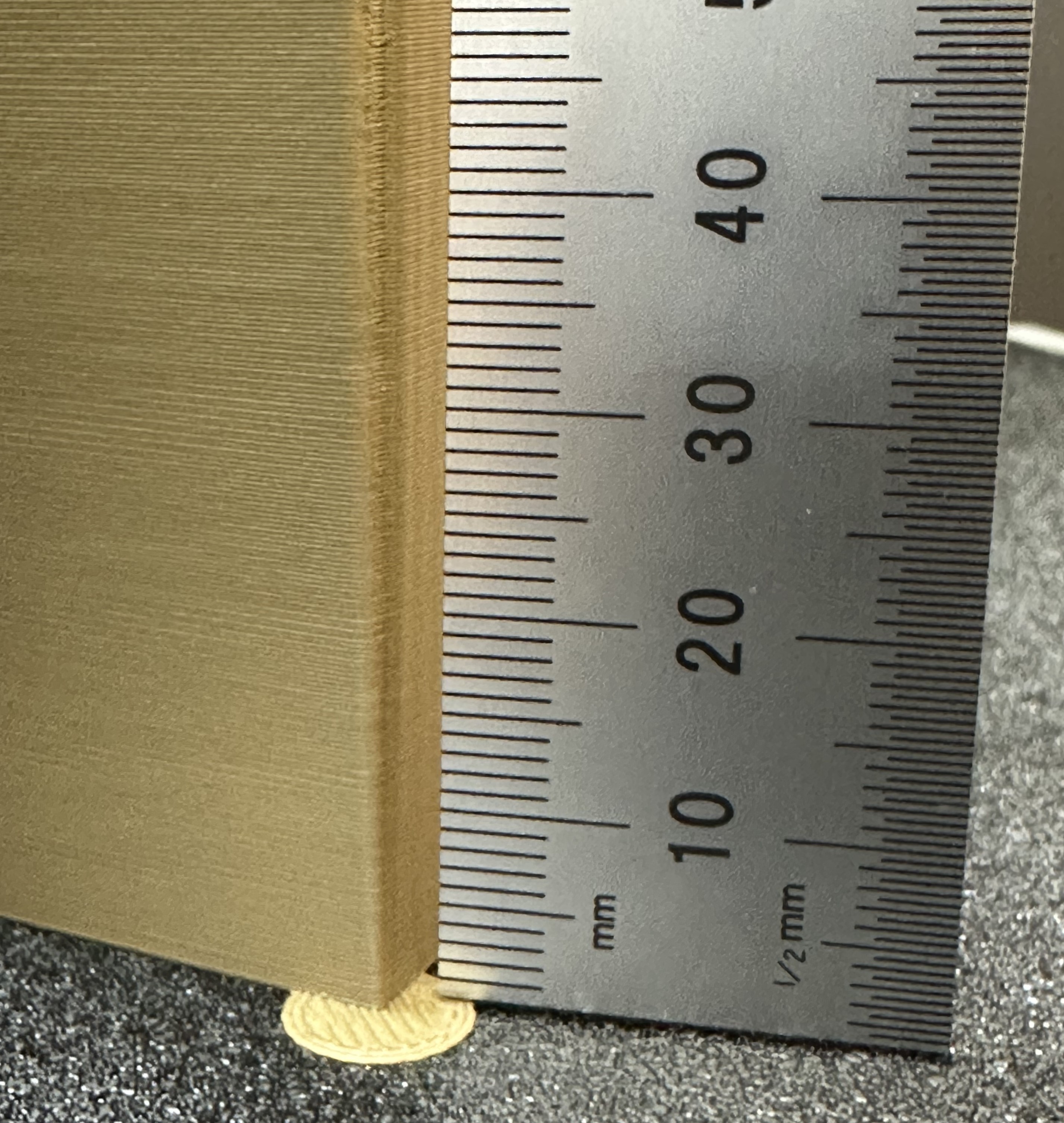

<img src="../../images/Tolerance/OrcaToleranceTes_m6.jpg" alt="Tolerance" height="200">

|

<img src="https://github.com/SoftFever/OrcaSlicer/blob/main/doc/images/Tolerance/OrcaToleranceTes_m6.jpg?raw=true" alt="Tolerance" height="200">

|

||||||

|

|

||||||

6. **[Max Volumetric Speed](volumetric-speed-calib.md)**: Calibrate the maximum volumetric speed of the filament. This is important for ensuring that the printer can handle the flow rate of the filament without causing issues such as under-extrusion or over-extrusion.

|

6. **[Max Volumetric Speed](volumetric-speed-calib.md)**: Calibrate the maximum volumetric speed of the filament. This is important for ensuring that the printer can handle the flow rate of the filament without causing issues such as under-extrusion or over-extrusion.

|

||||||

|

|

||||||

<img src="../../images/vmf_measurement_point.jpg" alt="Max_Volumetric_Speed" height="200">

|

<img src="https://github.com/SoftFever/OrcaSlicer/blob/main/doc/images/vmf_measurement_point.jpg?raw=true" alt="Max_Volumetric_Speed" height="200">

|

||||||

|

|

||||||

7. **[Cornering](cornering-calib.md)**: Calibrate the Jerk/Junction Deviation settings to improve print quality and reduce artifacts caused by sharp corners and changes in direction.

|

7. **[Cornering](cornering-calib.md)**: Calibrate the Jerk/Junction Deviation settings to improve print quality and reduce artifacts caused by sharp corners and changes in direction.

|

||||||

|

|

||||||

<img src="../../images/JunctionDeviation/jd_second_print_measure.jpg" alt="Cornering" height="200">

|

<img src="https://github.com/SoftFever/OrcaSlicer/blob/main/doc/images/JunctionDeviation/jd_second_print_measure.jpg?raw=true" alt="Cornering" height="200">

|

||||||

|

|

||||||

8. **[Input Shaping](input-shaping-calib.md)**: This is an advanced calibration technique that can be used to reduce ringing and improve print quality by compensating for mechanical vibrations in the printer.

|

8. **[Input Shaping](input-shaping-calib.md)**: This is an advanced calibration technique that can be used to reduce ringing and improve print quality by compensating for mechanical vibrations in the printer.

|

||||||

|

|

||||||

<img src="../../images/InputShaping/IS_damp_marlin_print_measure.jpg" alt="Input_Shaping" height="200">

|

<img src="https://github.com/SoftFever/OrcaSlicer/blob/main/doc/images/InputShaping/IS_damp_marlin_print_measure.jpg?raw=true" alt="Input_Shaping" height="200">

|

||||||

|

|

||||||

### VFA

|

### VFA

|

||||||

|

|

||||||

|

|

|

||||||

|

|

@ -138,11 +138,11 @@ It is recommended that the PA step is set to a small value, to allow you to make

|

||||||

|

|

||||||

PA pattern calibration configuration window have been changed to simplify test setup. Now all is needed is to fill list of accelerations and speeds into relevant fields of the calibration window:

|

PA pattern calibration configuration window have been changed to simplify test setup. Now all is needed is to fill list of accelerations and speeds into relevant fields of the calibration window:

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

Test patterns generated for each acceleration-speed pair and all parameters are set accordingly. No additional actions needed from user side. Just slice and print all plates generated.

|

Test patterns generated for each acceleration-speed pair and all parameters are set accordingly. No additional actions needed from user side. Just slice and print all plates generated.

|

||||||

|

|

||||||

Refer to [Calibration Guide](./Calibration) for more details on batch mode calibration.

|

Refer to [Calibration Guide](Calibration) for more details on batch mode calibration.

|

||||||

|

|

||||||

#### OrcaSlicer 2.2.0 and older

|

#### OrcaSlicer 2.2.0 and older

|

||||||

|

|

||||||

|

|

|

||||||

|

|

@ -20,22 +20,22 @@ The default value in Marlin is typically set to 0.08mm, which may be too high fo

|

||||||

3. Use an opaque, high-gloss filament to make the ringing more visible.

|

3. Use an opaque, high-gloss filament to make the ringing more visible.

|

||||||

2. You need to print the Junction Deviation test.

|

2. You need to print the Junction Deviation test.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

1. Measure the X and Y heights and read the frequency set at that point in Orca Slicer.

|

1. Measure the X and Y heights and read the frequency set at that point in Orca Slicer.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

2. It’s very likely that you’ll need to set values lower than 0.08 mm, as shown in the previous example. To determine a more accurate maximum JD value, you can print a new calibration tower with a maximum value set at the point where the corners start losing sharpness.

|

2. It’s very likely that you’ll need to set values lower than 0.08 mm, as shown in the previous example. To determine a more accurate maximum JD value, you can print a new calibration tower with a maximum value set at the point where the corners start losing sharpness.

|

||||||

3. Print the second Junction Deviation test with the new maximum value.

|

3. Print the second Junction Deviation test with the new maximum value.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

4. Measure the X and Y heights and read the frequency set at that point in Orca Slicer.

|

4. Measure the X and Y heights and read the frequency set at that point in Orca Slicer.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

3. Save the settings

|

3. Save the settings

|

||||||

1. Set your Maximun Junction Deviation value in [Printer settings/Motion ability/Jerk limitation].

|

1. Set your Maximun Junction Deviation value in [Printer settings/Motion ability/Jerk limitation].

|

||||||

|

|

|

||||||

|

|

@ -10,7 +10,7 @@ The Flow Ratio determines how much filament is extruded and plays a key role in

|

||||||

> [!IMPORTANT]

|

> [!IMPORTANT]

|

||||||

> PASS 1 and PASS 2 follow the older flow ratio formula `FlowRatio_old*(100 + modifier)/100`. YOLO (Recommended) and YOLO (perfectist version) use a new system that is very simple `FlowRatio_old±modifier`.

|

> PASS 1 and PASS 2 follow the older flow ratio formula `FlowRatio_old*(100 + modifier)/100`. YOLO (Recommended) and YOLO (perfectist version) use a new system that is very simple `FlowRatio_old±modifier`.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

Calibrating the flow rate involves a two-step process.

|

Calibrating the flow rate involves a two-step process.

|

||||||

|

|

||||||

|

|

@ -27,7 +27,7 @@ Calibrating the flow rate involves a two-step process.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

> [!TIP]

|

> [!TIP]

|

||||||

> @ItsDeidara has made a html to help with the calculation. Check it out if those equations give you a headache [here](https://github.com/ItsDeidara/Orca-Slicer-Assistant).

|

> @ItsDeidara has made a html to help with the calculation. Check it out if those equations give you a headache [here](https://github.com/ItsDeidara/Orca-Slicer-Assistant).

|

||||||

|

|

@ -32,12 +32,12 @@ Ussualy the recommended values modes are `MZV` or `EI` for Delta printers.

|

||||||

3. Use an opaque, high-gloss filament to make the ringing more visible.

|

3. Use an opaque, high-gloss filament to make the ringing more visible.

|

||||||

2. Print the Input Shaping Frequency test with a range of frequencies.

|

2. Print the Input Shaping Frequency test with a range of frequencies.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

1. Measure the X and Y heights and read the frequency set at that point in Orca Slicer.

|

1. Measure the X and Y heights and read the frequency set at that point in Orca Slicer.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

2. If not a clear result, you can measure a X and Y min and max acceptable heights and repeat the test with that min and max value.

|

2. If not a clear result, you can measure a X and Y min and max acceptable heights and repeat the test with that min and max value.

|

||||||

|

|

||||||

|

|

@ -46,12 +46,12 @@ Ussualy the recommended values modes are `MZV` or `EI` for Delta printers.

|

||||||

|

|

||||||

3. Print the Damping test setting your X and Y frequency to the value you found in the previous step.

|

3. Print the Damping test setting your X and Y frequency to the value you found in the previous step.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

1. Measure the X and Y heights and read the damping set at that point in Orca Slicer.

|

1. Measure the X and Y heights and read the damping set at that point in Orca Slicer.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

> [!Important]

|

> [!Important]

|

||||||

> Not all Resonance Compensation modes support damping.

|

> Not all Resonance Compensation modes support damping.

|

||||||

|

|

@ -78,12 +78,12 @@ ZV Input Shaping introduces an anti-vibration signal into the stepper motion for

|

||||||

2. Use an opaque, high-gloss filament to make the ringing more visible.

|

2. Use an opaque, high-gloss filament to make the ringing more visible.

|

||||||

2. Print the Input Shaping Frequency test with a range of frequencies.

|

2. Print the Input Shaping Frequency test with a range of frequencies.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

1. Measure the X and Y heights and read the frequency set at that point in Orca Slicer.

|

1. Measure the X and Y heights and read the frequency set at that point in Orca Slicer.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

2. If not a clear result, you can measure a X and Y min and max acceptable heights and repeat the test with that min and max value.

|

2. If not a clear result, you can measure a X and Y min and max acceptable heights and repeat the test with that min and max value.

|

||||||

|

|

||||||

|

|

@ -92,12 +92,12 @@ ZV Input Shaping introduces an anti-vibration signal into the stepper motion for

|

||||||

|

|

||||||

3. Print the Damping test setting your X and Y frequency to the value you found in the previous step.

|

3. Print the Damping test setting your X and Y frequency to the value you found in the previous step.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

1. Measure the X and Y heights and read the damping set at that point in Orca Slicer.

|

1. Measure the X and Y heights and read the damping set at that point in Orca Slicer.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

4. Restore your 3D Printer settings to avoid keep using high acceleration and jerk values.

|

4. Restore your 3D Printer settings to avoid keep using high acceleration and jerk values.

|

||||||

1. Reboot your printer.

|

1. Reboot your printer.

|

||||||

|

|

@ -122,4 +122,4 @@ ZV Input Shaping introduces an anti-vibration signal into the stepper motion for

|

||||||

|

|

||||||

### Fixed-Time Motion

|

### Fixed-Time Motion

|

||||||

|

|

||||||

TODO This calibration test is currently under development. See the [Marlin documentation](https://marlinfw.org/docs/gcode/M493.html) for more information.

|

TODO This calibration test is currently under development. See the [Marlin documentation](https://marlinfw.org/docs/gcode/M493.html) for more information.

|

||||||

|

|

@ -5,7 +5,7 @@ Pressure Advance is a feature that compensates for the lag in filament pressure

|

||||||

Orca Slicer includes three approaches for calibrating the pressure advance value. Each method has its own advantages and disadvantages. It is important to note that each method has two versions: one for a direct drive extruder and one for a Bowden extruder. Make sure to select the appropriate version for your test.

|

Orca Slicer includes three approaches for calibrating the pressure advance value. Each method has its own advantages and disadvantages. It is important to note that each method has two versions: one for a direct drive extruder and one for a Bowden extruder. Make sure to select the appropriate version for your test.

|

||||||

|

|

||||||

> [!NOTE]

|

> [!NOTE]

|

||||||

> [Adaptive Pressure Advance Guide](print_settings/calibration/adaptive-pressure-advance-calib.md)

|

> [Adaptive Pressure Advance Guide](adaptive-pressure-advance-calib)

|

||||||

|

|

||||||

> [!WARNING]

|

> [!WARNING]

|

||||||

> For Marlin: Linear advance must be enabled in firmware (M900). **Not all printers have it enabled by default.**

|

> For Marlin: Linear advance must be enabled in firmware (M900). **Not all printers have it enabled by default.**

|

||||||

|

|

@ -29,7 +29,7 @@ Steps:

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

## Pattern method

|

## Pattern method

|

||||||

|

|

||||||

The pattern method is adapted from [Andrew Ellis' pattern method generator](https://ellis3dp.com/Pressure_Linear_Advance_Tool/), which was itself derived from the [Marlin pattern method](https://marlinfw.org/tools/lin_advance/k-factor.html) developed by [Sineos](https://github.com/Sineos/k-factorjs).

|

The pattern method is adapted from [Andrew Ellis' pattern method generator](https://ellis3dp.com/Pressure_Linear_Advance_Tool/), which was itself derived from the [Marlin pattern method](https://marlinfw.org/tools/lin_advance/k-factor.html) developed by [Sineos](https://github.com/Sineos/k-factorjs).

|

||||||

|

|

@ -39,20 +39,20 @@ The pattern method is adapted from [Andrew Ellis' pattern method generator](http

|

||||||

Test configuration window allow user to generate one or more tests in a single projects. Multiple tests will be placed on each plate with extra plates added if needed.

|

Test configuration window allow user to generate one or more tests in a single projects. Multiple tests will be placed on each plate with extra plates added if needed.

|

||||||

|

|

||||||

1. Single test \

|

1. Single test \

|

||||||

|

|

||||||

2. Batch mode testing (multiple tests on a sinle plate) \

|

2. Batch mode testing (multiple tests on a sinle plate) \

|

||||||

|

|

||||||

|

|

||||||

Once test generated, one or more small rectangular prisms could be found on the plate, one for each test case. This object serves a few purposes:

|

Once test generated, one or more small rectangular prisms could be found on the plate, one for each test case. This object serves a few purposes:

|

||||||

|

|

||||||

1. The test pattern itself is added in as custom G-Code at each layer, same as you could do by hand actually. The rectangular prism gives us the layers in which to insert that G-Code. This also means that **you'll see the full test pattern when you move to the Preview pane**:

|

1. The test pattern itself is added in as custom G-Code at each layer, same as you could do by hand actually. The rectangular prism gives us the layers in which to insert that G-Code. This also means that **you'll see the full test pattern when you move to the Preview pane**:

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

1. The prism acts as a handle, enabling you to move the test pattern wherever you'd like on the plate by moving the prism

|

1. The prism acts as a handle, enabling you to move the test pattern wherever you'd like on the plate by moving the prism

|

||||||

2. Each test object is pre-configured with target parameters which are reflected in the objects name. However, test parameters may be adjusted for each prism individually by referring to the object list pane:

|

2. Each test object is pre-configured with target parameters which are reflected in the objects name. However, test parameters may be adjusted for each prism individually by referring to the object list pane:

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

Next, Ellis' generator provided the ability to adjust specific printer, filament, and print profile settings. You can make these same changes in Orca Slicer by adjusting the settings in the Prepare pane as you would with any other print. When you initiate the calibration test, Ellis' default settings are applied. A few things to note about these settings:

|

Next, Ellis' generator provided the ability to adjust specific printer, filament, and print profile settings. You can make these same changes in Orca Slicer by adjusting the settings in the Prepare pane as you would with any other print. When you initiate the calibration test, Ellis' default settings are applied. A few things to note about these settings:

|

||||||

|

|

||||||

|

|

@ -69,9 +69,8 @@ The PA value for this test will be increased by 0.002 for every 1 mm increase in

|

||||||

1. Select the printer, filament, and process you would like to use for the test.

|

1. Select the printer, filament, and process you would like to use for the test.

|

||||||

2. Examine each corner of the print and mark the height that yields the best overall result.

|

2. Examine each corner of the print and mark the height that yields the best overall result.

|

||||||

3. I selected a height of 8 mm for this case, so the pressure advance value should be calculated as `PressureAdvanceStart+(PressureAdvanceStep x measured)` example: `0+(0.002 x 8) = 0.016`.

|

3. I selected a height of 8 mm for this case, so the pressure advance value should be calculated as `PressureAdvanceStart+(PressureAdvanceStep x measured)` example: `0+(0.002 x 8) = 0.016`.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

> [!TIP]

|

> [!TIP]

|

||||||

> @ItsDeidara has made a html to help with the calculation. Check it out if those equations give you a headache [here](https://github.com/ItsDeidara/Orca-Slicer-Assistant).

|

> @ItsDeidara has made a html to help with the calculation. Check it out if those equations give you a headache [here](https://github.com/ItsDeidara/Orca-Slicer-Assistant).

|

||||||

|

|

@ -4,13 +4,13 @@ Retraction is the process of pulling the filament back into the nozzle to preven

|

||||||

|

|

||||||

This test generates a retraction tower automatically. The retraction tower is a vertical structure with multiple notches, each printed at a different retraction length. After the print is complete, we can examine each section of the tower to determine the optimal retraction length for the filament. The optimal retraction length is the shortest one that produces the cleanest tower.

|

This test generates a retraction tower automatically. The retraction tower is a vertical structure with multiple notches, each printed at a different retraction length. After the print is complete, we can examine each section of the tower to determine the optimal retraction length for the filament. The optimal retraction length is the shortest one that produces the cleanest tower.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

In the dialog, you can select the start and end retraction length, as well as the retraction length increment step. The default values are 0mm for the start retraction length, 2mm for the end retraction length, and 0.1mm for the step. These values are suitable for most direct drive extruders. However, for Bowden extruders, you may want to increase the start and end retraction lengths to 1mm and 6mm, respectively, and set the step to 0.2mm.

|

In the dialog, you can select the start and end retraction length, as well as the retraction length increment step. The default values are 0mm for the start retraction length, 2mm for the end retraction length, and 0.1mm for the step. These values are suitable for most direct drive extruders. However, for Bowden extruders, you may want to increase the start and end retraction lengths to 1mm and 6mm, respectively, and set the step to 0.2mm.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

> [!NOTE]

|

> [!NOTE]

|

||||||

> When testing filaments such as PLA or ABS that have minimal oozing, the retraction settings can be highly effective. You may find that the retraction tower appears clean right from the start. In such situations, setting the retraction length to 0.2mm - 0.4mm using Orca Slicer should suffice.

|

> When testing filaments such as PLA or ABS that have minimal oozing, the retraction settings can be highly effective. You may find that the retraction tower appears clean right from the start. In such situations, setting the retraction length to 0.2mm - 0.4mm using Orca Slicer should suffice.

|

||||||

|

|

|

||||||

|

|

@ -7,7 +7,7 @@ There is no other calibration that can have such a big impact on the print quali

|

||||||

|

|

||||||

Nozzle temperature is one of the most important settings to calibrate for a successful print. The temperature of the nozzle affects the viscosity of the filament, which in turn affects how well it flows through the nozzle and adheres to the print bed. If the temperature is too low, the filament may not flow properly, leading to under-extrusion, poor layer adhesion and stringing. If the temperature is too high, the filament may degrade, over-extrude and produce stringing.

|

Nozzle temperature is one of the most important settings to calibrate for a successful print. The temperature of the nozzle affects the viscosity of the filament, which in turn affects how well it flows through the nozzle and adheres to the print bed. If the temperature is too low, the filament may not flow properly, leading to under-extrusion, poor layer adhesion and stringing. If the temperature is too high, the filament may degrade, over-extrude and produce stringing.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

Temp tower is a straightforward test. The temp tower is a vertical tower with multiple blocks, each printed at a different temperature. Once the print is complete, we can examine each block of the tower and determine the optimal temperature for the filament. The optimal temperature is the one that produces the highest quality print with the least amount of issues, such as stringing, layer adhesion, warping (overhang), and bridging.

|

Temp tower is a straightforward test. The temp tower is a vertical tower with multiple blocks, each printed at a different temperature. Once the print is complete, we can examine each block of the tower and determine the optimal temperature for the filament. The optimal temperature is the one that produces the highest quality print with the least amount of issues, such as stringing, layer adhesion, warping (overhang), and bridging.

|

||||||

|

|

||||||

|

|

@ -23,7 +23,7 @@ This setting doesn't have a specific test, but it is recommended to start with t

|

||||||

|

|

||||||

Chamber temperature can affect the print quality, especially for high-temperature filaments. A heated chamber can help to maintain a consistent temperature throughout the print, reducing the risk of warping and improving layer adhesion. However, it is important to monitor the chamber temperature to ensure that it does not exceed the recommended temperature for the filament being used.

|

Chamber temperature can affect the print quality, especially for high-temperature filaments. A heated chamber can help to maintain a consistent temperature throughout the print, reducing the risk of warping and improving layer adhesion. However, it is important to monitor the chamber temperature to ensure that it does not exceed the recommended temperature for the filament being used.

|

||||||

|

|

||||||

See: [Chamber temperature printer settings](../../Chamber-temperature.md)

|

See: [Chamber temperature printer settings](Chamber-temperature)

|

||||||

|

|

||||||

> [!NOTE]

|

> [!NOTE]

|

||||||

> Low temperature Filaments like PLA can clog the nozzle if the chamber temperature is too high.

|

> Low temperature Filaments like PLA can clog the nozzle if the chamber temperature is too high.

|

||||||

|

|

@ -7,7 +7,7 @@ To correct for these variations, Orca Slicer provides:

|

||||||

|

|

||||||

- Shrinkage (XY)

|

- Shrinkage (XY)

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

- Process Compensation:

|

- Process Compensation:

|

||||||

|

|

||||||

|

|

@ -16,16 +16,16 @@ To correct for these variations, Orca Slicer provides:

|

||||||

- Precise wall

|

- Precise wall

|

||||||

- Precise Z height

|

- Precise Z height

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

## Orca Tolerance Test

|

## Orca Tolerance Test

|

||||||

|

|

||||||

This calibration test is designed to evaluate the dimensional accuracy of your printer and filament. The model consists of a base with six hexagonal holes, each with a different tolerance: 0.0 mm, 0.05 mm, 0.1 mm, 0.2 mm, 0.3 mm, and 0.4 mm, as well as a hexagon-shaped tester.

|

This calibration test is designed to evaluate the dimensional accuracy of your printer and filament. The model consists of a base with six hexagonal holes, each with a different tolerance: 0.0 mm, 0.05 mm, 0.1 mm, 0.2 mm, 0.3 mm, and 0.4 mm, as well as a hexagon-shaped tester.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

You can check the tolerance using either an M6 Allen key or the included printed hexagon tester.

|

You can check the tolerance using either an M6 Allen key or the included printed hexagon tester.

|

||||||

Use calipers to measure both the holes and the inner tester. Based on your results, you can fine-tune the X-Y hole compensation and X-Y contour compensation settings. Repeat the process until you achieve the desired precision.

|

Use calipers to measure both the holes and the inner tester. Based on your results, you can fine-tune the X-Y hole compensation and X-Y contour compensation settings. Repeat the process until you achieve the desired precision.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

|

|

@ -6,15 +6,15 @@ You will be promted to enter the settings for the test: start volumetric speed,

|

||||||

|

|

||||||

Once printed, take note of where the layers begin to fail and where the quality begins to suffer. Pay attention to changes from matte to shiny as well.

|

Once printed, take note of where the layers begin to fail and where the quality begins to suffer. Pay attention to changes from matte to shiny as well.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

Using calipers or a ruler, measure the height of the print at that point. Use the following calculation to determine the correct max flow value: `start + (height-measured * step)` . For example in the photo below, and using the default setting values, the print quality began to suffer at 19mm measured, so the calculation would be: `5 + (19 * 0.5)` , or `13mm³/s` using the default values. Enter your number into the "Max volumetric speed" value in the filament settings.

|

Using calipers or a ruler, measure the height of the print at that point. Use the following calculation to determine the correct max flow value: `start + (height-measured * step)` . For example in the photo below, and using the default setting values, the print quality began to suffer at 19mm measured, so the calculation would be: `5 + (19 * 0.5)` , or `13mm³/s` using the default values. Enter your number into the "Max volumetric speed" value in the filament settings.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

You can also return to OrcaSlicer in the "Preview" tab, make sure the color scheme "flow" is selected. Scroll down to the layer height that you measured, and click on the toolhead slider. This will indicate the max flow level for your filmanet.

|

You can also return to OrcaSlicer in the "Preview" tab, make sure the color scheme "flow" is selected. Scroll down to the layer height that you measured, and click on the toolhead slider. This will indicate the max flow level for your filmanet.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

> [!NOTE]

|

> [!NOTE]

|

||||||

> You may also choose to conservatively reduce the flow by 5-10% to ensure print quality.

|

> You may also choose to conservatively reduce the flow by 5-10% to ensure print quality.

|

||||||

|

|

|

||||||

|

|

@ -6,7 +6,7 @@ This happens by reducing the stresses put on the extrusion system as well as red

|

||||||

|

|

||||||

This feature is especially helpful when printing at high accelerations and large flow rates as the deviations are larger in these cases.

|

This feature is especially helpful when printing at high accelerations and large flow rates as the deviations are larger in these cases.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

## Theory

|

## Theory

|

||||||

|

|

||||||

|

|

@ -17,7 +17,7 @@ This works by breaking down the printed line segments into smaller "chunks", pro

|

||||||

In summary, **it takes the "edge" off rapid extrusion changes caused by acceleration/deceleration as these are now spread over a longer distance and time.** Therefore, it can reduce wall artefacts that show when the print speeds change suddenly. These artefacts are occuring because the extruder and firmware cannot perfectly adhere to the requested by the slicer flow rates, especially when the extrusion rate is changing rapidly.

|

In summary, **it takes the "edge" off rapid extrusion changes caused by acceleration/deceleration as these are now spread over a longer distance and time.** Therefore, it can reduce wall artefacts that show when the print speeds change suddenly. These artefacts are occuring because the extruder and firmware cannot perfectly adhere to the requested by the slicer flow rates, especially when the extrusion rate is changing rapidly.

|

||||||

|

|

||||||

**The example below shows the artefact that is mitigated by ERS.**

|

**The example below shows the artefact that is mitigated by ERS.**

|

||||||

|

|

||||||

|

|

||||||

The bulging visible above is due to the extruder not being able to respond fast enough against the required speed change when printing with high accelerations and high speeds and requested to slow down for an overhang.

|

The bulging visible above is due to the extruder not being able to respond fast enough against the required speed change when printing with high accelerations and high speeds and requested to slow down for an overhang.

|

||||||

|

|

||||||

|

|

@ -43,17 +43,26 @@ When a speed change is requested, the firmware look ahead planner calculates the

|

||||||

|

|

||||||

This deceleration move would happen over approximately 9.6mm. This is derived from the following equation:

|

This deceleration move would happen over approximately 9.6mm. This is derived from the following equation:

|

||||||

|

|

||||||

|

Where:

|

||||||

|

|

||||||

|

- vf = final speed.

|

||||||

|

- vi = initial speed.

|

||||||

|

- a = acceleration (in this case, it will be negative as it's a deceleration).

|

||||||

|

- d = distance.

|

||||||

|

|

||||||

|

```math

|

||||||

|

d = \frac{v_f^2 - v_i^2}{2a}

|

||||||

|

```

|

||||||

|

|

||||||

The time taken to decelerate to this new speed would be approx. 0.08 seconds, derived from the following equation:

|

The time taken to decelerate to this new speed would be approx. 0.08 seconds, derived from the following equation:

|

||||||

|

|

||||||

|

```math

|

||||||

|

t = \frac{v_f - v_i}{a}

|

||||||

|

```

|

||||||

|

|

||||||

A printer printing at 200mm/sec with a 0.42 line width and 0.16 layer height would be extruding plastic at approx. 12.16mm3/sec, as can also be seen from the below visual.

|

A printer printing at 200mm/sec with a 0.42 line width and 0.16 layer height would be extruding plastic at approx. 12.16mm3/sec, as can also be seen from the below visual.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

When the printer is extruding at 40mm/sec with the same line width and layer height as above, the flow rate is 2.43mm3/sec.

|

When the printer is extruding at 40mm/sec with the same line width and layer height as above, the flow rate is 2.43mm3/sec.

|

||||||

|

|

||||||

|

|

|

||||||

|

|

@ -5,7 +5,7 @@ OrcaSlicer primarily relies on STL meshes for slicing, but STL files may come wi

|

||||||

Typically, STL files feature a low polygon count, which can adversely affect print quality.

|

Typically, STL files feature a low polygon count, which can adversely affect print quality.

|

||||||

In contrast, using STEP files offers a higher-quality mesh that more accurately represents the original design. However, be aware that both high-polygon STL and STEP files can increase slicing time.

|

In contrast, using STEP files offers a higher-quality mesh that more accurately represents the original design. However, be aware that both high-polygon STL and STEP files can increase slicing time.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

## Importing STEP files

|

## Importing STEP files

|

||||||

|

|

||||||

|

|

@ -13,14 +13,14 @@ This setting determines how STEP files are converted into STL files and is displ

|

||||||

|

|

||||||

If you don't see this when opening a STEP file, check [Don't show again](#Don't-show-again) below.

|

If you don't see this when opening a STEP file, check [Don't show again](#Don't-show-again) below.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

### Parameters:

|

### Parameters:

|

||||||

|

|

||||||

The transformation uses [Linear Deflection and Angular Deflection](https://dev.opencascade.org/doc/overview/html/occt_user_guides__mesh.html) parameters to control the mesh quality.

|

The transformation uses [Linear Deflection and Angular Deflection](https://dev.opencascade.org/doc/overview/html/occt_user_guides__mesh.html) parameters to control the mesh quality.

|

||||||

A finer mesh will result in a more accurate representation of the original surface, but it will also increase the file size and processing time.

|

A finer mesh will result in a more accurate representation of the original surface, but it will also increase the file size and processing time.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

- **Linear Deflection**: Specifies the maximum distance allowed between the original surface and its polygonal approximation. Lower values produce a mesh that more accurately follows the original curvature.

|

- **Linear Deflection**: Specifies the maximum distance allowed between the original surface and its polygonal approximation. Lower values produce a mesh that more accurately follows the original curvature.

|

||||||

- **Angular Deflection**: Defines the maximum allowable angle difference between the actual surface and its tessellated counterpart. Smaller angular deflection values yield a more precise mesh.

|

- **Angular Deflection**: Defines the maximum allowable angle difference between the actual surface and its tessellated counterpart. Smaller angular deflection values yield a more precise mesh.

|

||||||

|

|

@ -29,14 +29,14 @@ A finer mesh will result in a more accurate representation of the original surfa

|

||||||

|

|

||||||

Enabling this option will split the imported 3D file into separate objects. This is especially useful for adjusting individual object positions, tweaking print settings, or optimizing the model through simplification.

|

Enabling this option will split the imported 3D file into separate objects. This is especially useful for adjusting individual object positions, tweaking print settings, or optimizing the model through simplification.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

#### Don't show again

|

#### Don't show again

|

||||||

|

|

||||||

This option will hide the STL transformation dialog when opening a STEP file.

|

This option will hide the STL transformation dialog when opening a STEP file.

|

||||||

To restore the dialog, go to "Preferences" (Ctrl + P) > "Show the STEP mesh parameter setting dialog".

|

To restore the dialog, go to "Preferences" (Ctrl + P) > "Show the STEP mesh parameter setting dialog".

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

## Simplify model

|

## Simplify model

|

||||||

|

|

||||||

|

|

@ -46,7 +46,7 @@ This function is especially useful for improving the performance of the slicer o

|

||||||

|

|

||||||

To access the Simplify Model option, right-click on the object to simplify in the "Prepare" menu.

|

To access the Simplify Model option, right-click on the object to simplify in the "Prepare" menu.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

It is recommended to enable the "Show Wireframe" option when running a simplification process to visually inspect the outcome. However, be cautious: overly aggressive simplification may lead to noticeable detail loss, increased ringing, or other printing issues.

|

It is recommended to enable the "Show Wireframe" option when running a simplification process to visually inspect the outcome. However, be cautious: overly aggressive simplification may lead to noticeable detail loss, increased ringing, or other printing issues.

|

||||||

|

|

||||||

|

|

|

||||||